Annealing PLA to make it heat resistant

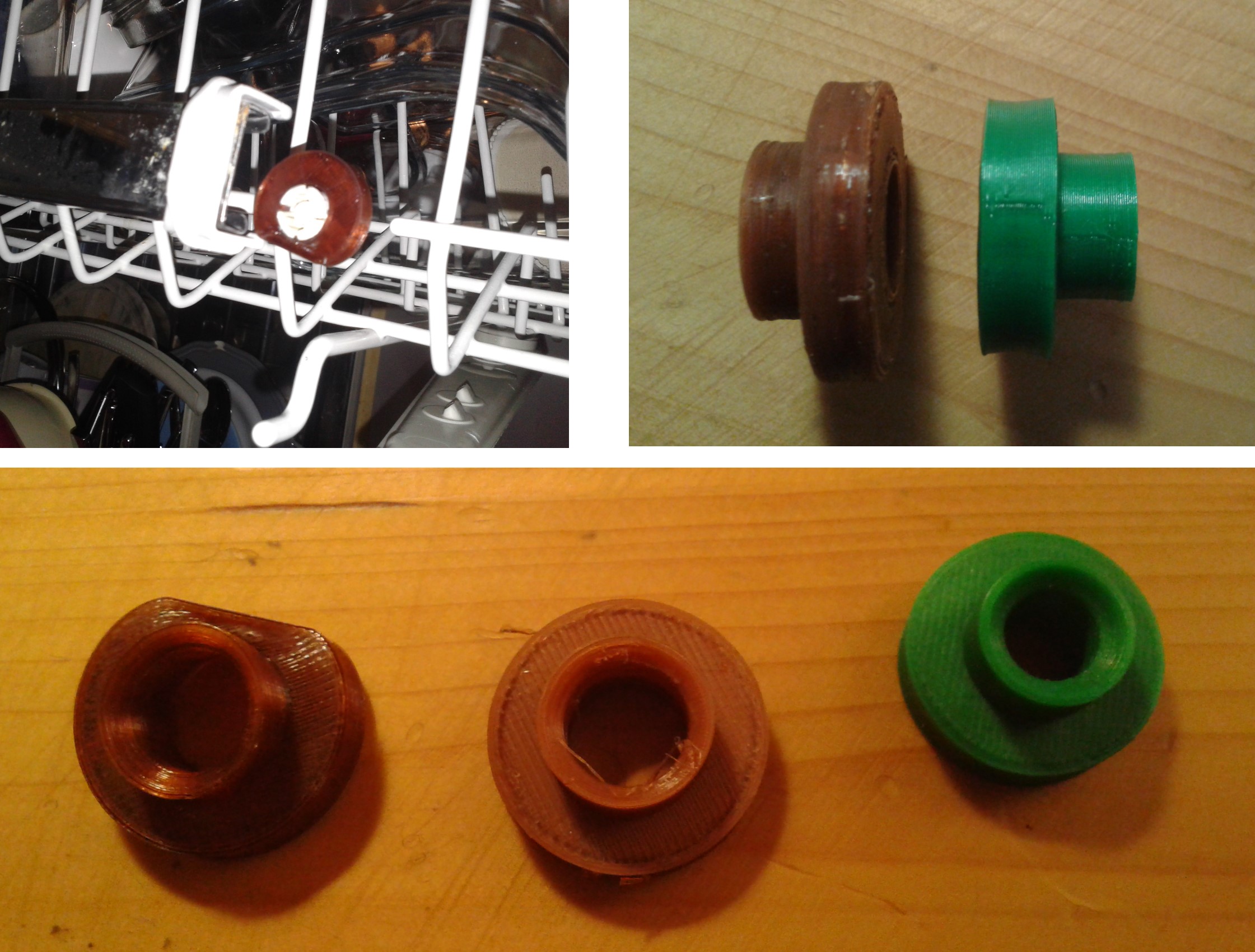

Since the rollers in my dishwasher were broken I wanted to replace them.

I found those two videos which where taking about annealing special HTPLA but also normal PLA to make is heat resistant

I tried to anneal the a green Prusa PLA roller, but it shrunk and warped too much to be usable

Then I printed it with brown Pursa PETG instead, but it did not survive in the dishwasher.

I bought PrimaSelect HTPLA . Annealing work perfect, no shrinkage or warping.

I also testet a few standard PLAs, and found that the black Verbatim PLA had only 3% shrinkage in the xy-Plane, so I scaled it to 103% in slic3r and also annealed it. The result where also quite good.

And both survived the dishwasher, maybe the color changed a bit.

Re: Annealing PLA to make it heat resistant

It'll be interesting to hear back later on how well the HTPLA stood up to the job?

I printed a tea bag tray from plain white PLA and within a week is had stained 'tea coloured', warped horribly and 'puffed up' where I assume the PLA had absorbed loads of moisture.

Keep us updated if you can!

Re: Annealing PLA to make it heat resistant

I'm impressed even HTPLA is working in a dishwasher, due to water environment. Yes please do keep us posted.

My first thought is a good application for a PETG part. Anyone have experience with PETG in a dishwasher (or other hot/wet) environment?

I'm considering a rack accessory (replacing a broken clip) for my dishwasher. Does PETG hold up?

Re: Annealing PLA to make it heat resistant

The lifetime of my dishwasher ended because it was leaking through a hole made out of rust.

As a consequence my tests ended.

My final results form this dishwasher are:

PETG -> failed (in one day)

annealed HTPLA -> ok (testperiod around 70 days)

annealed normal PLA -> ok (testperiod 2 days)

I really would have like to see how normal PLA would have performed over a longer period.

I suspect that there is not the big difference, between normal PLA and HTPLA, except for the price.

Re: Annealing PLA to make it heat resistant

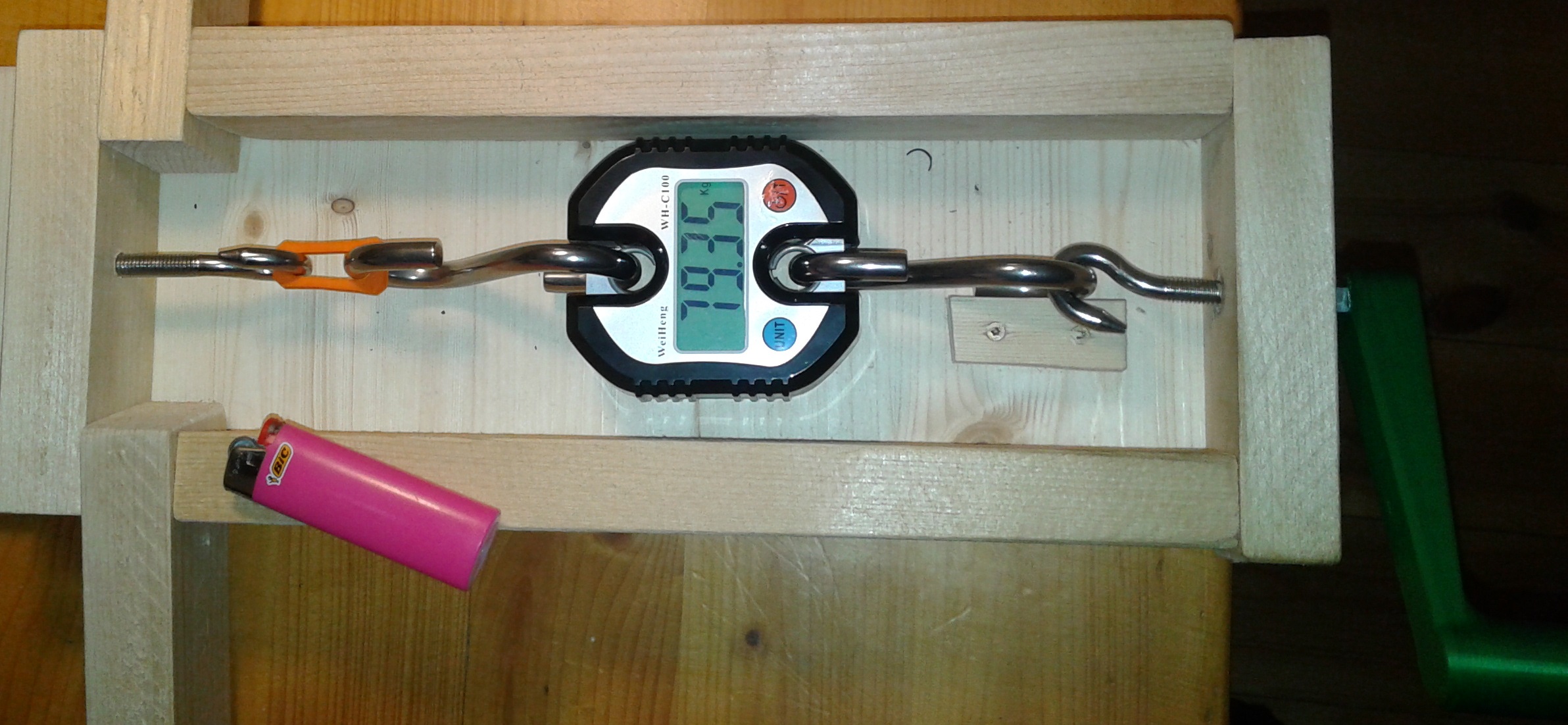

I build a strength testing machine, and tested different materials for their strength.

I find it amazing that such a tiny 3d printed chain link can hold 75kg.

I heated those chain links in the oven, to a certain temperature and tested them quickly (to prevent cooling) for their strength.

I used orange ICE PLA , brown Prusa PTEG, and blue Verbatim PLA (annealed)

The results:

I entered minus one ( -1 ) into the table wenn the material got so soft (nearly liquid) that it could not hold its form when taking it out of the oven.

Re: Annealing PLA to make it heat resistant

I printed a pair of tweezers, and tried to

use the heated print bed to anneal the PLA in place

So directly after printing I cranked the temperature up to 112C for 10 minutes and placed a sheet of paper over it.

It work quite good. It realeased from the flex pint platte even better after cooling then untreated prints.

I got some very subtile angles here and there, but the deviations are minor. I assume if I had used bit of elephantfoot compensation, it would have be just perfect.

I got the Idea from here: