Poor print quality on narrow details - ideas

Hi Prusa folk,

New 3d pinter owner here. Overall I've been happy with my new mini - but am having an issue with small details. I'd appreciate pointers for what you'd call this issue and steps I might take to diagnose.

Overall print quality is good, though perhaps with more stringing than I see others getting.

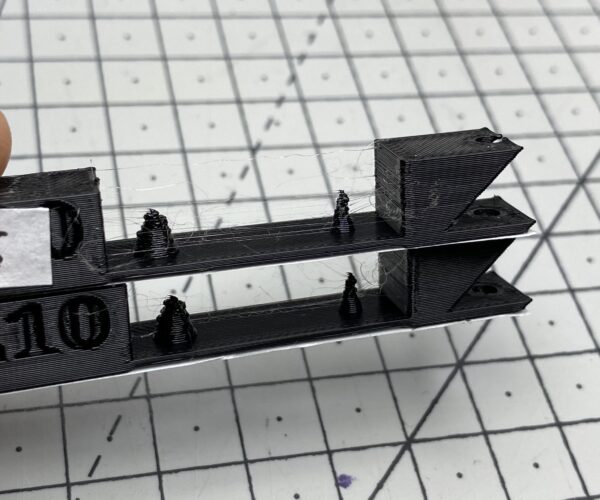

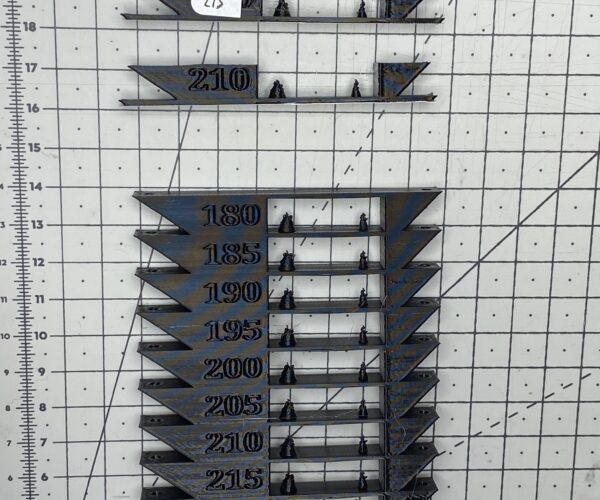

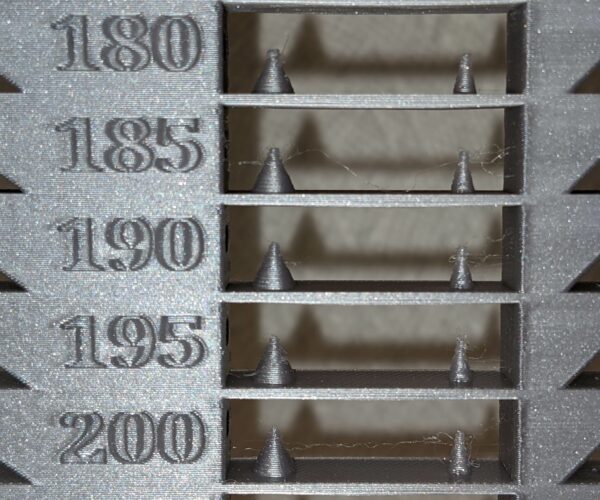

Printing a temperature tower shows particular issue with the small cones - once they get small enough they completely deform at all temperatures. I've seen this also in other small cylinders on parts I've tried to print. On all the other temp tower photos others have shared, I don't see others having this issue.

The full temp tower is below, printed in Prusament PLA with a 0.4mm nozzle. I used the gcode directly from the share - though the settings look similar to stock. There's bits of stringing across but what I'm more concerned with is the poor detail on the cones - where the tops are completely deformed. Watching as it prints - it's not that these subsequently deform - the plastic is laid down poorly with each layer - almost haphazardly.

In case it was an issue with the gcode, I've then sliced a portion of the tower with stock settings at 0.2mm quality profile. The lower slice (210c) is with the generic PLA profile, and the upper one labeled 215 is with the Prusament PLA profile.

I might have guessed the issue is print speed - but as I can't see anyone else printing these towers with this issue - including with Minis.

Many thanks for your help.

Suggestion

I would work with print speed and turn the fan on if it is not. I might be wrong, but it is worth ruling out.

--------------------

Chuck H

3D Printer Review Blog

I wish I had a simple adjustment to offer you, but unfortunately I'm pretty new to this as well, so all I can offer is a comparison and the settings I recall as I noticed that we were testing the same model on the MINI. Learning how to insert custom gcode to manipulate the nozzle temperatures in the right spots along the layer timeline was something I was very interested in, so I never did try the provided gcode. Mine was sliced in PrusaSlicer 2.3.1 and I printed on the smooth PEI sheet from Prusament PLA presets with Prusament PLA Galaxy Silver for .2mm Quality with a .4mm nozzle. I did print with a brim, just out of curiosity, but it was not needed in the slightest.

The Prusament PLA filament presets had me running first, and other layers at 215/60, but our temp tower is supposed to start with 220 and instead of trying to insert custom code in the timeline that far down, I just edited the filament preset for first and other layers to 220 right from the get-go, and let the custom gcode inserts I made along the timeline override where needed. Also on the filament settings tab, I had been running a slightly modified extrusion multiplier ( after critiquing some calibration cubes ran the night before), so I was up 2% from factory presets (1) reading at 1.02

One bit of info that seemed to be missing from a lot of these temp towers and other calibration prints is the infill. After a bit of research, it was suggested to me that when it comes to calibration themed prints, if it's not listed otherwise, assume that it is 100% infill. So that's what I ran with. PrusaSlicer will inform you that to run at 100% fill density that it must switch to a Rectilinear fill pattern, and I clicked OK.

Other than that, everything else was factory defaults. I watched 100% of the first 3 layers and they were the best quality layers I had ever witnessed the machine lay down. I came back to check in periodically to confirm that my custom gcode inserts were being acknowledged on the controller at the start of the appropriate layers and that went flawlessly. As you can see, I didn't have any of the deforming of the cones that you encountered really at any temperature, though the amount of fine string/fluff looks fairly similar.

Prusa MINI+ Kit (fw 4_3_1)

Problem found - diagnosis: I'm an idiot

After much searching, I found the source of the issue - which is entirely my fault. Noting here in case someone else experiences similar.

I diagnosed this after watching the print head closely and being very confident it was not moving smoothly - it was erratic. If I were to personify it, I'd say the print head was drunk. Thinking about why the head might not be moving smoothly gave me the clue...

I've been printing via Octoprint. About 2 weeks ago I installed a plugin 'Arc welder' - which converts short segments in to arcs - in theory to produce smoother curves and fewer points. It seems Ark welder doesn't play nicely with Prusa / the firmware.

Viewing the gcode it produces looks fine - so I suspect the mini firmware has trouble with really small arcs - and converts them to much longer arcs, larger than the diameter they're meant to be drawing. So the mini ends up laying down material outside of where it should. The Arc welder repo notes they have a PR open with Prusa to improve arc support - so perhaps this issue will be fixed at some point.

can confirm this

i also posted this in the german forum, but glad i am not the only one encountering this. Small round features don't come out nicely at all with Arc Welder. Accuracy setting set to 0.025mm and G90/91 box checked as per recommendation. Still, the same prints with and without Arc Welder processing come out totally different. Please use this tool on Prusas with caution.