Two days in - a lot of questions.

I've been working for a couple of days on getting my Mini+ set up correctly. After being convinced that my first layer height was too low, and raising it up, I established that it was too high, and started dropping it - only to end up LOWER than I started out. Learning. I'm fairly certain I have it now, the little square at the end of the test is a solid piece, not strings, and it's only got a slightly discernable texture to it on the top when you touch it.

That said, I'm still having trouble with first layer adhesion. Please bear with me. I was cleaning the spring steel sheet between every print with IPA, assuming that IPA was IPA. I've discovered it was 51% IPA and not 91%. I've JUST cleaned the sheet again with newly acquired 91% - that might solve the problem but it won't answer other questions I have, so.....

Can anyone confirm the sheet that comes with the Mini+ by default is PEI smooth? I'm trying to establish what I can and can't do with this sheet. I paid a visit to a local 3d printing shop to get some filament and advice - and the guy running the place said use hair spray? I don't see that anywhere around here. I'm not trying it until someone says it's safe on the sheet I have.

I'm trying to get PLA stuff to work, and so far the only thing with any height that's finished successfully was the frog sample, which was perfect. I don't know why that finished and then something with a larger surface area did not. I'm sure there will be information people want that I don't know I should provide, but here's what I can think of:

Bed is being cleaned - now using 91% rather than 51% IPA

PLA

215 nozzle temp

60 bed temp

Thanks in advance for help and advice.

A picture of your first layer calibration print on the steel-sheet will help us answer a lot of your questions.

Also a picture of a failed print, top, side and bottom.

We usually suggest cleaning with dishwashing detergent (Dawn/Fairy) and plenty of HOT water.

Cheerio,

RE: Two days in - a lot of questions.

Sheet supplied with Mini is smooth PEI sheet, which is meant for PLA filament. That means, you don't need any sprays (or glues, tapes, etc.) for prints to stick to print sheet! Just make sure print sheet is clean and that you make proper first layer calibration.

If you ever decide to use PETG filament (and you probably will), then you will need textured or satin print sheet for that. In that case, you will need to make additional first layer calibration, because sheet thickness is not the same.

[Mini+] [MK3S+BEAR]

RE: Two days in - a lot of questions.

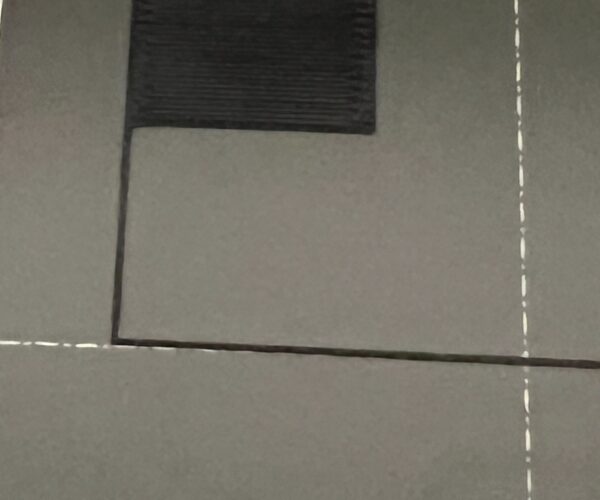

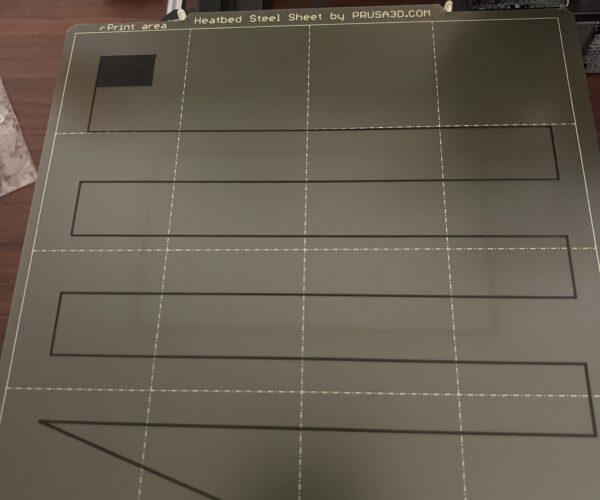

Should have seen that coming - so, this is what the test looks like, lighting is not the best, sorry about that. This setting was arrived at by dropping the nozzle .007 from the last test that didn't result in a solid sheet, and this results in solid sheets consistently.

RE: Two days in - a lot of questions.

Thank you. That is what I thought, but I couldn't find a way to confirm it by a part number or writing on the sheet.

Sheet supplied with Mini is smooth PEI sheet, which is meant for PLA filament. That means, you don't need any sprays (or glues, tapes, etc.) for prints to stick to print sheet! Just make sure print sheet is clean and that you make proper first layer calibration.

If you ever decide to use PETG filament (and you probably will), then you will need textured or satin print sheet for that. In that case, you will need to make additional first layer calibration, because sheet thickness is not the same.

RE: Two days in - a lot of questions.

I have had almost zero issue with PLA adhesion on my Mini. It does come with smooth PEI.

As mentioned, try cleaning with a bit of dish soap and warm/hot water. I've had to do this twice so far and that resolved non-sticking issues both times. I also am only wiping down the bed with 91% IPA every few prints. Really, I print until I see an issue starting, then wipe down and if that doesn't fix it, do the wash.

Mini+ (kit) - Revo Micro | Antler Cooling | WiFi (4.4.0RC1)

RE: Two days in - a lot of questions.

Thanks. I saw that dish soap and hot water was a good refresher for the plate, but it seems to recommend IPA more frequently. After the responses to this post, I did the hot soapy water thing, and a print that had been failing in spite of other prints succeeding finally finished. It seems like I might be getting somewhere.

I have had almost zero issue with PLA adhesion on my Mini. It does come with smooth PEI.

As mentioned, try cleaning with a bit of dish soap and warm/hot water. I've had to do this twice so far and that resolved non-sticking issues both times. I also am only wiping down the bed with 91% IPA every few prints. Really, I print until I see an issue starting, then wipe down and if that doesn't fix it, do the wash.

RE: Two days in - a lot of questions.

IPA after every print or two, dishsoap and hot water after every week or two.

The built-in first layer calibration tool isn't much use for doing anything other than getting in the general ballpark IME. I rarely use it. Much better is something like the 75mm first layer square that you can find in the prints section - using that I can dial my Z height in to something that is close to being perfect. You want it low enough to fully adhere to the bed and "squish" the filament together to produce a nice, smooth surface - but you don't want to be so low that the first layer is too thin, or so the nozzle drags over and disrupts that first layer. I usually point a bright torch at the bed as I'm printing it to get it spot on.

RE: Two days in - a lot of questions.

Good advice on the torch. I've got a big LED torch right on the desk with the printer. I've been using it from the start to see what it's doing, and I've learned what I"m looking for is easier to see with the bright light on it.

IPA after every print or two, dishsoap and hot water after every week or two.

The built-in first layer calibration tool isn't much use for doing anything other than getting in the general ballpark IME. I rarely use it. Much better is something like the 75mm first layer square that you can find in the prints section - using that I can dial my Z height in to something that is close to being perfect. You want it low enough to fully adhere to the bed and "squish" the filament together to produce a nice, smooth surface - but you don't want to be so low that the first layer is too thin, or so the nozzle drags over and disrupts that first layer. I usually point a bright torch at the bed as I'm printing it to get it spot on.

RE: Two days in - a lot of questions.

I play boardgames. Often in dimly-lit pubs. And finding dropped tokens/cubes etc was always a nightmare - until I discovered how useful a tiny torch was. In fact even when looking at relatively well-lit things, a bright torch or inspection lamp can be a huge benefit.

RE: Two days in - a lot of questions.

As you've noted 51% an 91% IPA are two different animals, 91% is best. It could be you're just not getting a good clean. When I clean my bed I pour a small puddle of IPA on the bed, about the size of a silver dollar (38mm) and wipe it around the bed with a micro fiber towel. If there's oil on the bed you want to suspend it in the IPA and soak is up with the towel. I find paper towels don't work as well as micro fiber and can leave contamination on the bed.

Stay away from Hair Spray, it's an old school solution for glass beds, your PEI is superior. A little glue stick may help but only a little, too much glue stick will act like a puddle and make things worse. Angus at Maker's Muse covers how he uses glue stick in this video

I would suggest though only use his glue stick method as a last ditch effort, I usually don't need it.

Prusa I3 Mk2 kit upgraded to Mk2.5s, Ender3 with many mods, Prusa Mini kit with Bondtech heat break, Prusa I3 Mk3s+ kit