Wiard Axis Test fails on Y and sometimes Z axis

New Mini Kit build, completed. Updated Firmware to 4.3.2, it was from factory 4.3.1

In doing the Wizard test X axis test pass, Y axis always fails. Z axis will sometimes pass or fail.

In manual mode of moving axis's X is fine, Y axis moves to front, stops because reaches end of rails, value on screen is 127, move Y to rear, stops at -3 with a physical remaining distance of rail space about 40mm before it would reach the end of the rail. Z axis rotates up to 185 with about 5mm of space left before it would reach the end of the Z axis thread.

I've done factory reset of the machine through the LCD. No change.

All X, Y, Z motor shaft grub screws are securely on the flat side of each shaft. Each motor pully is spaced using the included spanner wrench as outlined in the assembly instructions. All mount screws have been tightened to for motors.

Belts, all belts have been tensioned as described in help documents "sounds like low bass sound".

Electronics board and connections are secured and properly connected as outlined in the online assembly manual.

I've downgraded the firmware from 4.3.2 to 4.3.1, factory reset. Did new wizard calibration test, and the y an z axis failed as before.

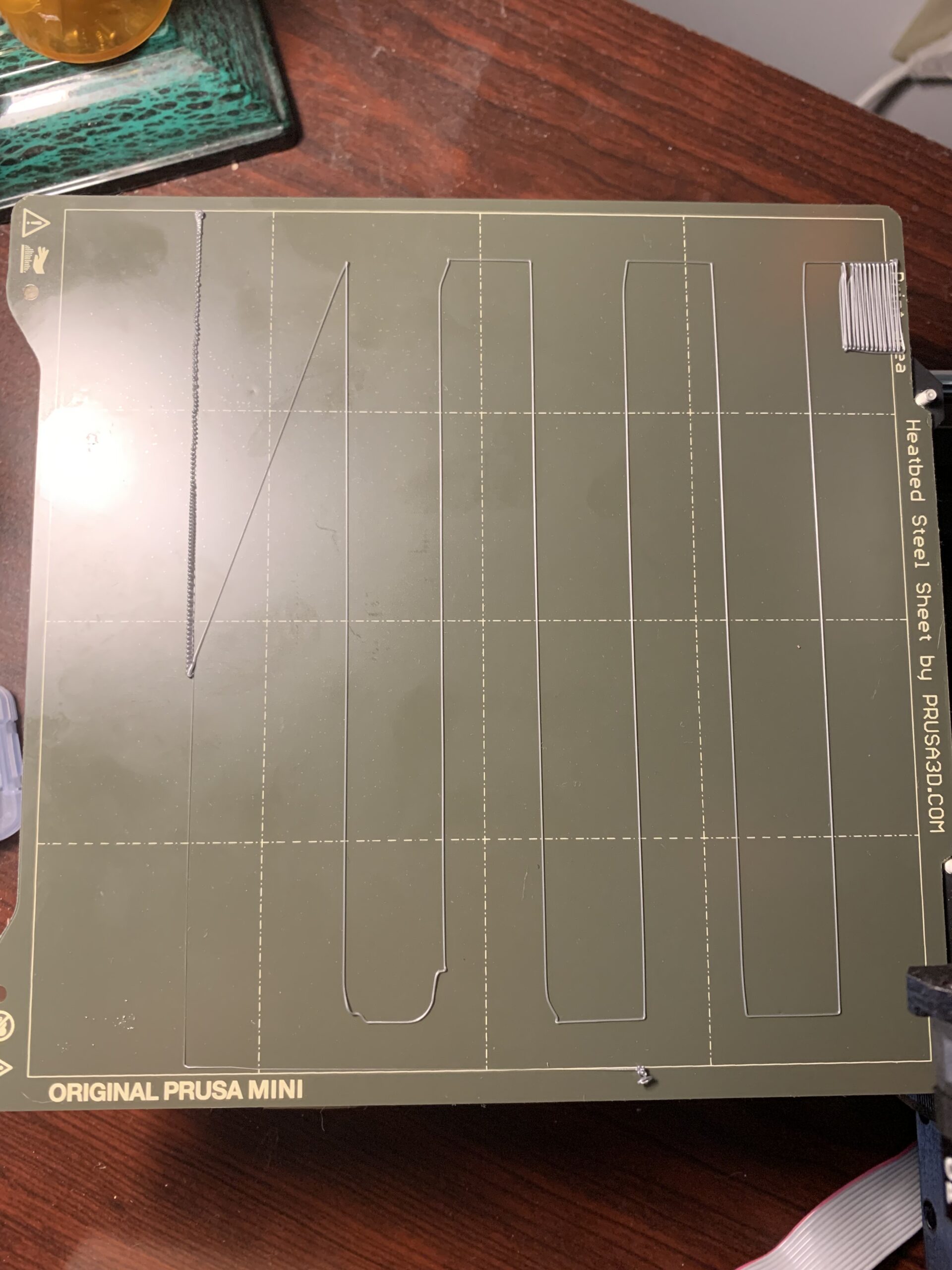

I did a test print and below is the picture showing how far the print bed (y) is off.

Look like there is something wrong with Y axis - it's way off. The calibration layout should be right in the middle not further up.

How is Y-axis belt tension? Is it tension enough? Is belt line up straight? Is motor pinion installed correctly?

I did got Y-axis failure on my first Mini+ and it turned out it was loosen belt. I tensioned it, and it passed.

Not sure why you're getting Z-axis error, but let's do one at a time and focus on Y axis.

RE: Wizard failure Y and Z

The Y axis belt is tight, you can flick it with your finger and get that boing or low bass sound. I have released tension on the Y belt thinking it might be too tight, but same result. I've checked and tightened down all screws on frame rails. When I say tight I don't over tighten. Hand tight with the allen wrench, when I feel that first hint of hard resistance I stop and apply just a half or quarter turn on the bolt.

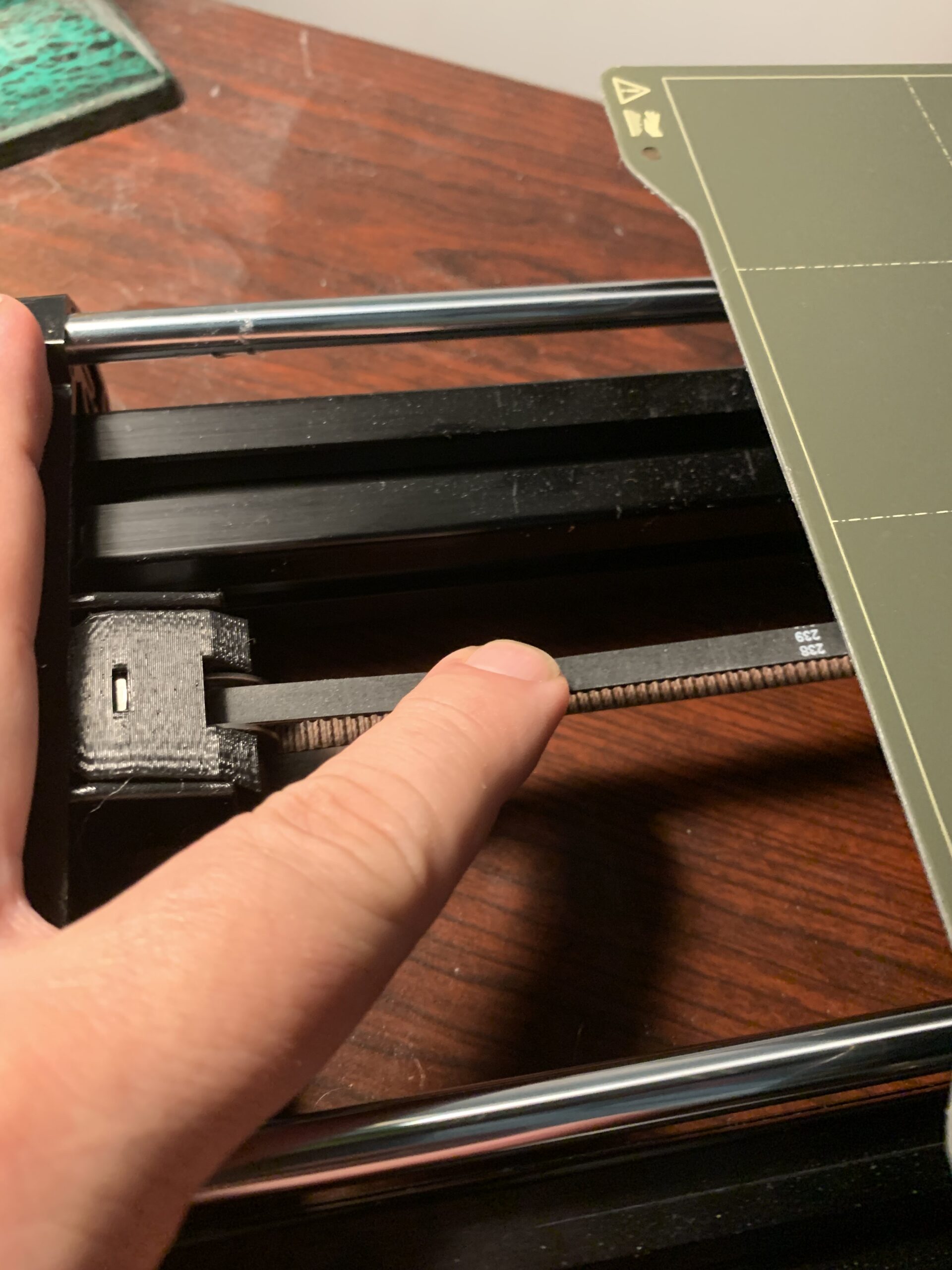

Pictures of the Y belt

Tension on the belt test pushing down

Belt, Motor and Pulley. The grub or stop screw is on the flat spot of the motor shaft. Screws holding the motor in the mount have been checked and tightened also. Spacing of the pulley from the motor is 2mm as the assembly instructions require.

Tension on the roller side or front. I've thought things might be too tight, I've loosened and tested "snug" or loose the same thing happens on the wizard setup.

Seems everything in correct order. Try run selftest again (in Calibration), watch how Y axis behaves. If the bed move up and down quickly without any belt skipping or stuck on both end, then something wrong with it.

I just ran my Mini+ selftest, my bed ran up and down without stopping at ends.

See the video:

If it's all good, then maybe you could contact the customer service - use the live chat in store page (you need to log in). They're very helpful.

Thanks

Thanks for the help and the video. After the bed level test, my Y doesn't move.

Okay. I wonder if the pinion is screwed in... If it is screwed in, check the Y-Axis motor plug if it is fully plugged in. Then that's all I can think to make Y-axis work.

If it still not moving, that means the motor or motor cable or Buddy board issue.

UNLESS anyone can chime in for other possible solution.

RE: Wiard Axis Test fails on Y and sometimes Z axis

Did anyone get the Y axis failure fixed? I have 3 mini's I have not used in a few m0nths. Go to use them and run wizard before I print and all 3 mini's get a Y axis failed - one slide pass to the front and stops (failed "x" on screen). Rebuilt them again, same thing. Funny how all 3 worked great, don't use them for a few months, now all 3 have issues with the Y. Updated the firmware to 4.3.4, same.

RE: Wiard Axis Test fails on Y and sometimes Z axis

My y axis goes to far back and says it's at -3 but its at the end of the rail and that cause the z axis to push down on it and make a creaking noise, I think its because the super PINDA senser had nothing to sense to stop it on the way down to calibrate on the bed.