Brass nozzle wear

Assuming that non-abrasive materials i.e. PLA/PETG are primarily used, what is the mean time/length before nozzle changes?

RE: Brass nozzle wear

That also depends on the "non-abrasive" material you are using. Even different colours of the same material can show different levels of abrasiveness. From what I know many white filaments for example tend to substantially more abrasive than others (less than metal infill etc however). I would also assume that it also depends if you have a high quality or a cheap brass nozzle. The former might be the same material as the latter but often has greater margins for degradation where it still prints fine.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Brass nozzle wear

Assuming that non-abrasive materials i.e. PLA/PETG are primarily used, what is the mean time/length before nozzle changes?

I change after about 3000 hours - but different filaments wear the nozzle at different rates.

Cheerio,

RE: Brass nozzle wear

I am on my 6th nozzle after 7450m of filament and 178d 19h, printing nothing but PLA. Some of them were changed because of a clog instead of nozzle wear.

They are considered to be consumable and generic nozzles are really cheap.

Steve

RE: Brass nozzle wear

@steve-16

generic nozzles are really cheap.

Just be aware that some generic nozzles have short threads and do not seat properly.

Cheerio,

RE: Brass nozzle wear

@steve-16

generic nozzles are really cheap.

Just be aware that some generic nozzles have short threads and do not seat properly.

Cheerio,

Thanks for the heads up. I have been lucky so far with a set of 15 for around US$10 from Amazon.

RE: Brass nozzle wear

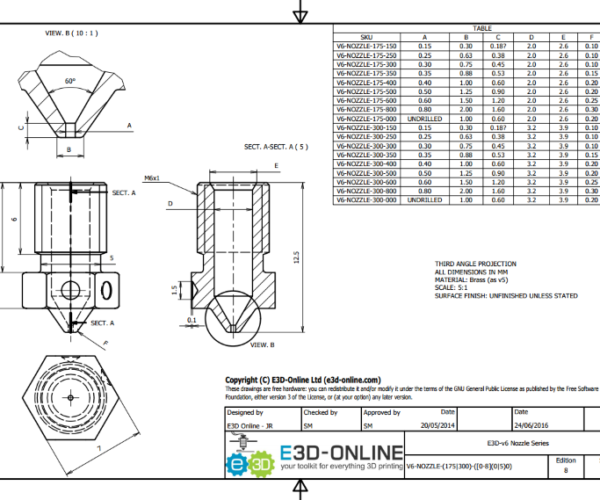

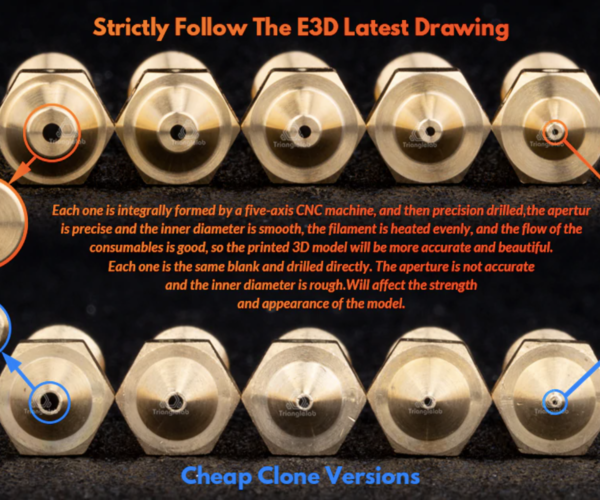

Just be aware that many of the cheaper nozzles use substandard brass. I've seen a few pics taken that show them shearing off easily after printing with higher temps. They are also often not cut to E3D specs, so print quality may suffer. The following pic from TriangleLab (a good quality clone nozzle) shows the difference in the collar around the nozzle opening (the B dimension in the E3D drawing).

The surrounding area should be about 2X the nozzle opening size to give good squish and adhesion with underlying layers, particularly if you use wider extrusions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…