PrusaSlicer vs Cura

Hello,

I've been using Cura for about 2 years and it has worked well for me - just hobby/gift printing with a few replacement parts every now and then - now that I have a MK3S, are there reasons I should consider switching over to PrusaSlicer - especially with the new upgrade? Appreciate any thoughts or recommendations.

Best Answer by bobstro:

Yes. PrusaSlicer and the Slic3r slicer it's based on support the use of a Maximum volumetric speed setting corresponding to the maximum throughput of your hotend. By using this, you can avoid painful tweaking of print speeds to avoid overrunning the extruder's capacity and the associated extruder clicks, skips and jams. You can set MVS on a per-filament or per-print settings basis and not have to tweak speeds. Set your preferred speeds in your print settings and the slicer will print up to those speeds, but throttle when and only if necessary to maintain an appropriate MVS. Without this, you have to set "worst case" maximums for your speeds which can really slow things down.

I also prefer PS' ability to separate printer, print job and filament settings into individual discrete profiles, which is very handy if you're experimenting a lot with different filaments and nozzle sizes.

Finally, PS is being developed by TeamPrusa, and it is highly optimized for the expensive Prusa printer you spent all that money on. If you want to make the most of the features this printer provides, you're likely to find supporting features in PrusaSlicer first (e.g. remaining print time display).

Cura (at least current releases) is a fine slicer, and has great features if you're doing one-off prints, especially for things like miniatures. I really like Cura, but I always figure things out 1st in PrusaSlicer (formerly Slic3rPE), then translate the settings to other slicers.

RE: PrusaSlicer vs Cura

Yes. PrusaSlicer and the Slic3r slicer it's based on support the use of a Maximum volumetric speed setting corresponding to the maximum throughput of your hotend. By using this, you can avoid painful tweaking of print speeds to avoid overrunning the extruder's capacity and the associated extruder clicks, skips and jams. You can set MVS on a per-filament or per-print settings basis and not have to tweak speeds. Set your preferred speeds in your print settings and the slicer will print up to those speeds, but throttle when and only if necessary to maintain an appropriate MVS. Without this, you have to set "worst case" maximums for your speeds which can really slow things down.

I also prefer PS' ability to separate printer, print job and filament settings into individual discrete profiles, which is very handy if you're experimenting a lot with different filaments and nozzle sizes.

Finally, PS is being developed by TeamPrusa, and it is highly optimized for the expensive Prusa printer you spent all that money on. If you want to make the most of the features this printer provides, you're likely to find supporting features in PrusaSlicer first (e.g. remaining print time display).

Cura (at least current releases) is a fine slicer, and has great features if you're doing one-off prints, especially for things like miniatures. I really like Cura, but I always figure things out 1st in PrusaSlicer (formerly Slic3rPE), then translate the settings to other slicers.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PrusaSlicer vs Cura

We would be thankful, if you guys could expand on why Cura is better for printing miniatures and what does Cura better than PrusaSlicer. I know there are tree supports, ironing, the fuzzy skin. I wonder what are the other things people prefer or pick Cura over PrusaSlicer.

RE: PrusaSlicer vs Cura

We would be thankful, if you guys could expand on why Cura is better for printing miniatures and what does Cura better than PrusaSlicer. I know there are tree supports, ironing, the fuzzy skin. I wonder what are the other things people prefer or pick Cura over PrusaSlicer.

I don't do a lot of miniatures, but there are some features in Cura that help with fine detail prints:

- Tree supports. As you note, these can be easier to remove, especially around delicate features.

- Support pattern selection. Concentric supports or other variations can be easier to remove, especially around delicate features.

- Finer control of z-seam location (e.g. sharpest corner) can help with appearance.

- Minimum layer print time cooling. Rather than only slowing down on minimum layer times, Cura provides an option to physically move the nozzle away from the print to avoid melting delicate features such as fingers and horns.

- Automatic variable layer height. This is very useful for miniatures that have a tall even base, but features near the top or bottom that will benefit from lower layer heights. (PrusaSlicer has the basic feature, but it has to be manually applied in a rather odd manner. Just let us select some parameters controlling when and how it is applied.)

KISSlicer has some features TeamPrusa should spend a day with:

- Very fine adjustments to z-seam placement, making it possible to tune them out to a much higher degree. There's a "random spread" that moves the seam about within an arc the user can specify that can result in conical shapes with a not-quite-perfect but very even looking surface that is easy to post-process. Not random over the whole model, but not in a deep linear seam either.

- Modifier to fill density based on SVG pattern. A B&W gradient can be applied, with infill increasing in darker or lighter image areas. Cura is doing something similar with variable infill, allowing less material to be used in the center and more near surfaces.

- KISS' variable layer height is amazing, providing much more control than any other I've seen. It is closely tied to percentage of overlap with adjacent layers, providing very smooth transitions even with fairly coarse layer heights. Another feature that is very handy for miniatures.

- KISS allows layers to vary from model to model even at the same Z-height. This may not be very efficient, but it allows a miniature with a variety of parts, each with different layer heights at different layers, to be printed together.

TeamPrusa should also look at ideaMaker:

- IM provides custom supports as good as Simplify 3D.

- IM allows a filament profile to include over-rides of any other slicer setting, making it very easy to create a solid printer profile, then just modify those parameters for each specific filament (e.g. temps, speeds).

Finally, someone should look at how Affinity is taking on Adobe Photoshop and some of the big players. One of their strengths is the total control they give the designer:

- Every setting is exposed as a variable. PrusaSlicer already does this under the hood, and we can create configs and gcode using placeholders like [nozzle_diameter]. They take it a step further and allow any settings that takes a value to accept either an integer or float, but also formulas. For example, I'd like my layer height to be set as [nozzle_diameter]*0.8. This would cut down on the number of profiles I have to maintain.

It would also be great if each print profile allowed a selection of nozzle sub-configurations to be associated with it. I'd really like to have different settings for coated and hardened nozzles of the same diameter.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PrusaSlicer vs Cura

Thanks bobstro - started using PursaSlicer last night - first model printing now..

RE: PrusaSlicer vs Cura

Thanks bobstro - started using PursaSlicer last night - first model printing now..

There's no reason you can't have both in your toolbox. I view PS as the "Engineer's" slicer. You can get in and tweak settings until you find settings that will give you repeatable results print after print. Cura is more of my "Artist's" slicer, allowing me to get the settings just right for a specific print. I like to figure out all the hard stuff with temps, speeds and general settings in PS, then switch to Cura (or another slicer) for specific needs. Have fun with it!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PrusaSlicer vs Cura

If you don't have MMU/MMU2 unit then you can use any slicer. IMHO "the best slicer" is the one which you know best.

If you get used to Cura and knows how to tweak it for best results then you will get worse results with the defaults settings in another slicer. So my recommendation is if you don't miss any features in Cura and don't want to use any specific feature in PrusaSlicer then stick to Cura. There is no reason to print another 100 benchys to understand the settings of the new slicer.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: PrusaSlicer vs Cura

i'm also looking for go from cura 4.0 to prusaslicer... but tree support (and also conic support) are great....

RE: PrusaSlicer vs Cura

> Tree supports. As you note, these can be easier to remove, especially around delicate features.

I have to look into their algorithm. I searched the Internet and I did not find much information apart from some experimental prints after the Cura release containing this feature. Ultimaker keeps this feature still marked as experimental. I was surprised that the tree supports touch sharp conical tips just at the cone tips, this could not possibly be printable. I will certainly print some though.

> Support pattern selection. Concentric supports or other variations can be easier to remove, especially around delicate features.

Would you please provide Cura projects I can experiment with, where the benefit of concentric supports is visible?

> Finer control of z-seam location (e.g. sharpest corner) can help with appearance.

This was always silently implicitly on in Slic3r / Slic3r PE / PrusaSlicer. It surprises me Cura made such a fuss of it when they implemented it. Slic3r PE / PrusaSlicer tries to fullfill the following constraints: Hide seams on sharp concave or convex corners. Don't start on overhang. If rear seam is selected, try also to put the seam at the rear side of the print. These constraints are often contradictory, so PrusaSlicer may not pick the one the user would wish.

> Very fine adjustments to z-seam placement, making it possible to tune them out to a much higher degree.

We may implement seam painting tool. Maybe in the next release, maybe in the 2nd next release.

> Minimum layer print time cooling. Rather than only slowing down on minimum layer times, Cura provides an option to physically move the nozzle away from the print to avoid melting delicate features such as fingers and horns.

but then the material from the nozzle may leak out causing gaps at the start of the next layer. I know this feature was even in the old Cura. I wonder whether any other slicer implements this feature.

> Automatic variable layer height.

Done.

> KISS allows layers to vary from model to model even at the same Z-height.

Slic3r / Slic3r PE / PrusaSlicer always supported that.

> TeamPrusa should also look at ideaMaker:

> IM provides custom supports as good as Simplify 3D.

I am not convinced that that clickity click supports by S3D and copied by IdeaMaker are that great. Actualy the automatic S3D support generator is pretty blind and S3D would not be usable without manual clickity click. We are working on painting the support blockers / enforcers areas on the triangle mesh.

> IM allows a filament profile to include over-rides of any other slicer setting, making it very easy to create a solid printer profile, then just modify those parameters for each specific filament (e.g. temps, speeds).

We did some of it with the filament retract overrides. We know a full "last word" of the filament profile over other profiles would be nice, though we have to prioritize.

> Every setting is exposed as a variable. PrusaSlicer already does this under the hood, and we can create configs and gcode using placeholders like [nozzle_diameter]. They take it a step further and allow any settings that takes a value to accept either an integer or float, but also formulas. For example, I'd like my layer height to be set as [nozzle_diameter]*0.8. This would cut down on the number of profiles I have to maintain.

That is somehow manageable if these formulas are written just inside the config files. It is much more involved to implement it into the UI. My feeling is the benefits are not worth the effort at least for now compared to the benefits of other requests being implemented.

Now back to the claim that Cura prints miniatures better than PrusaSlicer. My general stance towards these claims is the following: Please provide me possibly with two project files. One for PrusaSlicer and one for the alternate slicer which you claim does the particular job better. Then I can run the prints and compare the results myself. We really need the Cura profiles and Cura projects to be able to reproduce your claims and see the results with our own eyes. If these claims are provable, then we will likely be more motivated to improve in that particular area.

RE: PrusaSlicer vs Cura

> Tree supports. As you note, these can be easier to remove, especially around delicate features.

I have to look into their algorithm. I searched the Internet and I did not find much information apart from some experimental prints after the Cura release containing this feature. Ultimaker keeps this feature still marked as experimental. I was surprised that the tree supports touch sharp conical tips just at the cone tips, this could not possibly be printable. I will certainly print some though.

I am not a big miniatures fan. I am able to get decent results with PrusaSlicer. There are some people getting really amazing results using Cura, but I have to wonder how much post-processing they've done in some of the pics. Since writing my response, I spent more time with PrusaSlicer on miniatures and found I can get by without tree supports. However, for some prints, they are much preferred by those who print miniatures extensively. I'd put these in the "test and see" category. Everybody wants "easier supports" and you guys may hit on a better solution.

> Support pattern selection. Concentric supports or other variations can be easier to remove, especially around delicate features.

Would you please provide Cura projects I can experiment with, where the benefit of concentric supports is visible?

I would suggest using the Paladin and Explorer free demo STLs from Heroforgeas those are what a lot of people start with. The Paladin has the delicate helmet wings, a pointy shield tip and a cape that's a nightmare for supports. The Explorer model has the torch and book that are a challenge, plus the delicate sword handle. Both can print well with PrusaSlicer:

However, those are my results at 0.15mm layer height. A lot of people after miniatures want 0.05mm... although it's debatable whether that really gains much. At some point, a resin printer is what you want.

> Finer control of z-seam location (e.g. sharpest corner) can help with appearance.

This was always silently implicitly on in Slic3r / Slic3r PE / PrusaSlicer. It surprises me Cura made such a fuss of it when they implemented it. Slic3r PE / PrusaSlicer tries to fullfill the following constraints: Hide seams on sharp concave or convex corners. Don't start on overhang. If rear seam is selected, try also to put the seam at the rear side of the print. These constraints are often contradictory, so PrusaSlicer may not pick the one the user would wish.

Your target on this one is KISSlicer. That slicer lets you select an angle (not just "rear") to align the seam, then provides a "fuzz" setting to allow specific seam position for each layer to vary by some degrees. This lets you both hide the seam in corners when possible, yet make it easier to sand on cylindrical or round surfaces. I think a lot of z-seam issues are related to over-extrusion, so this is partially a documentation issue. I can hide the seam pretty well with PrusaSlicer currently with proper calibration:

That 40mm sphere will look a bit worse in silver though.

> Very fine adjustments to z-seam placement, making it possible to tune them out to a much higher degree.

We may implement seam painting tool. Maybe in the next release, maybe in the 2nd next release.

Look at KISSlicer and particularly the pathing used. There are some interesting "tucking" patterns that are worth being aware of.

> Minimum layer print time cooling. Rather than only slowing down on minimum layer times, Cura provides an option to physically move the nozzle away from the print to avoid melting delicate features such as fingers and horns.

but then the material from the nozzle may leak out causing gaps at the start of the next layer. I know this feature was even in the old Cura. I wonder whether any other slicer implements this feature.

True, definitely a trade-off. Things like the tips of swords and torch on the Explorer model are a good test. Anything pointy is a challenge for miniatures.

> Automatic variable layer height.

Done.

> KISS allows layers to vary from model to model even at the same Z-height.

Slic3r / Slic3r PE / PrusaSlicer always supported that.

Yes! It wasn't clear from earlier releases, but you guys blew me away with the recent automatic variable layer height feature and preview mode. Again, I think better documentation will help clear up confusion. I know you guys are working on that right now. This is a big improvement over S3D's "process" feature, at least as I used it. I'm not 100% certain, but I believe variable layers in Cura are applied to an entire layer, not just one specific model on the bed.

> TeamPrusa should also look at ideaMaker:

> IM provides custom supports as good as Simplify 3D.I am not convinced that that clickity click supports by S3D and copied by IdeaMaker are that great. Actualy the automatic S3D support generator is pretty blind and S3D would not be usable without manual clickity click. We are working on painting the support blockers / enforcers areas on the triangle mesh.

I like your mention of "painting". The little bricks aren't ideal, but creating modifiers is a bit ... weird. Especially the resizing (e.g. when I want to reduce the height of a modifier slab and it moves both top and bottom to the center). It would be nice to rotate the model on screen and indicate "support here" right on the model instead of trying to interpret from the base.

> IM allows a filament profile to include over-rides of any other slicer setting, making it very easy to create a solid printer profile, then just modify those parameters for each specific filament (e.g. temps, speeds).

We did some of it with the filament retract overrides. We know a full "last word" of the filament profile over other profiles would be nice, though we have to prioritize.

Yes! I was very pleased to see that feature and I'm making extensive use of it. Your separation of profiles into Print, Filament and Printer is still the best going. (Separate Nozzle/extruder from Printer and you've made me very happy!)

Go bug your Mac user and see if he's got Affinity Designer, the Photoshop alternative. If not, spend some time on their documentation. One amazing feature is that any settings can refer to any other setting. It's almost an Excel macro language. ideaMaker is great in how filament profiles can override other settings, but it would be nice to have it even less bound to the type of profile. Let my filament settings reference the nozzle size and so on. Definitely a wish list item, but one I'd like to see. My goal is to reduce the number of individual profiles I maintain when running different nozzle sizes.

> Every setting is exposed as a variable. PrusaSlicer already does this under the hood, and we can create configs and gcode using placeholders like [nozzle_diameter]. They take it a step further and allow any settings that takes a value to accept either an integer or float, but also formulas. For example, I'd like my layer height to be set as [nozzle_diameter]*0.8. This would cut down on the number of profiles I have to maintain.

That is somehow manageable if these formulas are written just inside the config files. It is much more involved to implement it into the UI. My feeling is the benefits are not worth the effort at least for now compared to the benefits of other requests being implemented.

Fair enough. It's a stretch wish! But give it some thought. If you can allow the interface to freely reference the config variables, it's very powerful. Again, Affinity Designer is very good at this.

Now back to the claim that Cura prints miniatures better than PrusaSlicer. My general stance towards these claims is the following: Please provide me possibly with two project files. One for PrusaSlicer and one for the alternate slicer which you claim does the particular job better. Then I can run the prints and compare the results myself. We really need the Cura profiles and Cura projects to be able to reproduce your claims and see the results with our own eyes. If these claims are provable, then we will likely be more motivated to improve in that particular area.

In reality, I think you can do just about anything in one as the other. The 2 Heroforge models are good examples to work with. Most people are struggling understanding the settings more than anything else. Good use of variable layer heights would help a lot of users. Now that you've added automatic variable layer heights, a major feature gap has closed. If you ask about in the 3D printing groups -- perhaps the Reddit 3dprintedtabletop group -- you might get specific examples from the hardcore miniatures group.

But the one feature I'd really like now is the ability to assign cooling to specific features. The ability to turn on cooling only for external features would be a big help in printing dozens of the COVID frames I'm working on right now!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PrusaSlicer vs Cura

I printed the following using the Cura tree supports and I was positively surprised how well the supports went off. The undersides are not quite convincing though and the supports are fused to the pedestal. I am not sure whether I can do better with some parameter modifications.

https://www.prusaprinters.org/prints/25219-chernovog

I am now printing the model with PrusaSlicer using support enforcers, see the attached images.

> Look at KISSlicer and particularly the pathing used. There are some interesting "tucking" patterns that are worth being aware of.

I did not understand what you mean.

> I like your mention of "painting". The little bricks aren't ideal, but creating modifiers is a bit ... weird. Especially the resizing (e.g. when I want to reduce the height of a modifier slab and it moves both top and bottom to the center). It would be nice to rotate the model on screen and indicate "support here" right on the model instead of trying to interpret from the base.

Placing modifiers by clicking on the mesh would help, though I personally find the UI for the modifiers quite usable. You can also drag a side of a modifier while holding Control key and only that wall will be moved. It works on spheres and cylinders as well.

> In reality, I think you can do just about anything in one as the other.

That's the point. That one slicer prints better than the other is often a thing of parameter settings. I would say that the slicing quality of Cura, PrusaSlicer, Kisslicer or IdeaMaker is quite similar and which one the user picks depends today most likely on availability of fine tuned profiles at first, then on the user interface friendliness at second. Therefore if you guys want to help us making PrusaSlicer more widely used, please provide us with your 3rd party printer profiles. We have a sketchy guide which we plan to improve upon.

https://github.com/prusa3d/PrusaSlicer/wiki/Vendor-bundles-and-updating-process

> If you can allow the interface to freely reference the config variables, it's very powerful.

As of now, if you are going to follow the 3rd party profile guide and you provide us with a system bundle for the installation wizard, you can use a quite powerfull profile inheritance. See our system config bundle for example. The profile inheritance allows you to create a tree hierarchy of profiles, where only the leaves of the profiles are presented to the user.

RE: PrusaSlicer vs Cura

You can also drag a side of a modifier while holding Control key and only that wall will be moved. It works on spheres and cylinders as well.

Holy cr@p, why hasn't that little trick been put into any of the release notes ? Or any instruction anywhere (not that I've seen). That makes manipulating modifiers soooo much more easy. I've seen lots of complaints about it sizing both ways.

I think the single biggest problem Prusa Slicer has right now is the lack of documentation. I know its being worked on and I also know its one of the most boring tasks for a software release and harder than most people realise having had to do it in the past but I think half the issues and complaints would go away if people knew how to properly use it.

RE: PrusaSlicer vs Cura

@neophyl

: Holy cr@p, why hasn't that little trick been put into any of the release notes ? Or any instruction anywhere (not that I've seen).

It is in the description of keyboard shortcuts, see the screenshots.

Mikolas is working diligently on PrusaSlicer manual, the situation will improve.

RE: PrusaSlicer vs Cura

If you want the PrusaSlicer manual improved, it is best to comment directly into the manual.

https://help.prusa3d.com/en/article/general-info_1910

RE: PrusaSlicer vs Cura

@bubnikv

Thanks for that link bubnikv, I will endeavour to contribute.

While I followed it directly there from your post, I also went looking for the knowledge base via just browsing to the Prusa site. Would you mind passing on to the relevant person that it is not easy to find, even when looking for it. It takes multiple navigation clicks PrusaPrinters.org to Eshop to support. Normally I wouldn't visit the Eshop unless I was buying something so that wasn't obvious at all.

Could I suggest adding a link for the Knowledge Base at the top along with the Prints, Groups, World etc on the Main prusa site and also maybe at the top of this forum to make it easier to find. I haven't found a Github for website 🙂

RE: PrusaSlicer vs Cura

I read that Cura has tree support that is easier to remove. Does it leave nicer looking surfaces that interface with the top of the support? Is Simplify3D better at this?

RE: PrusaSlicer vs Cura

I read that Cura has tree support that is easier to remove. Does it leave nicer looking surfaces that interface with the top of the support? Is Simplify3D better at this?

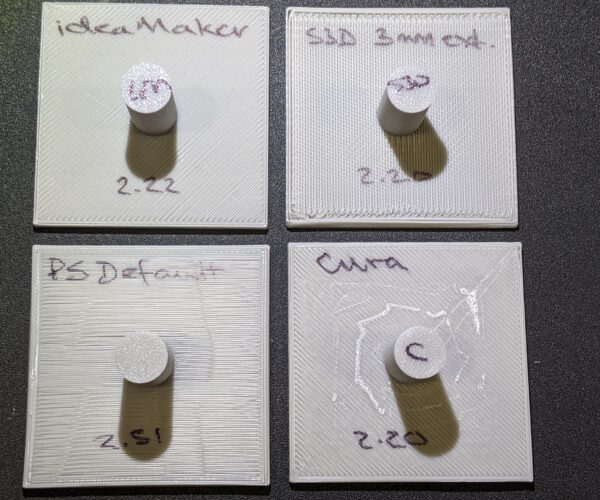

Tree supports are great for irregular shapes like miniatures. If you need to support flat surfaces, other factors come into play. IME, ideaMaker currently has the best removable supports for flat supported surfaces. Here's a comparison using a 50x50mmx2mm flat supported surface printed using (left-to-right, top-to-bottom) ideaMaker, Simplify 3D, PrusaSlicer and Cura (regular, not tree) supports:

PrusaSlicer suffers from the added thickness of the bridge layer beneath the supported surface. This produces a very irregular stringy result and effectively adds an additional layer to the thickness. If you cut back the stringy support PrusaSlicer produces, the layer beneath is very clean.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PrusaSlicer vs Cura

Thanks. My problem with PS is that beneath the supported flat surface, there seems to be an additional layer or two that fused upward sometimes with curled edges. Also that surface is ugly looking.

RE: PrusaSlicer vs Cura

Thanks. My problem with PS is that beneath the supported flat surface, there seems to be an additional layer or two that fused upward sometimes with curled edges. Also that surface is ugly looking.

That is the bridge material I mentioned. I did some research on this topic and found some old posts that indicated there was a reason supports were done this way in the original Slic3r code that made sense at the time. 3D printers and techniques have evolved though, and most of those reasons are no longer valid.

While Team Prusa has made phenomenal improvements to the original Slic3r code, my understanding is that they simply haven't spent much time on this yet. Given the quality of their recent implementation of top surface ironing and monotonic infill, I have high hopes that they'll get around to bottom surface quality eventually. In the meantime, I'm using ideaMaker for those odd situations where bottom quality matters and reorienting the part is insufficient.

There is an ongoing competition between the open-source slicers (Cura & PrusaSlicer) and even the closed-source ideaMaker is stepping up their game. Slicers have improved dramatically in the last 18 months. We're all definitely benefitting!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: PrusaSlicer vs Cura

@bobstro

I installed ideaMaker but could not find the function to import specifications of the i3 MK3S. Did you enter those parameters manually?