Possible problem with underextrusion

At first, everythings worked smoothly, later i got into issues.

At first i was guessing problem with risft layer. I ddi a lot of testing and ended up with -0.410, distance of the nozzle from plate.

But my problem persists.

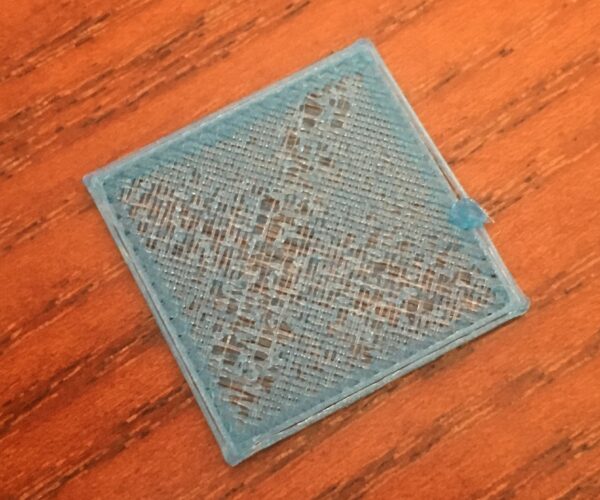

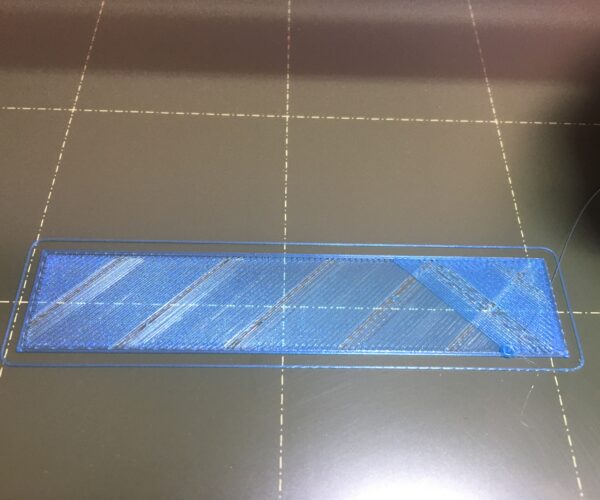

Can some look into attached photos a tell me, what is causing my problem?

First layer test works fine, the problems comes later (second, third layer)

RE: Possible problem with underextrusion

Unfortuantely very common problem with Minis. Look at other forums threads.

Do these steps: https://help.prusa3d.com/en/article/clicking-extruder-under-extrusion-and-clogging-mini_112011/

And be ready to reassamble the hot-end, because it's the most probable issue.

And a little advice: don't try to remove the brass nozzle unless you are ABSOLUTELY sure you know what you're doing and how to do it! Because they like to break and get stuck in the heat block.

RE: Possible problem with underextrusion

@pitel

Thanks for reply. After another cleaning (cold pull, disassembling whole PTFE path, extruder cleaning), it seems to be working.

Test cude came out nicely.

I hope i will not need "heatbeak procedure".

Anyway, thanks again for tip.

RE: Possible problem with underextrusion

Install firmware 4.0.5Rc1

Prusa Mini - FW:4.2.1

RE: Possible problem with underextrusion

I've reduced the infill printing speed to 60% and it's ok. So it looks like lost steps or too small hotend extrusion.

RE: Possible problem with underextrusion

At the end i changed PTFE tube inside hotend and it solved my problem. I used spare one supplied by Prusa. Spare one was tiny bit longer. After recalibration of P.I.N.D.A i works now much better.

thanks to all for answers

RE: Possible problem with underextrusion

Hi Petr,

Have you considered buying more PTFE to have in stock for next time?

I suggest that you get enough to replace the bowden as well, because you will need a new bowden at some time...

Get good quality PTFE because the PTFE restrains your filament during printing, the bigger the internal diameter, the more 'Slop' you will get in the feed path, this will affect retractions and make flexible filament more difficult to print with.

tools to prepare the ends will also be useful to have on hand.

I am not a Mini owner, but I notice that the Mini uses brass couplings with 'Olive's' to restrain the PTFE, I believe Olives work by deforming the edges under compression, to grip the pipe inside the olive. I suspect you may have to replace the olives when you replace the bowden tube.

Good luck. and Happy Printing

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Possible problem with underextrusion

No original Prusa mini PTFE tube for hotend. Only fo bigger brothers of my MINI.

So i have to look around. I found one shop and they ofer 1m long pieces.

About replacing whole PTFE feed path. I hope it will be necessary, because relacing brass parts is not easy withou proper material and tools.

For now, i am OK, everything is working fine and i am down the half of my first filament spool.

Thanks fo hints