Now I know why I've had so many problems this evening - x axis out of parallel

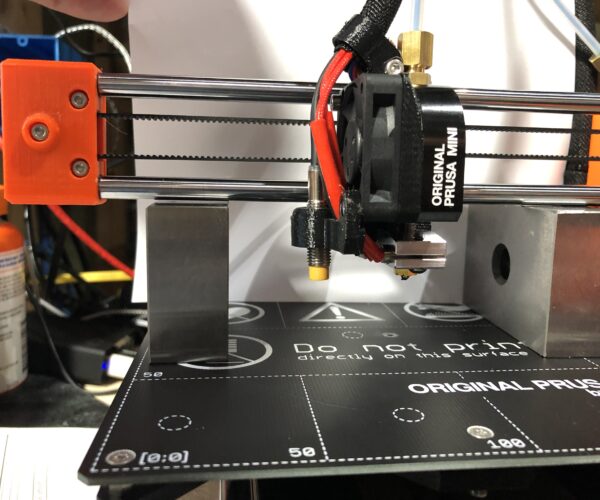

Just got the mini today.

I've been having setup problems all evening. Sometimes setup and calibration would work, sometimes it would say "check your cables" without any actually useful info as to what failed.

Sometimes it would finish bed leveling, sometimes it would just stop.

Sometimes a print would go through the entire leveling procedure and then suddenly go to 100% printed, sometimes it would only make it to the outermost one before going to 100% printed. There hasn't been any useful info.

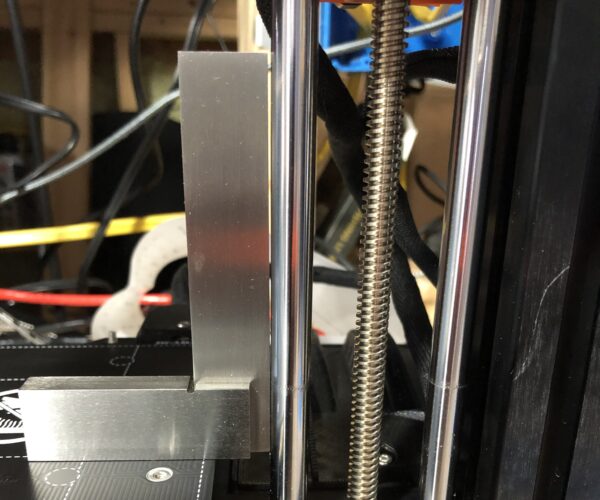

So I checked and my x-axis is not parallel to the build plate. The outside is way up.

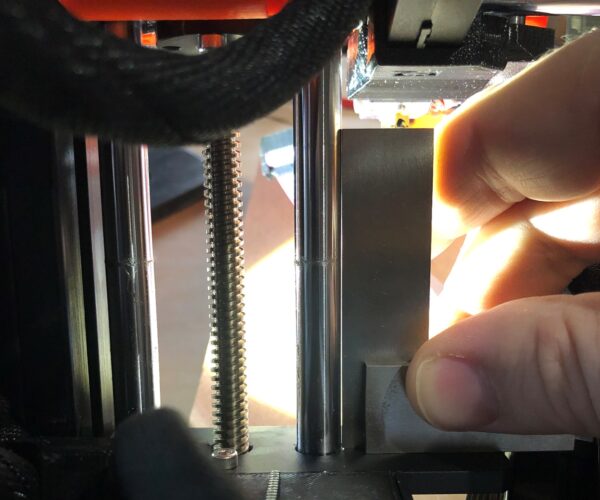

It's unclear where there are any other adjustment points. I loosened the t-nuts the X/Z support and electronics box are bolted to, and pulled the top in as far as it would go. That helped, but didn't quite do it. It's still a credit card thickness on the outside when zero on the inside.

That whole assembly has a ton of flex, and is super sensitive to the flatness of the surface it's on, among other things.

Now that I've taken up the slack elsewhere, I can bend that into position with a little force on the top of the z-axis riser. If I shim the part against the aluminum extrusion, that's not much bearing surface. Of course, with all that flex, I have a hard time seeing how it's going to hold up well enough during a print to actually produce something reasonable. I have seen that others have had success, though, so I'll cross my fingers.

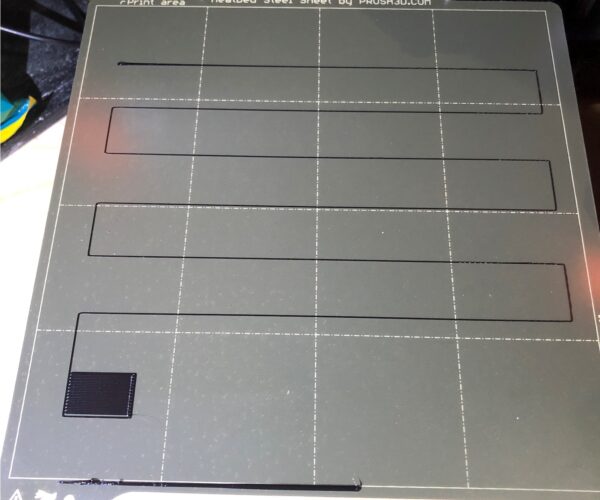

Current status: I've managed to make it past the bed leveling step of a print and am now printing a test piece. In that process, I also noticed that my x-axis is quite skewed compared to the bed (far end is closer to the front than the supported end is). I haven't checked to see if it's skewed compared to Y axis motion (making parallelograms instead of squares), but I will check that next. I assume it is.

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

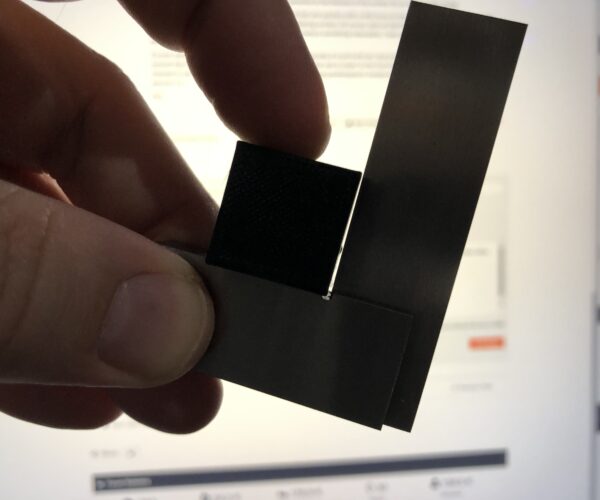

I printed a test cube. Yes, it came out as a parallelogram due to that arm being out of square with the base. Not sure how I can adjust that other than with shims.

No idea why Prusa thought using a 3d printed object as a critical alignment surface was a good idea. Disappointing.

It's hard to see, but it's a parallelogram. (Opposite corner to corner distance is long with one pair, short with the other)

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

BTW, my past experience with Prusa includes the I3 MK3 (pre-built) and the SL1. I've had excellent experience with both. This is the first Prusa I've had to assemble, and it was mostly pre-assembled in the box. In any case, I'm no slouch when it comes to assembling things, I just prefer to use these as tools as opposed to modify them as a hobby.

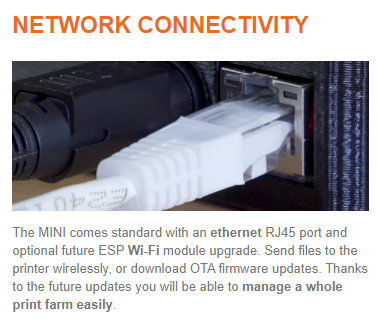

The Mini I received, out of the box, is not that type of experience by any stretch. It was not a Prusa-class experience. I know this was cheap for a Prusa, but, with these fundamental multi-axis alignment issues, the firmware that doesn't give you any info about what has failed when testing/printing, and USB thumb drives as the only way to get a print on the device, I'd say to look elsewhere.

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

@pete-b3

"USB thumb drives as the only way to get a print on the device" Octoprint?

RE: Now I know why I've had so many problems this evening - x axis out of parallel

@pete-b3

"USB thumb drives as the only way to get a print on the device" Octoprint?

Honestly, I'm not really interested in setting up something like that. 3D printing is not my hobby; I 3D print things in support of other hobbies. I like the convenience of how my SL1 does it, and I had assumed, based on the marketing copy on the Mini page, that the Mini would be similar. I do hope that's the case once Ethernet is worked into the firmware.

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

[...] The Mini I received, out of the box, is not that type of experience by any stretch. It was not a Prusa-class experience. I know this was cheap for a Prusa, but, with these fundamental multi-axis alignment issues, the firmware that doesn't give you any info about what has failed when testing/printing, and USB thumb drives as the only way to get a print on the device, I'd say to look elsewhere.

I think part of the problem was Prusa ramping up and (presumably) hiring on new staff to assemble the Minis. Their usual level of QA/QC seems to have slipped a bit. Hopefully they're fixing any problems and there will be fewer out-of-the-box failures.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Now I know why I've had so many problems this evening - x axis out of parallel

@bobstro

Hopefully. But there are some things you really can't get past on the Mini. The 3d-printed alignment surface and Z-axis riser support is a big part of that. There's a metal bit on the top, but when you are tightening things down, the aluminum extrusion and 3d printed electronics box play a big part in how square things are. Plus, there's a lot of flex in the whole assembly. That combination means that shimming is going to take me a solid afternoon, at least, because you have to shim, tighten, and then put it on the same flat surface to ensure the flex doesn't change anything. Doing this in two dimensions at once will be a bit of a chore.

The networking, I hope will come in an update, soon. I'd like to use it like I do my SL1. The copy on the product page has a bit of text at the end which, in hindsight, is a way of them saying the feature is not yet there. But someone looking at it could (and likely would) read it as saying that only the "print farm" functionality (whatever that may be) is coming in the future. Prusa has never seemed like the kind of company that would be deliberately misleading, but I have to squint quite a bit to give the benefit of the doubt on this one.

I think the Mk3 and SL1 set my Prusa expectations a little too high. That said, I've seen reviews saying that "based on my experience with [other Prusa printer], the Mini is a no-brainer", so I'm not the only one.

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

@pete-b3

Giveb how unhappy you are, why not put it on ebay and see if someone bits?

RE: Now I know why I've had so many problems this evening - x axis out of parallel

@towlerg

It's not worth my time to box it back up and deal with ebay. Not for the money it would get for it.

I'm waiting for some decent shim stock to arrive (should be here today) so I can shim this properly. I don't want to use paper, and surprisingly, I have no aluminum cans or other suitable very thin metal kicking around here.

Yes, I'm disappointed because this was not the quality I expected from Prusa given past experience, but if shimming works, and the Ethernet support does actually show up reasonably soon, I'll deal with it. Assuming I don't run into the problems others have with the blocked extruder, that is 🙂

I post, though, because many others have done as I have, and bought it based on Prusa's reputation. This is a budget printer with incomplete firmware. Expectations need to be reset appropriately.

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

[...] Yes, I'm disappointed because this was not the quality I expected from Prusa given past experience, but if shimming works, and the Ethernet support does actually show up reasonably soon, I'll deal with it. Assuming I don't run into the problems others have with the blocked extruder, that is 🙂

Have you been in contact with support? Prusa is usually pretty good about making things right if your product is defective.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Now I know why I've had so many problems this evening - x axis out of parallel

[...] Yes, I'm disappointed because this was not the quality I expected from Prusa given past experience, but if shimming works, and the Ethernet support does actually show up reasonably soon, I'll deal with it. Assuming I don't run into the problems others have with the blocked extruder, that is 🙂

Have you been in contact with support? Prusa is usually pretty good about making things right if your product is defective.

It's a flaw in the design. Others have noticed it and came to the same conclusion. I suspect others have simply not noticed it, but may over time. It's not a support issue.

It's also less annoying for me just to shim it myself rather than explain to someone else on the phone, and then have them walk me through things I've done already.

I never call any support anywhere if I can help it. 🙂

Shim stock just arrived.

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

@pete-b3

Please tell when and how you have done it. Have (more or less same problems and have done nyloc mod to be ok ish to print - but expect better. printing 0.2 ist ok - not good ..)

RE: Now I know why I've had so many problems this evening - x axis out of parallel

You can do nyloc mod on MINI? I am not sure it solves issue with skewed frame and gantry not being parallel though.

RE: Now I know why I've had so many problems this evening - x axis out of parallel

@pete-b3

"I have no aluminum cans or other suitable very thin metal kicking around here." Perfect excuse for a beer run.

You realty should try the ebay route, if it doesn't sell you don'y have to box it if it and it costs nothing to post on ebay. Who knows you might get lucky with some auction fever. Given the waiting list, if a mini was available at reasonable shipping costs, I'd by it at a 10% second hand reduction.

Why struggle with a design that you consider to be so inherently flawed?

RE: Now I know why I've had so many problems this evening - x axis out of parallel

Take a look at my previous post here: https://forum.prusa3d.com/forum/general-discussion-announcements-and-releases/avoiding-early-prusa-mini-issues-common-issues/#post-182742

I have my Mini shimmed.

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Now I know why I've had so many problems this evening - x axis out of parallel

@asdf-tgz

Yep. I saw that after I had posted my info. I'm going a similar route. If I can get it shimmed so both axes are reasonable, then I'll keep it.

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

This evening, I worked on this to get it set up as best as I could. Here are the issues I found:

1. The X and Z axis alignment issues as described earlier

I fixed the alignment issues with metal shims. It took 0.011" of shims on the bottom to adjust out most of the x-axis parallel issue. I also loaded them up a bit more on the far end to help take out as much as possible of the x-axis skew. This took a while because the three screws all affected the axes in different ways. Part of the issue is that the extrusion isn't itself square to the base or print bed. It may be possible to adjust those with the screws on the end, but I didn't want to do that when I knww the shims would address it. The rest is that the 3d printed electronics box is a very compliant surface to use as something to register square. If I were to design this, the Z axis assembly would be metal in more of a T shape, to make sure the registration surface is all metal, and not part aluminum and part 3d printed material. That would certainly add a lot to the cost, though.

Note that I've seen a 3d printed handle for that Z axis extrusion in the mods list (or maybe it was in the model site). Don't do this. You will screw up your alignment if you lift the printer from that axis. Instead, put a piece of flat board underneath, fully supporting all five feet, and always lift it from that.

2. Z axis rails not quite square with their mounting base. (I didn't do anything here, as there's not much reasonable that can be done, and I don't know if the rail is bowed, angled, etc. If it becomes a problem (layers shifted, for example), I'll take another look at it.

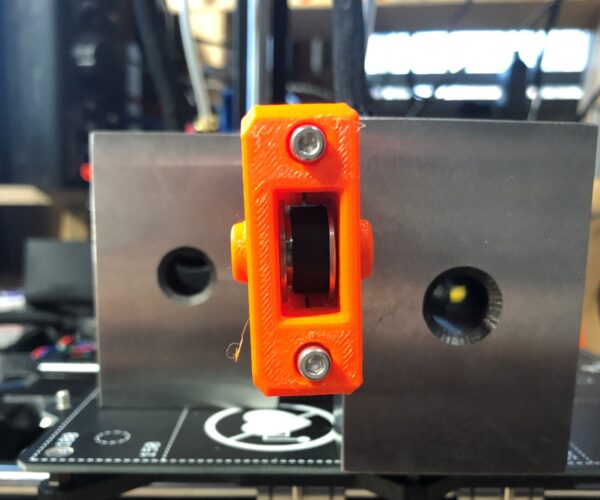

3. A twist in the X axis rails. The two rails were out of plane over the length of the axis. This is easy to have happen because there's really nothing keeping them in plane, other than the end cap, which wasn't screwed in very tightly at all at the factory, in my case. Others may have this and not realize it. It's easy enough to fix with a reliable angle. Note that it wasn't just the cap that was twisted, the rails were out of plane over the length of the axis.

4. Clogged bowden tube. Easy to fix and described elsewhere, so I won't bother covering it. I anticipate this happening quite a bit, but again, easy to fix with this printer by removing the tube between the hot end and the extruder.

5. Access to the USB port (not a problem just something stupid).

I fixed this by ordering a car USB extension. There are lots of clever approaches here, but I went for simple. This is what I bought: https://www.amazon.com/gp/product/B01NAMU8KY/

I used some t-nuts and machine screws to attach it to the side of the extrusion.

After that, the calibration print went a LOT better than before.

This printer is delicate enough that if I were to hit it, or move it, I would go through a fair bit of the above all over again. It's just not a rigid machine. So I recommend mounting it to something that *is* rigid. But any mounting you do should be done before you square up, measure, and calibrate because the mounting itself can pull it out of square.

For now, I have this sitting (not mounted) on a couple 3/4" MDF panels.

I'm printing some test prints. So far, they look cleaner, but I'm sure there will be other adjustments to make after I look more closely.

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

Shims I used:

https://www.amazon.com/gp/product/B00065UX42/

You can also use paper or other things you have handy, but I didn't want anything that would change over time.

RE: Now I know why I've had so many problems this evening - x axis out of parallel

Cube test print turned out reasonably well. It's still not as good as I was getting from my i3, but it will do. 🙂

Pete

RE: Now I know why I've had so many problems this evening - x axis out of parallel

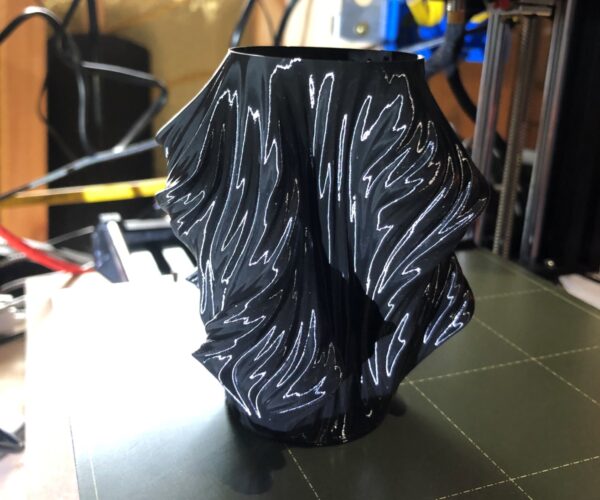

Had to print this on a raft, otherwise the bottom would mess up. But otherwise, in vase mode, this turned out quite nice

Prusament Black PETG.

I also printed the heat bed attachment replacement cover.