3D printing gears

Hi All,

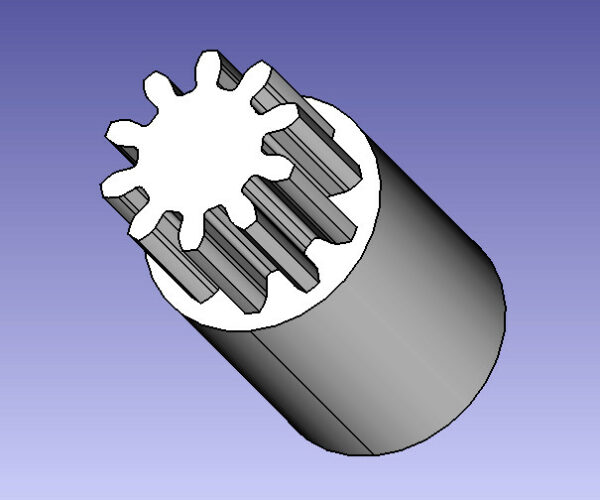

I'm working on a project that needs some 3D printed gears to transfer the drive from a couple of stepper motors.

One drives a 4:1 reduction gearbox with 2 spur gears while the other is a worm drive.

I'm initially going to print them in PETG but I'm open to suggestions

Does anyone have any experience in printing gears and what sort of life I can expect ?

I'd also be interested in whether ASA or Nylon would be a better choice

Thanks

Best Answer by 3DALHEMIJA:

You should consider buying IGUS iglidur wear-resistant filament - dedicated for gears and such applications.

RE: 3D printing gears

I would not use PETG for gears - my choice would be PLA if temperature is no issue or better ABS. Nylon is also a good choice, but it is not that easy to print.

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: 3D printing gears

I would not use PETG for gears - my choice would be PLA if temperature is no issue or better ABS. Nylon is also a good choice, but it is not that easy to print.

Best regards, Clemens

I curious why you would use PLA in preference to PETG?

RE: 3D printing gears

@clemens-m

Hi Clemens,

Thanks for your reply

I'm using the gears in an application that is outside in an enclosure and is subject to humidity ( ~70% ) and high temperature ( ~35degC ) hence I didn't think PLA would be a good choice.

From your comments I will probably go for Nylon or ABS

thanks again !

Peter

RE: 3D printing gears

You should consider buying IGUS iglidur wear-resistant filament - dedicated for gears and such applications.

RE: 3D printing gears

Believe it or not, I've had good luck printing small gears in PLA.

I also agree that in general, ABS or better yet the newer PC Blend would probably be better.

RE: 3D printing gears

I don't use PLA myself but I see no reason why your requirment (high humidity and ~35degC ) would be a problem for PLA although I suppose the "outside" might be an issue as I believe the PLA is not UV stabilized.

RE: 3D printing gears

@towlerg

thanks for the reply , I'm going to be testing it over the winter outside (Northern UK) so I will soon know what works.

Most of the parts will be inside a UPVC tubeand so won't be subjected to UV

I just need my Mini to arrive !

RE: 3D printing gears

You should consider buying IGUS iglidur wear-resistant filament - dedicated for gears and such applications.

I didn't know that existed !

They have a big range .... but they aren't cheap .... still it might be suitable for a couple of parts I need

Thanks !

RE: 3D printing gears

@thermaldesignconsultants

I have printed some gears for the car racing sports and can recommend the following materials:

Nylon PA6.6

Iglidur I180

ASA DuraPro

Nylon is a bit more difficult to print, but very stable. ASA DuraPro, easy to print, is weather and UV resistant, less warping than ABS and good layer adhesion.

Iglidur I180, easy to print, is good for wet areas and has excellent gliding properties.

Asa is the cheapest material in terms of price.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: 3D printing gears

@karl-herbert

Thanks for the info Karl .... looks like I've got some testing to do !!

Regards

Peter

RE: 3D printing gears

PLA for gears is perfectly fine for the first version. You just need to make sure they are not getting hot (<50C ) especially during operation.

If your first PLA version breaks, I would suggest to check first why it broke and how. Maybe adjust your design, if it broke because of mechanical stress. Once there are no options for design changes, I would print with Nylon next.

Try to avoid any PC blends as it makes the part brittle. PC is not good for steady varying mechanical stress.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: 3D printing gears

@nikolai-r

@thermaldesignconsultants

"Try to avoid any PC blends as it makes the part brittle. PC is not good for steady varying mechanical stress."

From experience I agree with this 100%!!

PC alloys become brittle and fragile within a short time.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: 3D printing gears

@karl-herbert

Dear Karl,

Are you willing to share your (prusa slicer) settings for Iglidur I150 ?

Cheers, Bas

RE: 3D printing gears

@bas

If you would send me a sample STL file, I can slice it with my profile and upload the 3mf. I printed I180 with it, but it shouldn't be a big difference to I150 in terms of printing parameters. Some fine adjustment is always necessary.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: 3D printing gears

Definitely avoid PETG.

PLA is surprisingly good for gearing, especially if printed large with accurate involutes (reduce friction heating) and perhaps some PTFE lubrication.

I suggest you use cheap PLA for prototyping and only move to Nylon if needed at the last stage.

Cheerio,

RE: 3D printing gears

PLA is surprisingly good for gearing, especially if printed large with accurate involutes (reduce friction heating) and perhaps some PTFE lubrication.

I suggest you use cheap PLA for prototyping and only move to Nylon if needed at the last stage.

I'm following this thread with some interest, as I've done a few geared projects but never one involving transmission of any significant amount of power. I've used both my own gears (developed with the 'involute gear wizard' in FreeCAD) and some gears downloaded from the usual suspect sites.

The choice of material for gears is something that I don't have a feel for yet. So far, all of my geared projects have been PLA.

My first self-designed geared project has now been operating for over six months, used daily, and is in what I might call a hostile damp environment, as in a toilet tank. I've discussed the project here before, but one thing I've always been leery of is how well the gears, particularly the smaller driving gear, would hold up. I honestly expected it to break down and strip months ago. Had it done that, I was intending to reprint it in ABS and, after I discovered PC Blend, in PC Blend, for the added strength.

I think of PLA as being biodegradable, as in more likely to break down in warm damp environments, and hydrophillic, as in likely to absorb H2O from the air and weaken. Fortunately the project has not self-destructed (yet) and is regularly used several times per day. The gears are shown below, but you have to look closely at the IRL shot.

RE: 3D printing gears

@jsw

I think of PLA as being biodegradable, as in more likely to break down in warm damp environments, and hydrophillic, as in likely to absorb H2O from the air and weaken.

PLA is biodegradeable, slowly in most cases, relatively quickly in certain environments.

PLA is used as scaffolding in some types of surgery, it degrades as tissues recover and is gone in about two years.

In HOT compost it decomposes at about the same rate. (HOT: steaming heaps, industrial composting.)

UV light does hasten the breakdown, especially in pale/translucent coloured PLA.

In cold and wet circumstances it decomposes VERY slowly, it may last tens of years. Unlike many plastics it does eventually decay so it doesn't add to the long term pollution of the planet but for ordinary human uses it can be treated as just another plastic.

Gearing? Here is one of my 'Lockdown' projects:

Cheerio,

RE: 3D printing gears

@karl-herbert

Dear Karl,

See attached a example stl file of a combined gear. Thank in advance!

Cheers, Bas

ps mmm an stl file is not aloud as attached file. I have to try something else

RE: 3D printing gears

@karl-herbert

Dear Karl,

See the link for an example stl file of a hering-bone-gear. Thank in advance!

https://www.prusaprinters.org/prints/48564-heringbone-gears-4020-for-test-with-igidur-i150-fi

Cheers, Bas