can I print faster

I have a MK3S and the part I am printing takes 6 hours. Would another printer do it faster or do other printers just do larger parts?

RE: can I print faster

Details will depend on the part and how much detail you're willing to give up versus speed. If you'd care to save your part and settings off in a 3MF project file, zip it, and attach it to a reply here, we can make more specific suggestions.

In general, a larger nozzle and correspondingly larger setting values will reduce speed more than simply increasing linear speeds. I've got notes on the subject here if you'd care to take a look.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: can I print faster

Six hours is a quick print! 😉

One thing about this whole 3d printing scene is that it's S-L-O-W for anything large and complex.

There's the old saying "Do you want it done right, or do you want it done right now, choose one." 😉

RE: can I print faster

You should not rush perfection. I do fast prints but I trade quality.

--------------------

Chuck H

3D Printer Review Blog

RE: can I print faster

My longest print was over 60 hours and that was with a larger 0.6 nozzle. With. 0.4 it would have been double that. 6 hours is a quick print.

RE: can I print faster

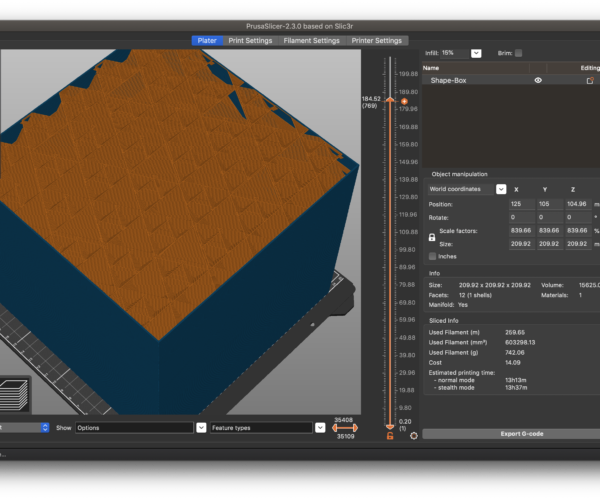

Just for sh*ts and giggles, I just tried slicing a cube which was about as large as I could get in PS without turning blue.

Normal settings I use, .2mm layers, 15% infill.

It would take 5 days and 6 hours to print.

That's probably close to the upper bound of the longest print that can be done on this machine.

RE: can I print faster

I have printed a couple near that long. The longest print on a printer I have done was 8 days on my CR-10 S pro. It took me 3 trys.

--------------------

Chuck H

3D Printer Review Blog

RE: can I print faster

I have a MK3S and the part I am printing takes 6 hours. Would another printer do it faster or do other printers just do larger parts?

Although there are aspects of time governed by the printer, much of the timing is governed by the material and technology you are using. At the end of the day, you can only squeeze PLA (or PETG or whatever) out of a nozzle so fast. You have to push it in the nozzle as a solid, melt it so it flows at the end, and cool it back down so it doesn't lose its shape after you put it down. You can print a larger nozzle diameter, and thus push more plastic faster, but you trade quality. You can the printer faster (to some upper limit), but you typically trade away quality as well. Everything you are doing is a balance of quality, speed, and part strength.

The stepper motors of the MK3S can physically move faster. You hit the limits of the plastic long before you hit the limits of the printer.

Stock Prusa MK3S+ built from kit on 12/2020

OctoPrint, typically print from a drybox, no enclosure yet

Printing proudly since 2011

RE: can I print faster

@bobstro

thanks for your help

RE: can I print faster

@bobstro

RE: can I print faster

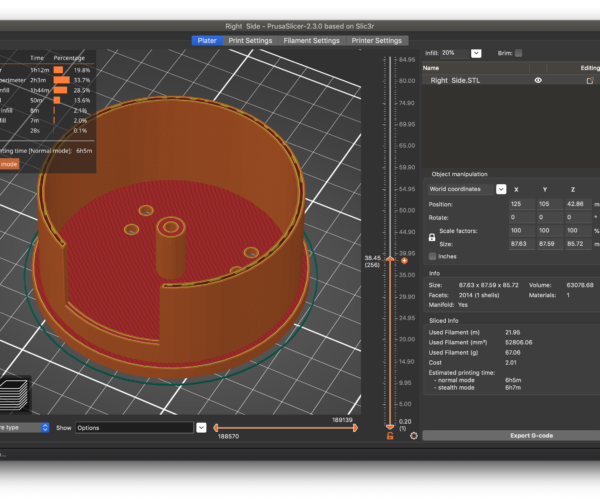

@jerry-s - This print is a good example of where you can make speed-versus-quality trade-offs and dramatically impact your rate of production.

First, I pulled in your settings and observed the following:

- The PrinterSettings show a 0.6mm nozzle diameter with a min layer height of 0.07 and max layer height of 0.25mm.

- You are printing with Prusament PETG at 240-250C with a Max volumetric speed (MVS) of 7mm^3/s.

- You are using a 0.15mm SPEED print settings profile.

- Estimated print time is 6h5m.

Here's what it looks like after slicing:

A few observations:

- Using 2 perimeters at 0.45mm width, the hollow space between the inner and outer walls are being filled with sparse infil at 15%.

- At 0.15mm layer height, you are printing at a very fine level of detail for a part that appears to be intended to be robust and strong.

Next, I replaced your profiles with my 0.4mm nozzle profiles that have been tweaked a bit. The most notable changes are:

- I am using a 0.4mm nozzle with a min layer height of 0.1mm and max layer height of 0.32mm (80% of nozzle size).

- I selected an AmazonBasics PETG at 230-235C with a Max volumetric speed (MVS) of 7mm^3/s (the same).

- I selected a QUALITY profile with 3 perimeters at 0.15mm layer height.

So far, I've more-or-less replicated your settings. In this configuration, the print time actually goes up to 0ver 7h. But here's the fun part:

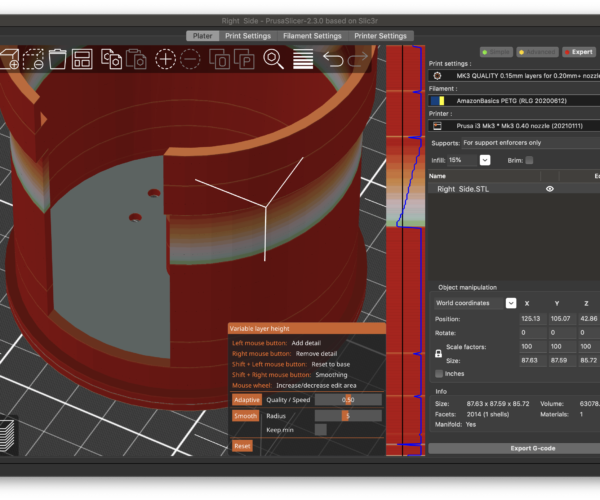

- I selected the part and enabled Variable layer height (VLH) for the part in the slicer. This re-calculated layer heights to maintain quality while using optimized layer heights between my extruder minimum (0.1mm) and maximum (0.32mm).

This adjusted the print to use larger layer heights where little detail is required (the red bits are 0.32mm) and lower layer heights where more detail is required (the green bits are 0.1mm). Here's the result after using VLH with the default settings.

At this point, print time dropped to 4h38m, a reduction of 87m, as shown here:

Observe the following:

- Using 3 perimeters at 0 (auto - slicer calculated) width, the hollow space between the inner and outer walls has been made solid with extra perimeters and gap fill. The resulting part should be much stronger.

- Using VLH, low layer heights have been limited to those areas where it will make a difference. Higher layer heights have been used to reduce print times elsewhere.

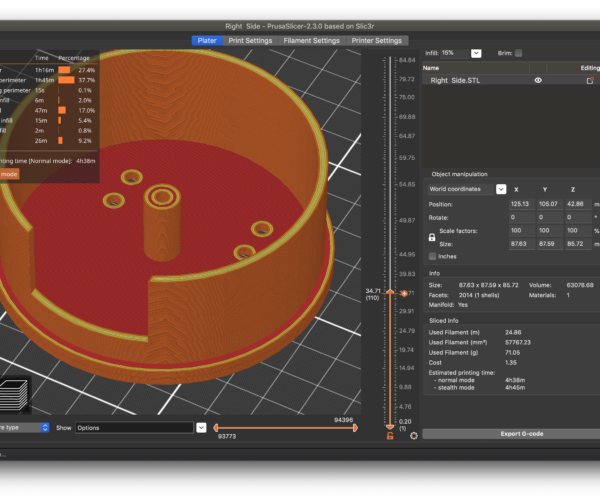

These are fairly minor tweaks that have a big impact both on print time and print robustness. Next I tried essentially the same settings with some tweaks based on experience with this PETG filament.

- I increased my print temperature to 240C, a higher temperature that has worked well for me with this PETG.

- I increased the MVS to 15mm^3/s. This can result in poor infill with PETG, but there's really no infill on this print. No need to hold the flow rate back. The MVS values provided with PrusaSlicer are optimized for a 0.4mm nozzle. A 0.6mm nozzle has far less back pressure, so you can greatly increase MVS with the appropriate filament. PETG flows well at higher temps.

- I tweaked my external perimeter and top infill speeds from 25mm/s for quality to 45mm/s for a bit more speed.

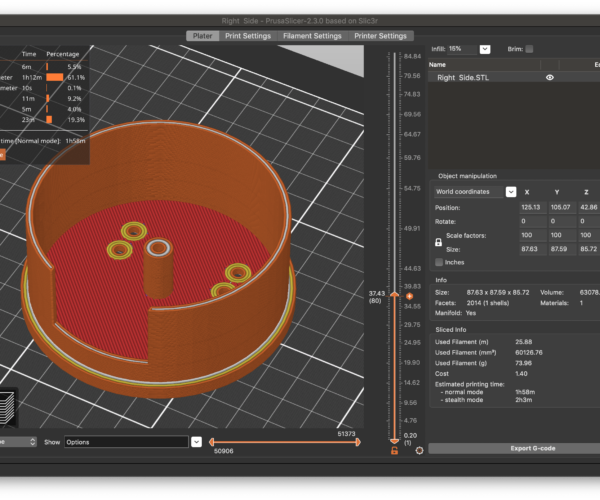

This reduced the estimated print time down to 3h19m, a savings of 166m. Next, I went with a full set of optimization for speed. These are roughly the same settings I used while printing PPE early in 2020.

- I selected a 0.6mm nozzle profile with a minimum layer height of 0.1mm and a maximum layer height of 0.48mm.

- I selected a "Max PPE PETG" profile printing at 240-245C with MVS of 28mm^3/s (the result of a lot of testing).

- I adjusted the default extrusion width to 1mm.

- I reset and readjusted VLH for the part.

Here is the result:

Observe the following:

- The wall perimeters are down to 3 extrusions due to the wider extrusion width. This saves a lot of time printing.

- Layer heights are now distributed from 0.1mm to 0.48mm based on my nozzle (extruder) settings.

- The base is now solid with no sparse infill. The walls are thick and strong. The part should be very robust.

- Print time is down to 1h58m, a savings of 354m.

Now I'm not saying you should immediately start using these settings, or guaranteeing great results using them. I just want to emphasize the fact that if you get to know the limits of your slicer, printer, and filament, there are relatively minor tweaks you can make that will make a huge difference in print time. The acceptable balance of quality-versus-speed is something only you can determine.

Here are pics of my results with similar settings. First, overhang quality:

Next, part strength:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: can I print faster

@bobstro

How does one find the setting for variable layer height in the slicer?

RE: can I print faster

[...] How does one find the setting for variable layer height in the slicer?

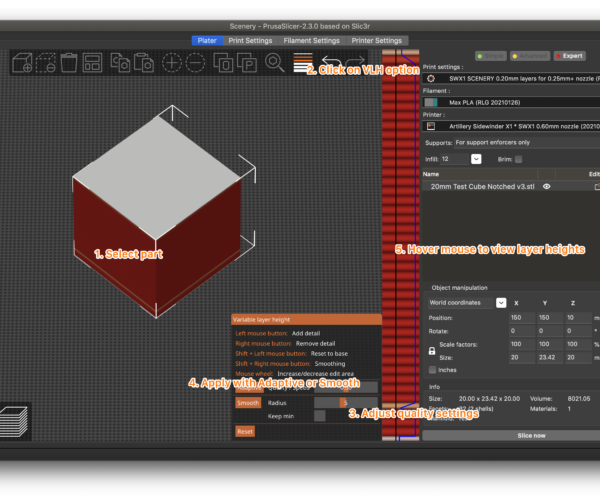

Here's a quick overview:

Steps are as follows:

- Select the part you want to apply VLH to. All instances of the same part will use the same VLH settings, but you must select each separate part individually and apply VLH. Note that each part can have different VLH settings at each layer.

- With the desired part highlighted, click the Variable Layer Height button at the top of the screen.

- In the Variable Layer Height options box, adjust the quality/speed or smoothing radius as desired. Play with these to see what impact it has. Adaptive will optimize each layer independently, Smooth will transition heights gradually between ranges.

- Apply either Adaptive or Smooth to apply the VLH algorithm.

- Observe the resulting range of layer heights applied in the vertical bar at the right. Layer heights will vary between the minimum and maximum layer heights identified under Printer Settings->Extruder 1->Layer height limits.

Make sure that your selected extrusion widths are wider than your maximum layer height to ensure a good oval/stadium cross-section on extrusions for the best inter-layer adhesion. Your extrusion widths can vary between 100-200% of nozzle size, though 120% is a good safe number.

Most of all, experiment. What looks good enough for one user may be far too rough for another.

Have fun with it!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: can I print faster

Just for sh*ts and giggles, I just tried slicing a cube which was about as large as I could get in PS without turning blue.

Normal settings I use, .2mm layers, 15% infill.

It would take 5 days and 6 hours to print.

That's probably close to the upper bound of the longest print that can be done on this machine.

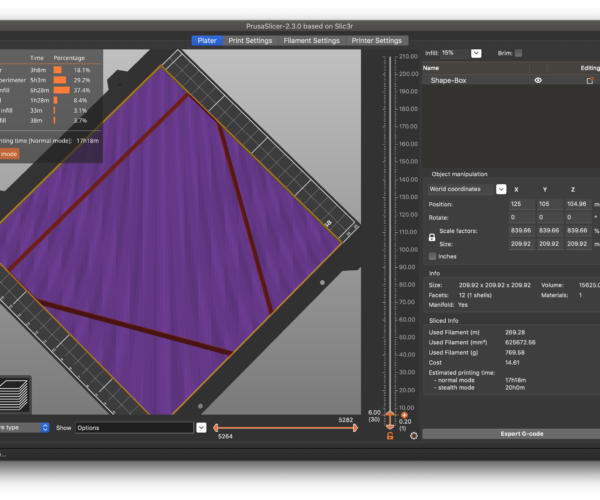

Ah, that's actually an excellent test of the various optimizations! An extreme case, but it sure highlights what different features do. Here's what I got with a cube selected with Scale to print volume.

- Using a 0.4mm nozzle with Prusa default 0.15mm print settings, generic PLA, and a basic Mk3S profile, a 209.92mm^3 print is estimated to take 5d2h17m (1476m). PrusaSlicer would never show the sliced result and got very, very slow.

- Simply changing the infill pattern from the default gyroid pattern to support cubic reduced the estimate to 16h1m (961m). This is a great demonstration of that infill pattern's utility!

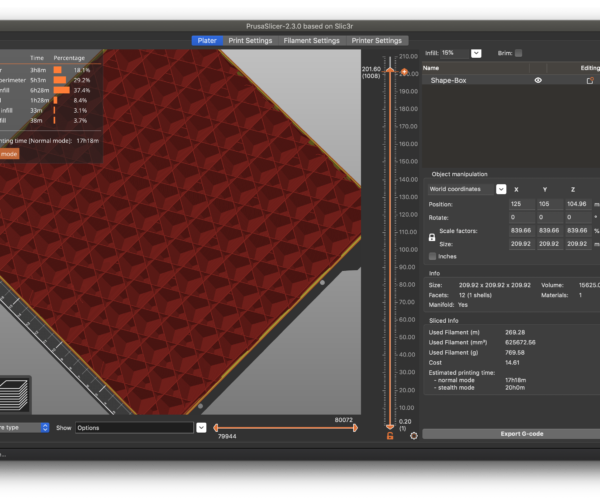

- Switching over to a more practical 0.6mm nozzle profile at 0.2mm layer height, high-throughput PETG profile, support cubic infill pattern, and tweaked printer settings, the time estimate bumped back up to 17h18m (1038m).

- Enabling variable layer height on the cube with the same settings dropped the time estimate to 9h41m (581m).

Now it's not too often that I need a 210mm cube, but these extremes really do highlight the benefit of combining different techniques to make an impractical print something that might be realistic.

I'd never really played with the (new) Support Cubic infill option. It's really great for big, empty prints. Here's what the support structure looks like at the bottom of the 210mm cube print:

And here's the support at the top of the print:

The big print really shows Adaptive Cubic's advantage:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: can I print faster

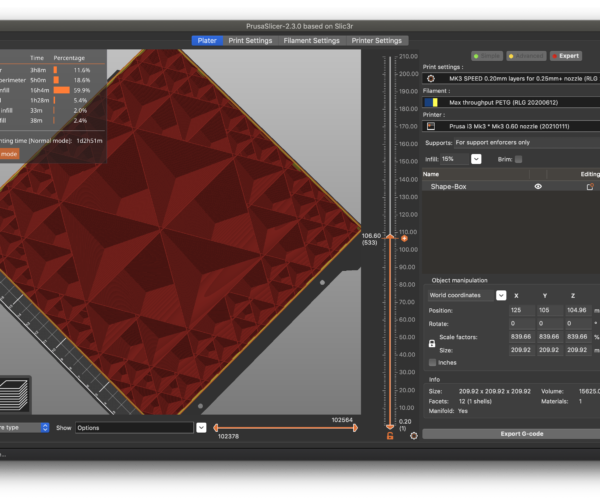

Another example of finding the right settings to optimize production while maintaining quality. This time, I sliced the cube with the optimized 0.6mm nozzle settings, but wanted to show how one can maintain exterior quality while still reducing print times. I tweaked my settings as follows:

- Maximum layer height for my extruder (nozzle) settings to 0.24mm.

- Applied VLH (all layers set to 0.24mm).

- Set infill to Combine infill every 2 layers. At 0.24mm layer height, 2 layers will result in an extrusion height of 0.48mm, ideal to stay at or below 80% of nozzle size.

With these settings, the estimated print time is 13h13m (793m), a marked improvement over the original 5d2h17m (CORRECTION: 7337m). The pic below illustrates the 0.24mm wall layer heights with 0.48mm infill layer heights:

The larger nozzle allows combining more infill layers, even if still printing at relatively low layer heights.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: can I print faster

The larger nozzle allows combining more infill layers, even if still printing at relatively low layer heights.

Again a great learning - an option I never thought about!

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: can I print faster

@bobstro

I would like to add a little levity here.......................you have given me more information then the remainder of my life span ( age 73) can absorb. It's humbling to realize how little one knows about things. You are correct in your assumption that I am in need of a robust, structural part. Detail & finish is the least of my concerns. This is an internal part, no one will see it. I hope I can follow your suggested settings, I hope the program is intuitive. Otherwise you will be hearing from me more than you'd like 😱

Thank You

RE: can I print faster

I'm glad the discussion is thought-provoking. This was a learning exercise for me as well. Have fun with it!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: can I print faster

@jerry-s

Learning can keep your mind fresh - it is research proven.

--------------------

Chuck H

3D Printer Review Blog