RE: Prusa Stringing

Hi All,

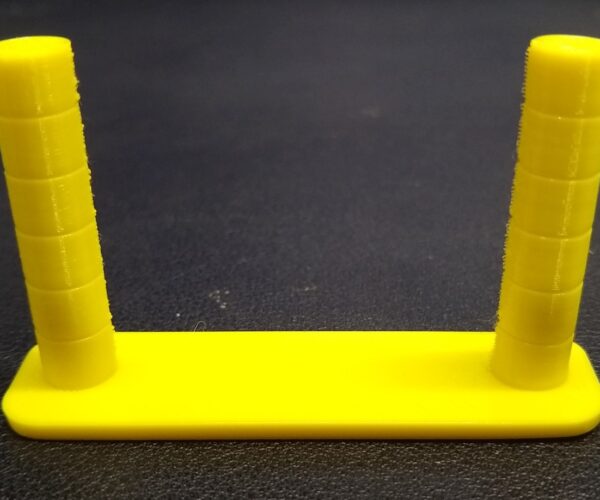

Have tried drying some Amazon Basics PETG Yellow which was super stringy the last time I used it. Dried in a domestic over at 65 Deg C for 4 hours. Seems to perform as well as the PLA. I put retraction settings on the tower of 3.2, 3.3, 3.4, 3.5, 3.6 and 3.7mm. 3.3 seemed to perform the best although there wasn't a lot of difference between them. I'm coming to the conclusion that even brand new filament has moisture in it.

RE: Prusa Stringing

New filament can definitely have moisture issues. The bag seal may have failed, or simply not be thick enough to prevent ingress of moisture. Somebody on these forums did a round of testing and showed that even filament sealed in a freezer bag with desiccant can absorb moisture after a few weeks. I don't recall how well AmazonBasics was sealed, but they're definitely going low cost.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Prusa Stringing

Hello everyone. I'm also having massive stringing issues since day #1.

I tried the provided PLA Prusament samples and my own PLA filament.

To sum things up: I tried many settings (starting with the stock ones and the provided gcode examples) and changes together with the Prusa support.

We realized, that the stringing is almost gone at a whopping 180C... pretty much unusable above 200C (both the sample and my own filament).

So I got a new thermistor and heater... I installed them (the old thermistor was not entirely inside the heatblock and bent from the set screw)... it got significantly worse.

I dried the filaments and got back where I started, lots of thin strings... maybe I little better than before, but still way worse than my 2 year old Ender-2.

I'm still in contact with the support, but since we switched to E-Mail, it's taking some time.

Does anyone have ideas?

RE: Prusa Stringing

[...] Does anyone have ideas?

Have you tried calibrating your extrusion multiplier for each filament? That normally won't account for such extreme issues, but it would be good to at least eliminate it as a problem. The Prusa gcode samples should print much better than what you're getting, obviously.

I've dumped everything I dealt with relating to stringing into my online notes. I'm on a Mk3, so things are a bit different. It sounds like you've tried everything, but it might still be worth a look to see if there's something else. Does disabling Printer Settings->Extruder 1->Retraction->Lift Z (set it to 0) help with parts you slice? Not expecting a big fix with this, but if it changes things, it might give a clue.

Have you done a PID calibration? It should not account for this sort of problem, but it is a good hotend calibration step and you do seem to be having hotend issues of some sort.

Those are all my suggestions. That definitely looks like a retraction-related problem, and the Mini is definitely a different beast owing to the bowden setup. Good luck with it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Prusa Stringing

Hi Finalend4,

You may have tried these things :-

Check the PTFE tube in the hot end, it might be impeding the retraction of your filament. I would be inclined to change it anyway just to eliminate that possible problem. I cut a new one using these tools :-

Extruder tension. Open the door at the top of the extruder to make sure the filament isn't getting stripped. The extruder teeth should be clean.

How long did you dry your filament for? I've now been recommended to dry filament for 12 hours.

I'm now printing at the stock extruder settings in Prus Slicer without issues after drying my filament. If you're changing the slicer settings like retraction etc and it's making now difference then it's probably not your slicer settings.

Good Luck,

Paul C.

RE: Prusa Stringing

Sorry forgot to add link to the PTFE Tube cutter, couldn't seem to edit my previous post

https://www.prusaprinters.org/prints/3644-ptfe-tube-chamfer-and-cut-jig

RE: Prusa Stringing

Thank you @bobstro and @paul-c30 for your advice!

Have you tried calibrating your extrusion multiplier for each filament?

Does disabling Printer Settings->Extruder 1->Retraction->Lift Z (set it to 0) help with parts you slice?

Have you done a PID calibration?

I tried disabling the z hop, it helps a little bit.

I didn't calibrate the extrusion multiplier yet... maybe worth a shot. PID Tuning isn't available yet on the Mini, or is it via gcode?

Check the PTFE tube in the hot end

Extruder tension

How long did you dry your filament for?

I already tried replacing the PTFE tube in the hotend with the spare one that comes with the printer - didn't change anything.

Also played with extruder tension - nothing changed.

I tried the filament @ 50C for 3hrs... I've read 4-6hrs is plenty, depending on the temperature.

On Monday I'll get additional boxes+hygrometers+silicagel-bags for storing my filament after it's dried. Didn't need this for 2 years now with my Ender-2, though my old PLA is really brittle now (not the dried one).

Today also my new hot air gun arrived... just swiping over the print (so like half a second in total) @200C removes all strings at an instant... really nice to watch, not gonna lie.

All in all I'll keep an eye on it - calibrate extrusion and PID + dry the filament for a longer time.

RE: Prusa Stringing

I got really disheartened and upset with my Prusa Mini over the past few weeks so took a step back and left it alone, hence the lack of updates from me on this. It's really taken me down how my Flashforge Finder was producing more reliable prints at better quality than the Mini. It was also easier to use! The snapping point for me was both a literal one and a figurative one, as a print I put on snapped taking it off the print bed. I bought the Mini so I could use PETG which is meant to be a bit stronger and take a bit of flex over PLA, to have something snap so easily off the print bed almost made me bin the printer.

Today I've picked up testing a few things again. Starting with Filament storage. I got some ziplock bags and large silica gel bags and have gone through all my filament reels to store them in airtight bags with silica gel.

Secondly I puchased one of those filament storage units which has the heater element. My oven's temperature STARTS at 75C, so I don't feel comfortable sticking filament in there for any length of time, given that most ovens vary +-10C at the best of times. I put my Prusament in the filament storage thing for 18 hours at it's highest temperature (80C). The thermometer I stuck inside it read 38C air temperature and 10% humidity.

I switched the printer to stock settings and printed a stringing test. Remarkably the print has some stringing but nowhere near as bad as it was. I've got a much better 'starting' point now than I have done before. The print is also stronger and takes some effort to snap.

I'm currently in the process of doing a few more tweaks but with the aim of not lowering the temperature by more than 5c. In short, the filament can get damp quicker than you expect and can effect the print more than you think. Though I'm wondering if it was a combination of the extruder not quite being setup right and filament being damp.

RE: Prusa Stringing

Filament can be wet when opening new spool - aside from sealed bag being somehow not air tight, during filament extrusion it is common to cool down filament in water. While this is short procedure and filament gets dried, therefore chance of it being wet from water itself is small, air around extrusion lines can be humid. They put a bag of dessicant to help with soaking leftover humidity in bag.

I have had PETG out in the air for 3 weeks without signs of being too wet (small stringing but manageable), but it was during winter when air inside tends to be dry. Recently I printed with Prusament Signal White and that thing was a stringing mess after one week on spool holder.