Live Adjust Z Offset and PrusaSlicer

Hi all,

Apologies if this has been answered before - but I've had some early success and confusion with my new mini and I'm hoping to get some clarity.

For my first print, I used the sample Prusa logo on the USB key after modifying the Live Adjust Z to ~-.800. I then also printed a calibration cube I downloaded from TeachingTech - all good.

Then, I took a PrusaSlicer project I did months ago while waiting for my Mini to arrive and sent it to the printer via Octoprint and noticed that the initial layer was scratching the steel sheet - I panicked and reduced the Live Z to ~.500 and although I'm not sure it actually fixed the inconsistency, the print succeeded.

My question is, is Slicer ignoring my Live Adjust - or is there some setting in my printer/filament/etc that is overriding the calibration I did with the samples? I'm guessing the gcode has something that's altering the starting conditions?

Thanks in advance!

Best Answer by Diem:

Glad to hear it's all working. If you get more first layer problems or adhesion issues then either show us a first layer calibration or the underside of a failed print.

Cheerio,

RE: Live Adjust Z Offset and PrusaSlicer

Slight correction - I used the First Layer Calibration to ~-.800, not the Live Adjust. And I only used the Live adjust when I needed to correct it from PrusaSlicer. Apologies for my confusion.

RE:

Is your "Z-Offset" in PrusaSlicer-->Printer Settings-->General set to zero? Can you paste your startup gcode below?

(FYSA,

RE: Live Adjust Z Offset and PrusaSlicer

Hi David,

Yes, my Printer Settings Z-Offset is 0.

Hopefully this is enough gcode:

; generated by PrusaSlicer 2.3.3+linux-x64-GTK3 on 2021-12-18 at 20:09:46 UTC ; external perimeters extrusion width = 0.45mm ; perimeters extrusion width = 0.45mm ; infill extrusion width = 0.45mm ; solid infill extrusion width = 0.45mm ; top infill extrusion width = 0.40mm ; support material extrusion width = 0.35mm ; first layer extrusion width = 0.42mm M73 P0 R38 M201 X1250 Y1250 Z400 E5000 ; sets maximum accelerations, mm/sec^2 M203 X180 Y180 Z12 E80 ; sets maximum feedrates, mm/sec M204 P1250 R1250 T1250 ; sets acceleration (P, T) and retract acceleration (R), mm/sec^2 M205 X8.00 Y8.00 Z2.00 E10.00 ; sets the jerk limits, mm/sec M205 S0 T0 ; sets the minimum extruding and travel feed rate, mm/sec M107 ;TYPE:Custom G90 ; use absolute coordinates M83 ; extruder relative mode M104 S170 ; set extruder temp for bed leveling M140 S60 ; set bed temp M109 R170 ; wait for bed leveling temp M190 S60 ; wait for bed temp G28 ; home all without mesh bed level G29 ; mesh bed leveling M104 S215 ; set extruder temp G92 E0.0 G1 Y-2.0 X179 F2400 G1 Z3 F720 M109 S215 ; wait for extruder temp ; intro line G1 X170 F1000 G1 Z0.2 F720 G1 X110.0 E8.0 F900 G1 X40.0 E10.0 F700 G92 E0.0 M221 S95 ; set flow G21 ; set units to millimeters G90 ; use absolute coordinates M83 ; use relative distances for extrusion M900 K0.2 ; Filament gcode LA 1.5 ; ; Filament gcode LA 1.0 ;LAYER_CHANGE ;Z:0.2 ;HEIGHT:0.2 ;BEFORE_LAYER_CHANGE G92 E0.0 ;0.2

Please show us a picture of your first layer Z calibration.

Cheerio,

RE: Live Adjust Z Offset and PrusaSlicer

Hi Diem,

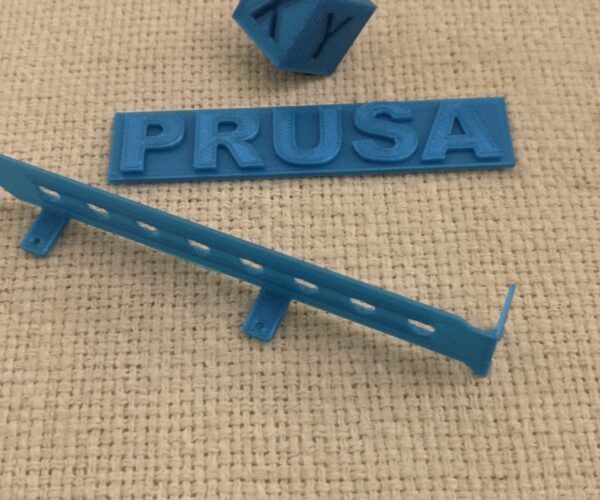

I didn't take a photo of the first layer calibration - but here are photos of the prusa logo, and a calibration cube. The bottom item is the rescued print where I used the live z adjust. I've since reprinted more items from Prusa Slicer and the first layer seems to be starting correctly. Maybe it was a fluke or newbie error.

Glad to hear it's all working. If you get more first layer problems or adhesion issues then either show us a first layer calibration or the underside of a failed print.

Cheerio,

RE: Live Adjust Z Offset and PrusaSlicer

Hi all,

While doing a little nozzle cleaning, I discovered why it made contact with the bed on my first set of prints - my superpinda sensor wasn't secured and could move just by touching it! So I must have moved it without noticing or it could have joggled on its own.

I think the instruction "Tighten the screw on the MINI-minda-holder. Do not use excessive force. Otherwise, you can break the printed part." must have intimidated me - that's my excuse I'm standing by it. 🤣

Thanks for all the input.