Overextruding and burning filament with Overture PETG

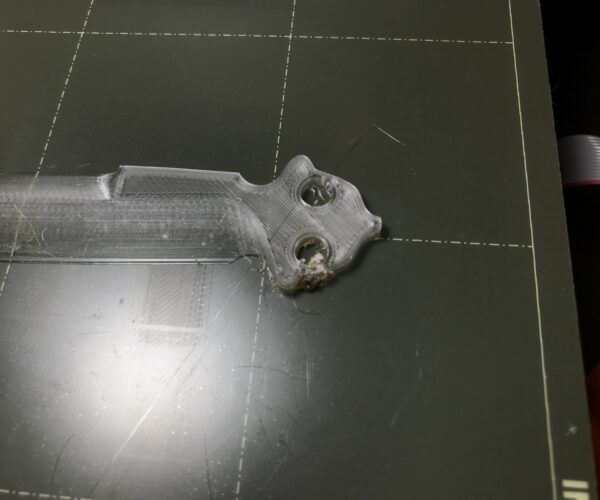

So recently I've gotten my Mini calibrated for this specific roll of Overture Transparent PETG, and as print quality goes it's been going okay. However, I've only been testing on more solid objects, and I'm now trying to make a functional part with tight tolerances. This has become a problem though since I've been running into this problem with the last couple of prints:

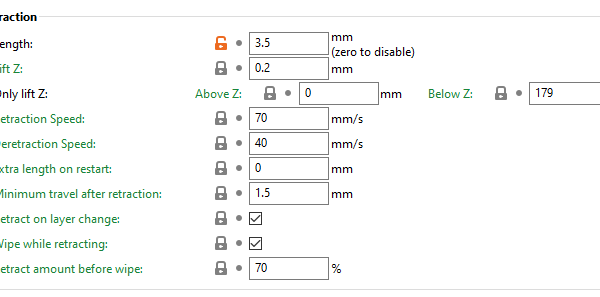

From what I understand, this is a problem with overextrusion; this does track since before and after the prints, I've seen oozing out of the nozzle. What setting could I fiddle with to fix this? I'm really new to PETG printing and although I somewhat understand basic concepts, I've had a lot of trouble with custom settings. My retraction settings are as follows:

I can provide other settings if need be. Apparently, it seems these are using the same retraction settings as PLA as they are bound to printer settings, not filament settings. Either way, any help would be appreciated. Thanks in advance!

oozing

It is either over-extrusion or under-retraction.

--------------------

Chuck H

3D Printer Review Blog

This looks like another damp filament problem, I think you have had them before..?

This time it looks like the first few layers were stringing and blobbing but the later ones were OK. Perhaps the reel was only just beginning to absorb moisture on the outer layer of filament.

Damp will increase dribbling from a hot, idle nozzle, it may look bubbly or curl a little.

You shouldn't need to go over 1mm retraction with dry PETG.

Cheerio,

hm weird

I have had that before, tho I have been trying to regularly heat the filament for like 6 hours within a day of doing the print. This isn't true tho, several layers have had stringing and it's creating these obstacles that make the hole not correctly sized. I'm trying to heat it up while it's printing now, hopefully that'll help. But also for the 1mm retraction thing, wouldn't that change for a Bowden extruder? Default for the Mini is at 3.2 and even then I've found that's too little sometimes.

'Accurate' holes are nearly impossible with 3D printing, the best approximation always involves a certain amount of tolerance. For greater accuracy print undersize and post process with a drill or reamer.

wouldn't that change for a Bowden extruder? Default for the Mini is at 3.2 and even then I've found that's too little sometimes.

It might be, I forget the default; if the filament is expanding due to foaming or steam bubbling the temptation is to ramp it up in compensation but compensating for an unpredictable degree of error is compounding problems.

The object is to cause a moment of negative pressure when required - but if in the process heat is pulled further up from the hot end you risk other thermal problems.

Cheerio,