Mini + (Brand New) problems with extrusion and filament getting stuck

Hi thanks for any help given in advance (I own a mk3 so not a complete novice)

So I have a new mini+ (as of 31 December and out the box it’s got problems.

It passed its self test

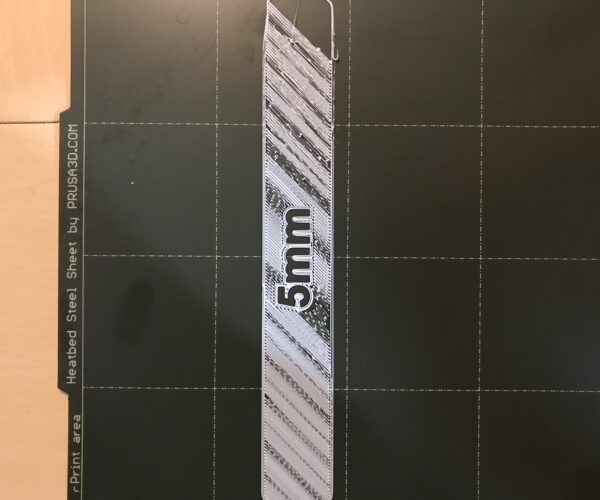

I have loaded filament done a calibration test on the Z successfully when it is extruding OK but this lasts only a very short time till the problems start.

The problem is the printer is constantly under extruding or stops completely and prints in thin air after a very short time printing maybe 2/3 layers, also seems to be occasionally grinding the filament, leading to an occasional clicking noise. When this happens you can’t get the filament out of the machine I have done the steps about heating up hot end etc and pulling and sometimes it works to get it out or I just end up having to do a cold pull (the filament is all crushed for about 15mm from the end and the filament that was near the gears is worn away most times

I was reading another post and watched a video on this forum about pushing the hot end up and the Pinda probe but that does not fix my problem.

I got 2 new reels of filament and tried both of them but have the same problems on both.

I checked I was using the PLA settings

With my limited knowledge my guess is a hot end problem but it seems to stay hot and the printer does not report any problems

Any suggestions?

RE: Mini + (Brand New) problems with extrusion and filament getting stuck

I'd suggest following the steps here https://help.prusa3d.com/en/article/clogged-nozzle-hotend-mini_112011

RE: Mini + (Brand New) problems with extrusion and filament getting stuck

Ender up taking the hot end apart and to be honest did not find any problems but after putting it back together again it started to work.

Anyway its been happily printing away since. I was close to sending it back out of frustration but I decided to sleep on it and start again...glad I did.

RE: Mini + (Brand New) problems with extrusion and filament getting stuck

Glad you got it fixed, 3D printers are not as mature a product as, say, inkjet printers, you will have issues occasionally. Fortunately there are enough people here to guide you towards a fix and you also have Prusa Support available to you.

RE: Mini + (Brand New) problems with extrusion and filament getting stuck

I too received my mini+ just after xmas, put it together, did a system test and first layer calibration (I've an Mk3 I've been using for 3 years now fine) .... The mini printed fine .... the first 3 times ... since then nothing but problems.

- Several cold pulls,

- Replaced the nozzle

- Replaced the ptfe tube in the hot end with that supplied.

- Dismantled and rebuilt the hot end numerous times ...

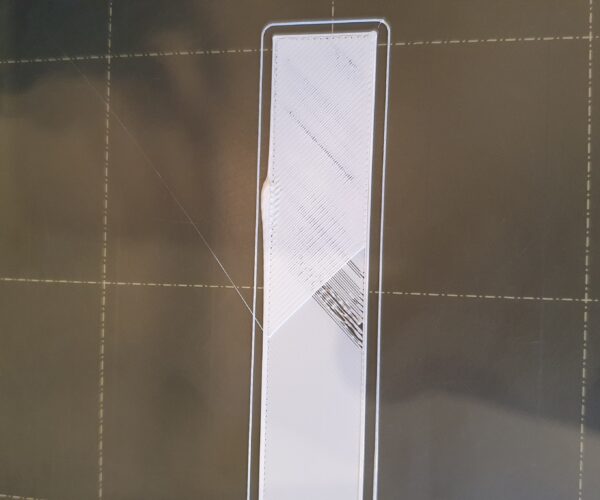

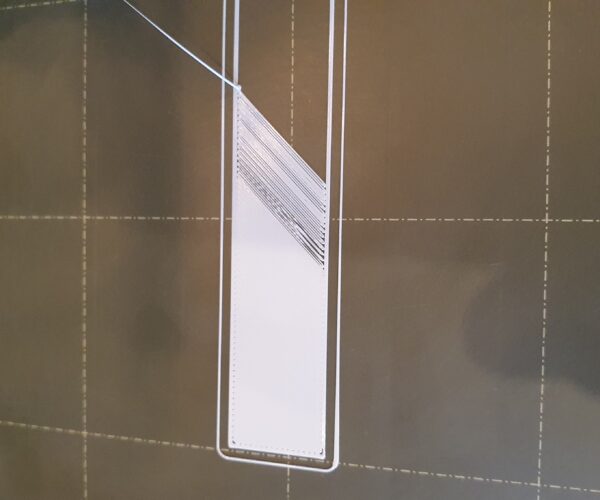

After these attempts I do a first layer calibration and it appears fine ... come to print something on a freshly cleaned print bed ...

Every damn time!

Help!

RE: Mini + (Brand New) problems with extrusion and filament getting stuck

@owt-from-nowt

when i had this the empty slices of your print were also occuring as the extruder slipped (could hear it clicking and chewing the filament in the extruder, pop the little door open and see if your gears are full of filament), up the temps of pla to 225 and in the live tweaking slow the whole print down until you get a stable consistent fill. once you've found that you can change your printer profile to run at a lower speed to avoid needing to tweak all the time.