Lack of accuracy on mechanical parts

Hello! I am new within 3D printing and I need some advise from you. I recently got a prusa MINI and although those models that comes with it comes out with pretty good results, the issues start when I try to print my own models.

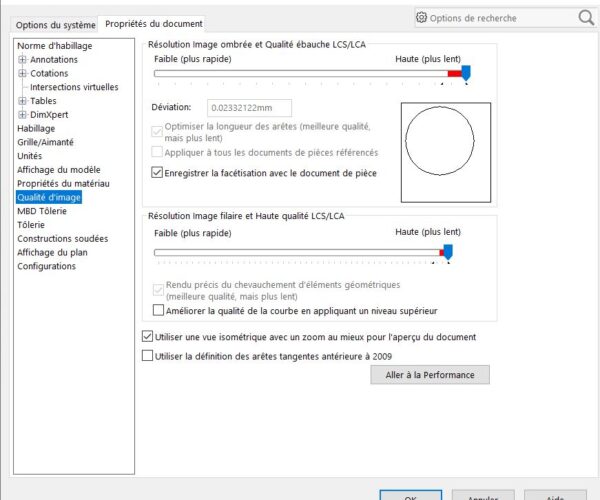

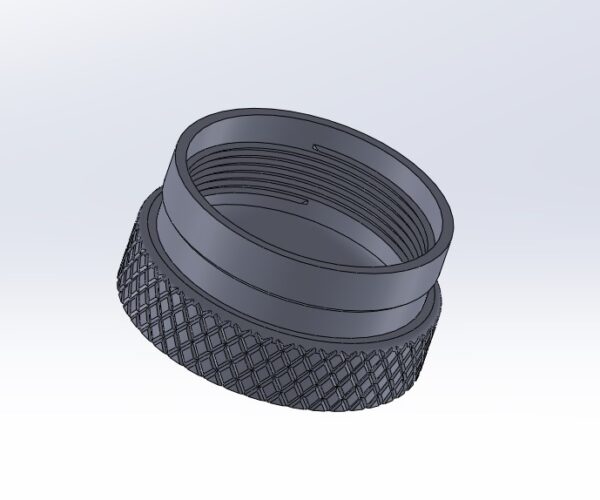

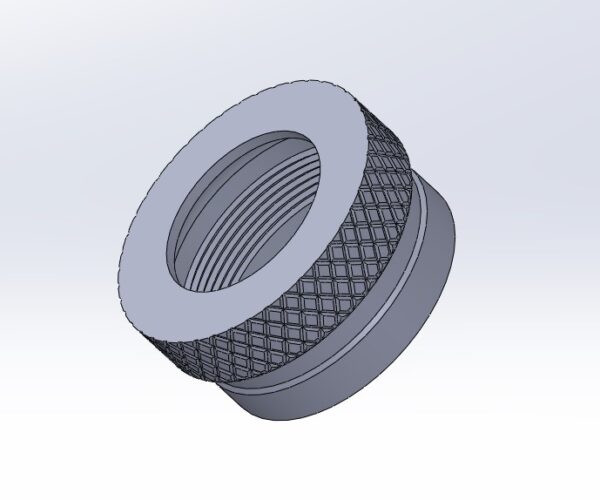

I have started with some basic cilinder shapes which includes some textured details and a thread. ( I have attached images of the original model). However It seems the details does not comes out well defined and the thread seem that suffer from stringing or so.

According to details, along the circle it seems like there is some parts more defined than others and I wonder if it can be caused by a poor axis calibration.

Let me know your thoughts and how you think I would improve my approach. Thanks!!

RE: Lack of accuracy on mechanical parts

I do not have the Mini, but my first impression is that some of your details are small enough to be approaching the line width of the extrusion, thus subduing the details.

Also, threads are tricky to print under the best of circumstances on any FDM printer, particularly without soluble support material. Using a lower layer height can help with things like this, but threads often do not come out as expected.

RE: Lack of accuracy on mechanical parts

Welcome. No harm intended, but it looks like you´re trying to get directly on the motorcyle without steps like learning to walk and learning to ride a bicyle first. It´s cool to be ambitious, but my advice is to learn the basics first about layer heights, fine-tuning the printer settings and limits of the essential parts like different nozzle sizes, clean construction of threads etc. This will help you in the long run to construct and print your detailed, complex parts with an amazing accuracy.

Printing threads will to a big extent be depending on the layer height. If you have a 1mm thread and you print it in .15 layer height, you will get a much worse thread than printing it in .1mm layer height. Small diameter threads may need a finer nozzle (like 2.5mm) to print the details. Finally, make sure to use a good CAD programme such as Fusion 360 - badly designed threads won´t improve when being sliced.

Best

Chris

I try to give answers to the best of my ability, but I am not a 3D printing pro by any means, and anything you do you do at your own risk. BTW: I have no food for…

RE: Lack of accuracy on mechanical parts

Hi 🙂

I also own a Mini + 0.4mm nozzle unmodified, from factory.

Printing my own models 0.1/0.15mm (max) layer height, many with threadings starting from 0.75mm pitch.

Same machine as yours... so you should be able too.

I noticed you said troubles began when printing your own models.

Also on pics you sent outter details don't seem to come out much as well.

Maybe check settings for STL export in the 3D modeling software you're using.

Push details accuracy at max.

For example Catia and Solidworks I'm using those settings are bound to "Options/Document Properties".

Sorry this is in French 😉

This can possibly slow down your computer (if so only turn on details when exporting) and STL files will be heavier...

Though you need max details when printing threadings!

I'm working as 3D Printing Technician and believe me I sometimes have to get back to engineers for better quality exports 😉

Hope this will help! Cheers

That appears to be a very fine thread. If you are designing your own parts you have the option to optomise for 3D printing: Eg, there is no need to adhere to industry standard *metal* thread sizes ... instead of 1mm pitch try 2mm for example. Also try using a more rounded profile than standard, you are building up the thread, not machining it out of a blank...

Cheerio,

RE: Lack of accuracy on mechanical parts

Thank you so much all of you for taking the time to answer! All of you mentioned how fine details requires different technics in orden to make it work so i will try to learn more about that. I highlight some of your advises and notes:

- The importancy of taking into account what are you going to print vs nozzle size and layer height.

-Check settings on my Cad software. I use solidworks as well so i will check that.

- Design parts thinking they are going to be printed Witherspoon some limitations, so change them if needed.

Said that, according to this topics ,would you recommend me some tutorials or useful articles that helps me to learn more about printing mechanical parts?

Thanks so much

RE: Lack of accuracy on mechanical parts

Said that, according to this topics ,would you recommend me some tutorials or useful articles that helps me to learn more about printing mechanical parts?

Plenty of YouTube videos to peruse. Prusa also recently published some online courses. I only looked at their Design Principles for 3D Printed Parts and was quite positively surprised. I think it's a good overview with a few deeper dives into some specifics that could be very useful for someone like you who is kind of new to this topic.

As far as the threads are concerned, I usually don't see many issues if you don't go too small and make sure you have enough clearance built into the design. I usually offset the thread faces by -0.1mm and then fillet the new edge by 0.1mm. Of course, things may depend a bit on thread size.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/