RE: Anyone try Diamondback nozzles?

I don't have experience with a the tungsten carbide nozzle. But just wanted to add this video about a grinder vs nozzles. Tungsten is second best but the Diamondback wins hands down.

Also the Diamond back nozzle is okay with hitting the print bed. I asked this on the Kickstarter. The reply was hitting the print bed was okay. But the nozzle was not intended for smashing the nozzle with a hammer or something like that.

RE: Anyone try Diamondback nozzles?

Interesting nozzle test.

--------------------

Chuck H

3D Printer Review Blog

RE: Anyone try Diamondback nozzles?

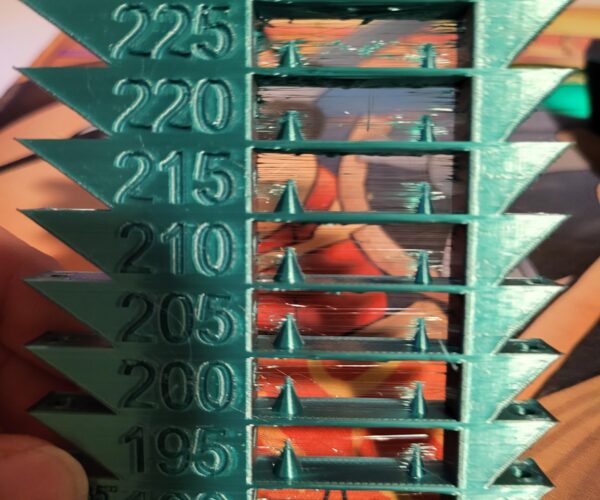

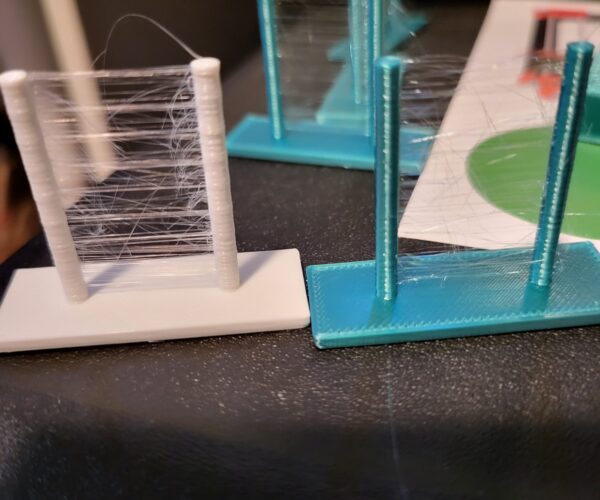

I've also had serious stringing/oozing issues with my MK3S+ since installing a .4mm Diamondback nozzle. Prior to the install printer worked perfectly with default settings. I've ran temp tower tests and even reducing the temp to 190 which seems to have the least amount of stringing issues however my prints look like they are encased in webs. Did a retraction speed calibration test and the results were unreadable due to the severity of stringing. Currently testing to see if my flow rate is over extruding due to the reduced coefficient of friction otherwise I am at a loss on how to salvage my sanity besides going back to a regular copper nozzle. Anyone happen to have setting suggestions or tests I may not have tried yet?

RE: Anyone try Diamondback nozzles?

The diamondback seems to handle lower hotend temperatures just fine so unless you have other reasons not to, I would reduce it -5 to -10°C compared to stock settings. Looking at your temp tower that did also help somewhat. Other than that, how does a properly dried filament look like? Is it also stringing?

Some filaments just tend to string more than others. The diamondback might be slightly more prone to stringing but certainly can print just fine if you are using the right filament.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Anyone try Diamondback nozzles?

I would reduce your default temperature like 15-20 degrees. And then do a new retraction test when possible. Do you have this issue with multiple fillaments?

RE: Anyone try Diamondback nozzles?

If the filament you are using has a temp range starting at 190 I would try 180. In my experience with this nozzle you have to go below the recommended range.

RE: Anyone try Diamondback nozzles?

I tried going at lower temps for the retraction test but still ended up with pretty bad stringing. Can't really push it lower than 175 before the layers suffer. Tried a bunch of retraction speeds/settings but couldn't get better than default settings at 190. Tried multiple filaments with the same result and even opened a new box of Hatchbox white which was still sealed to see if it was a moisture issue but still got same results.

Ended up switching out to a stainless steel which I've had better luck with on my ender. Thinking I got either a rare bad run or I messed up on installing it somehow. Pic below of my retraction tests at 190 and 180.

RE: Anyone try Diamondback nozzles?

I have the 0.4 and the 0.6 Diamondback nozzles and I can't get either to print very well. I'm using Overture PLA which prints very well with my brass nozzles. The extrusion seems good when I look at the top of my prints but the sides are not very smooth/even. I've adjusted the extrusion multiplier to these settings: 1, 98, 95, 92, 90 without success. I've printed from 190-215 degrees without any real difference in the print quality. I've recalibrated the XYZ settings and first layer settings. Wondering what settings people are using that are producing the desired results. I've used both the generic PLA and Prusa filament presets. I'm new to 3d printing so maybe I've missed something in my setup. Thanks.

RE: Anyone try Diamondback nozzles?

I just got a .6mm unit and am pleased with it so far. Just a couple of minutes to swap out the nozzle.

PLA: 5 degrees lower, PET-G 15 degrees lower, these seem to work for me.

You know how sometime the filament "curls" a bit at the tip of the nozzle when changing filament? Now it extrudes straight down... it seems the belief that the diamond may be more slippery might be correct.

I am fiddling with the print speeds, to see if it can be bumped up a bit as well

RE: Anyone try Diamondback nozzles?

I recently ordered a US$49 tungsten to replace one where I broke off a cleaning bit and could not get it out.

RE: Anyone try Diamondback nozzle?

Zack Freedman did a quick review of them has good things to say. I'm interested in what the community finds out about them.

RE: Anyone try Diamondback nozzles?

I most definitely have fitted the nozzle correctly… I can get okay results with my first layer, but it’s spotty. I’ve read that changing the gcode keeps the the nozzle from ozzing out. ( it’s not ozzing out the sides but thru where the filament comes out normally, changed the starting temp lower and had some success with keeping it from doing it.) as far as the under extrusion issue, I now believe it’s actually just getting the first layer to stick to the build plate. Not sure why it would change from a normal nozzle to these but it does. I have 5 different diamond back nozzles and 5 different printers. I’ve tried them and all and they all have the same problems. It really may be that they are great for filament other than PETG and PLA. I will continue to try things out and actually try abrasive filament and see if it’s different.

Have you found a resolution to your problem of the filament not sticking to the build plate with these nozzles? I just changed over to Diamondback after using brass with all 3 build plate types for 18 months without issues. Now I can't get the first layer to stick on any plate. The ends of the lines are curling up. Even after dealing in the live-z calibration, it seems to change and curl again. Very frustrating. I have spent hours trying to fix this with no success.

RE: Anyone try Diamondback nozzles?

I most definitely have fitted the nozzle correctly… I can get okay results with my first layer, but it’s spotty. I’ve read that changing the gcode keeps the the nozzle from ozzing out. ( it’s not ozzing out the sides but thru where the filament comes out normally, changed the starting temp lower and had some success with keeping it from doing it.) as far as the under extrusion issue, I now believe it’s actually just getting the first layer to stick to the build plate. Not sure why it would change from a normal nozzle to these but it does. I have 5 different diamond back nozzles and 5 different printers. I’ve tried them and all and they all have the same problems. It really may be that they are great for filament other than PETG and PLA. I will continue to try things out and actually try abrasive filament and see if it’s different.

Have you found a resolution to your problem of the filament not sticking to the build plate with these nozzles? I just changed over to Diamondback after using brass with all 3 build plate types for 18 months without issues. Now I can't get the first layer to stick on any plate. The ends of the lines are curling up. Even after dealing in the live-z calibration, it seems to change and curl again. Very frustrating. I have spent hours trying to fix this with no success.

@andruskj I'm in the same boat. I've had my MKS3+ for 2 years, perfect prints with PLA/PETG on the OEM nozzle. I decided to replace the nozzle with a Diamondback .4 m. I can't get anything to stick to any build plates, even using a glue stick (which I've only used as a release agent before). I'm about to call it a loss and switch back to brass or Nozzel X.

RE:

Anyone having issues with sticking, try to following:

- The diamond nozzle is a different length than stock. Ensure you have reset your Live-Z calibration per build sheet.

- Wash all your builds beets with dawn dish soap and warm water.

- only clean the build plates with isopropyl alcohol.

I have had the diamondback 0.4mm nozzle for over a year now. No issues with PLA on the smooth sheet and PETG on the textured sheet. Have run glow pla and carbon filled PETG as abrasives through it and the nozzle has been exceptional.

RE: Anyone try Diamondback nozzles?

I most definitely have fitted the nozzle correctly… I can get okay results with my first layer, but it’s spotty. I’ve read that changing the gcode keeps the the nozzle from ozzing out. ( it’s not ozzing out the sides but thru where the filament comes out normally, changed the starting temp lower and had some success with keeping it from doing it.) as far as the under extrusion issue, I now believe it’s actually just getting the first layer to stick to the build plate. Not sure why it would change from a normal nozzle to these but it does. I have 5 different diamond back nozzles and 5 different printers. I’ve tried them and all and they all have the same problems. It really may be that they are great for filament other than PETG and PLA. I will continue to try things out and actually try abrasive filament and see if it’s different.

Have you found a resolution to your problem of the filament not sticking to the build plate with these nozzles? I just changed over to Diamondback after using brass with all 3 build plate types for 18 months without issues. Now I can't get the first layer to stick on any plate. The ends of the lines are curling up. Even after dealing in the live-z calibration, it seems to change and curl again. Very frustrating. I have spent hours trying to fix this with no success.

@andruskj I'm in the same boat. I've had my MKS3+ for 2 years, perfect prints with PLA/PETG on the OEM nozzle. I decided to replace the nozzle with a Diamondback .4 m. I can't get anything to stick to any build plates, even using a glue stick (which I've only used as a release agent before). I'm about to call it a loss and switch back to brass or Nozzel X.

@airlinejoe Thanks for the reply. It has been 3 days since I sent the company an email as suggested above and no reply yet. I tried Prusa tech support. They think the nozzle was too high. Got it fixed but the next print, it curled again. I ran live-z again and the value had changed. Steel sheet was cleaned with dish soap and IPA. I will try their FB group and if it still can’t be fixed, they are going back.

RE: Anyone try Diamondback nozzles?

I most definitely have fitted the nozzle correctly… I can get okay results with my first layer, but it’s spotty. I’ve read that changing the gcode keeps the the nozzle from ozzing out. ( it’s not ozzing out the sides but thru where the filament comes out normally, changed the starting temp lower and had some success with keeping it from doing it.) as far as the under extrusion issue, I now believe it’s actually just getting the first layer to stick to the build plate. Not sure why it would change from a normal nozzle to these but it does. I have 5 different diamond back nozzles and 5 different printers. I’ve tried them and all and they all have the same problems. It really may be that they are great for filament other than PETG and PLA. I will continue to try things out and actually try abrasive filament and see if it’s different.

Have you found a resolution to your problem of the filament not sticking to the build plate with these nozzles? I just changed over to Diamondback after using brass with all 3 build plate types for 18 months without issues. Now I can't get the first layer to stick on any plate. The ends of the lines are curling up. Even after dealing in the live-z calibration, it seems to change and curl again. Very frustrating. I have spent hours trying to fix this with no success.

@andruskj I'm in the same boat. I've had my MKS3+ for 2 years, perfect prints with PLA/PETG on the OEM nozzle. I decided to replace the nozzle with a Diamondback .4 m. I can't get anything to stick to any build plates, even using a glue stick (which I've only used as a release agent before). I'm about to call it a loss and switch back to brass or Nozzel X.

@airlinejoe Thanks for the reply. It has been 3 days since I sent the company an email as suggested above and no reply yet. I tried Prusa tech support. They think the nozzle was too high. Got it fixed but the next print, it curled again. I ran live-z again and the value had changed. Steel sheet was cleaned with dish soap and IPA. I will try their FB group and if it still can’t be fixed, they are going back.

I was finally able to dial mine in. My live-z calibration went from -1.378 to -1.727. I also dropped the nozzle temp by 20 for PETG. Wow what a difference the nozzle actually makes. Thanks for the suggestions everyone.

RE: Anyone try Diamondback nozzles?

Grabbed a revo diamondback for my MK3.5 as I wanted to try some CF filaments... my word, this thing is exceptional. I changed it at the same time I changed my revo heater (got one of the early crap ones), replaced under warranty, it printed PETG-CF pretty much perfect first time. I couldn't even break the strength tab on my test model, insanely good layer adhesion.

As others have found, it conducts heat too well, had to reduce some of the temps of my filament profiles by 5-10 degrees to stop oozing, stringing etc. I may have to keep tweaking, as it does still 'feel' a bit hot. Apart from that, my surfaces look amazing, to get a nice surface finish, I do 'poor mans ironing', where I set the top two layers to 0.42 and reduce the acceleration. Get almost a mirror finish in much less time than standard ironing.

I do have some curl/blobbing, but I am using a new filament on some test models, feels like it's got a lot more G than my usual PETG. I think I'll have to calibrate for it, but haven't bothered as it's only for a few test models. I feel if I reduce the extrusion and temp a little it'll improve, or maybe the retract... dunno. Not going to venture down that rabbit hole as my go to filament (eSun PETG) prints amazingly.

Overall, amazing product, I was going to run the CF through my obxidian, but decided to treat my self. I'm sure it would have handled it fine, but reading about the thermal properties of the diamondback, and lifelong use, I thought why not.

I do have one issue, about the revo's in general... MAKE A FULL SOCK! Seriously, I'm sick of cleaning my nozzle. I'm about to make my own, but far out, why should I need to. This seems like a no brainer.

RE: Anyone try Diamondback nozzles?

Made this, sick of cleaning it;

https://www.printables.com/model/948501-e3d-revo-sock-mould-cast-in-place

RE: Anyone try Diamondback nozzles?

Interesting topic.

After reading again the whole thread. my five cents in the matter are that these nozzles look near perfect, with one drawback: increased oozing and stringing. Lowering the temperature 5-10 degrees seems the answer, but I don’t think that the superior heat transfer of diamond plays a significant role here, That could be the case if the whole nozzle was made of diamond. Being only the small tip, the difference in real temperature of the filament, using diamondback vs copper/brass nozzles must be negligible, I think that the reason of the increased stringing resides on the exceptional low friction coefficient of diamond. At the same temperature, molten filament tends to slip down at a higher rate than with metal or TC nozzles. Therefore, lowering some degrees the temperature fixes quite well the stringing issue .. at the cost of worse interlayer adhesion. There’s no free lunch.

IMHO nozzles made totally of TC are the best compromise, considering price, lifespan and all the other factors involved.

RE: Anyone try Diamondback nozzles?

Diamondback Nozzles in my MK4 for a year. Working well. You can lower temp by 5-10c lower, but I often run without adjusting temp. ASA, PETG and PLA working well. I use normal procedures for keeping tip clean, filament in good shape and sheet adhearing well.

Startup oozing problems eliminated when I installed the MMU3. Z set is done with no filament loaded. Filament is unloaded at the end of a print.