Skidster

I needed another project during vacation and this pandemic crap. I decided to design and build a skipster (Bobcat). I't still in the prototype stage but it's coming along. The wood pieces will probably get replaced out of aluminum and most of the printed pieces will be black. Of course I will be using Prusa filament. I will posting updated pics as work progresses. The model is aprox 24" long from rear to front of bucket and 14" wide at the tracks. It should be able to move snow. I intend on installing the GoPro so I can get a live feed from our living room.

RE: Skidster

If this thing can truly move snow, I may be in line for the "Outdoor Roomba" project myself. To have this thing warm up and zip around the sidewalk and driveway every hour or so overnight would be awesome. Please keep us updated!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Skidster

Very nice. I do not get much snow but put a lawn more blade on it and we are un business.

--------------------

Chuck H

3D Printer Review Blog

RE: Skidster

@skipper_52

Looks like a fun project, I like the tracks, can't wait to see the bucket.

The Filament Whisperer

RE: Skidster

What will you be using to power this thing?

RE: Skidster

@jsw

Have to make a change in design. I'm going to have to print a gear box. 12v power system, buckboard it down to 11.5v for the motors. Battery has to be a motorcycle 12v. I need the amps to have any kind of run time.

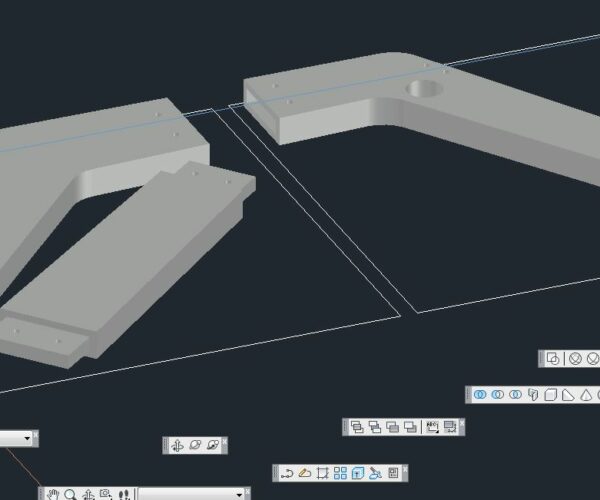

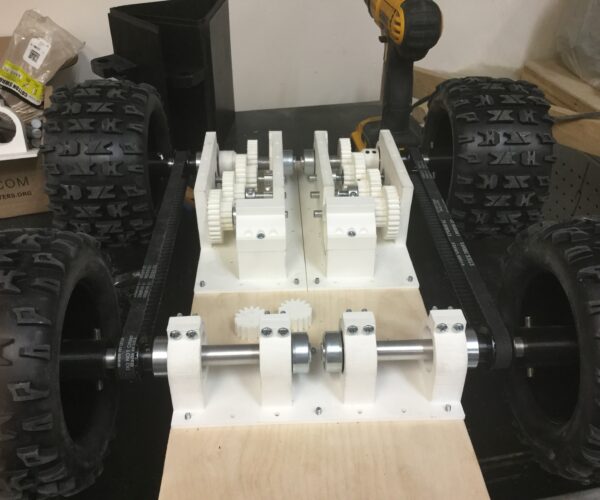

I'm not going to be able to use the tracks like I wanted to and am swapping them out for rc truck tires which actually make it look more like a skidster. It has to be a split shaft drive system (read drive) and I will have (2) speed controllers so I can spin it. I'll keep send pics as I progress. I should be done with the bucket tomorrow sometime. It's been a long print and I had to split it into 4 sections (2 ends) (2 middle). Overall the bucket is 16" long. I am not a "tesla" by any means and unfortunately use the Tom Edison approach a lot. (trial and error).

RE: Skidster

@jsw

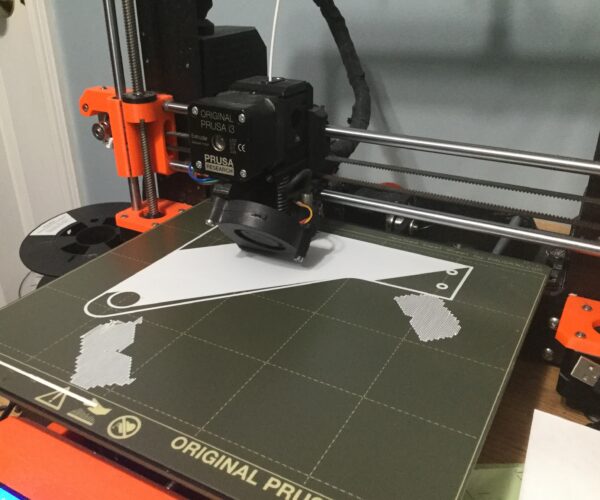

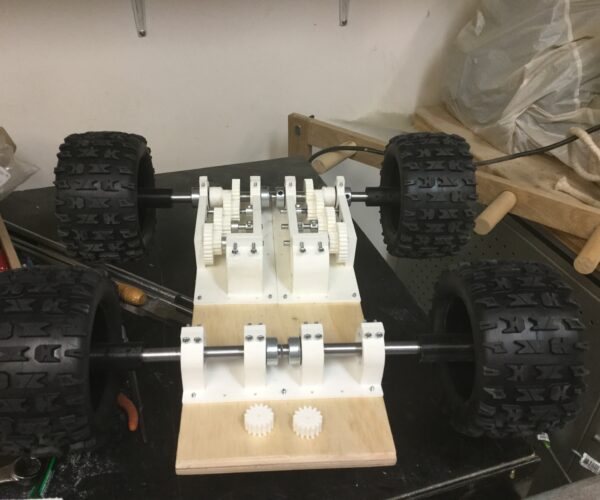

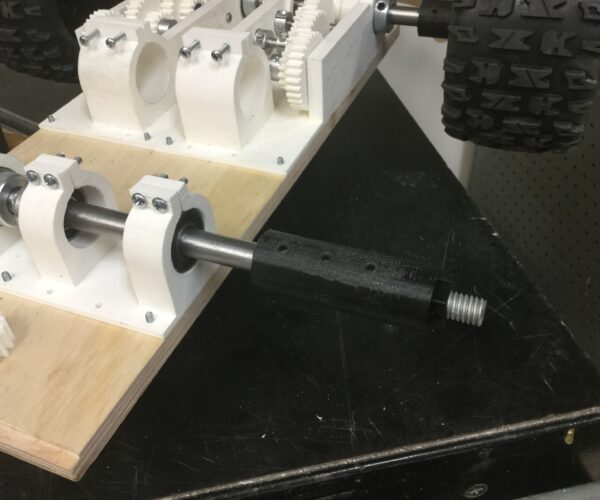

Here's a pic of the gear boxes. Each rear wheel needs to be independently controlled (tank). I've ordered (2) rc truck (crawler) motors. They turn at 1208 rpm at max. The tires are 6" tall. These will allow me a max of aprox 75ft. per min. I am printing the 1st one now to test it.

RE: Skidster

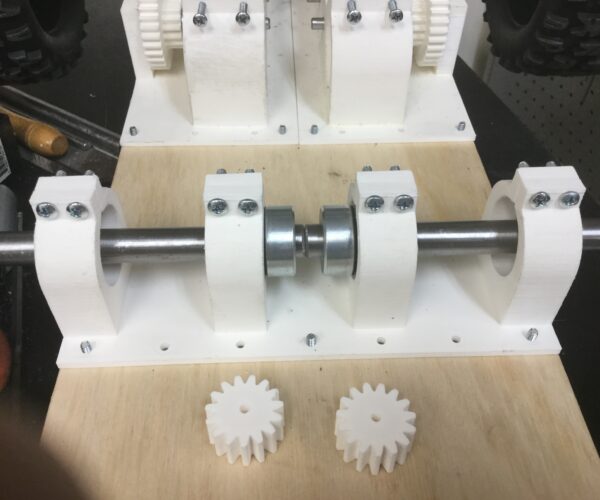

Got one of the gear boxes built. Printing the 2nd one. Got clock gears in it now but there's a lot of growling. Going to try printing a set of machine gears. That should quiet it down. Gear reduction is 75:1. Wheel is 6" tall and 4" wide. Still waiting for the motors to arrive.

RE: Skidster

Got the 2nd gearbox built (printed) and changed the gears from clock to 20 deg spurs. Runs much quieter and smoother. Motors should come today with the 1/2"aluminum axles. Printing the front end pillow block assembly now (10 hrs) and will post that when I get it done.

RE: Skidster

Very interesting project, Skipper. I'm waiting to see if it will indeed be an effective snow removal bot type of thing.

RE: Skidster

RE: Skidster

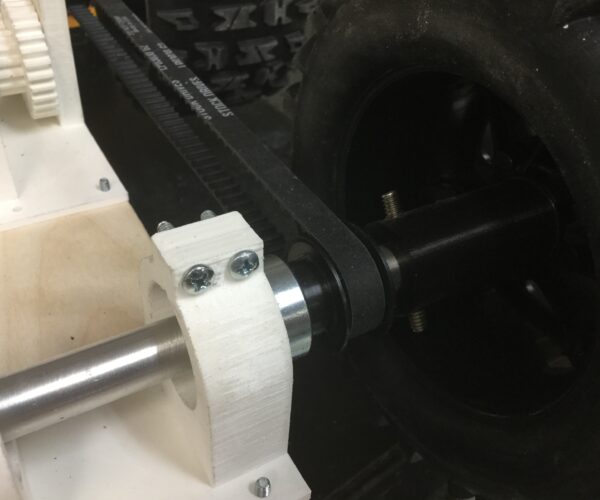

My bud insisted I make it 4 wheel drive. Timing belts and pulleys coming. Will be on the outside of body for easy removal. Will send pics when they get here. For those of you looking for 3d parts (cad,sat, etc) I get mine for designing from McMaster Carr. They have 3d models for just about every part they sell.

RE: Skidster

Out of curiosity, what filament (material) are you printing those gears out of and what infill percentage?

RE: Skidster

@jsw

Everything is PLA from Prusa. I've tried others and haven't been happy.Gears are .15 layer Quality with 25% fill. Spindles are solid at .15. Mounts are 15% fill with .15 layer quality.

RE: Skidster

I'm just thinking of the strength of the gears and the torque at the far end of your gear train. It looks like you have three stages of speed reduction there, and the torque at the axle end will be quite high.

I've never attempted 3d printed gears for such a real-world load yet. The most I've done with gears are things like an automatic flush valve and a model wind turbine. 😉

RE: Skidster

@jsw

Believe it or not they are stronger than hell. I ran it with the test motor at aprox 500 rpm at the back (axle) and applied pressure to the axle. I couldn't stop it. There is this guy on youtube that printed a gear replacement for an atlas lathe and stalled the belts with no damage to the gear. My end speed iwill be aprox 100 ft. per min. The motors are only 2008 rpm. my gears ratio ends up to be 75:1. Wheels are 6" tall.

RE: Skidster

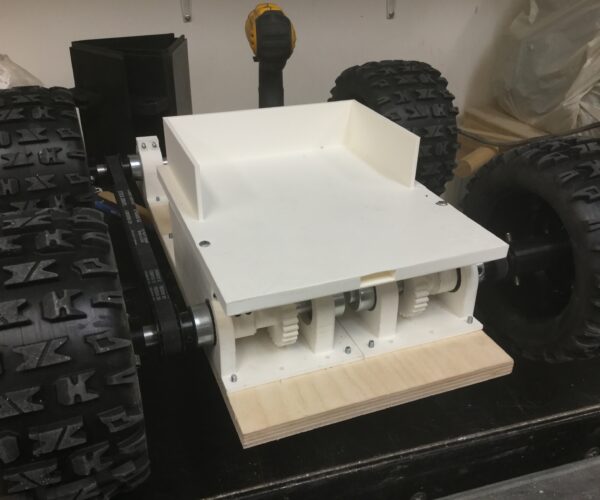

Change to gearboxes. Motors are now replaceable from top by unscrewing caps. Old design required removal of gearbox to change out motors.

4 wheel drive installed. Front wheels now driven from rear axles via belts and timing pulleys.

Closeup of front end drive belts

Battery Tray (note wire chase built into bottom)

On hold now until electronics get here.

RE: Skidster

The bucket arms are quite large. Overall footprint for them is 8" x 19.5". Impossible to print in one piece on my Prusa. I created mortise and tenon joints to join them and will epoxy them together. Prints are taking about 12 hours for each arm. Sure there's some sanding involved when assembled but I'm painting the Skidster anyway so any little imperfections will go away. The PLA arms weight about 1/3 the weight of the plywood ones which will be less stress on the screw actuators.