0.6 Nozzle Problems

Setup:

Prusa MINI with 0.6 Nozzle.

Firmware 4.0.5

Bootloader version 1.0.0

Buddy board 1.0.2

Prusa Slicer 2.2.0 (find the gcode attached at the end)

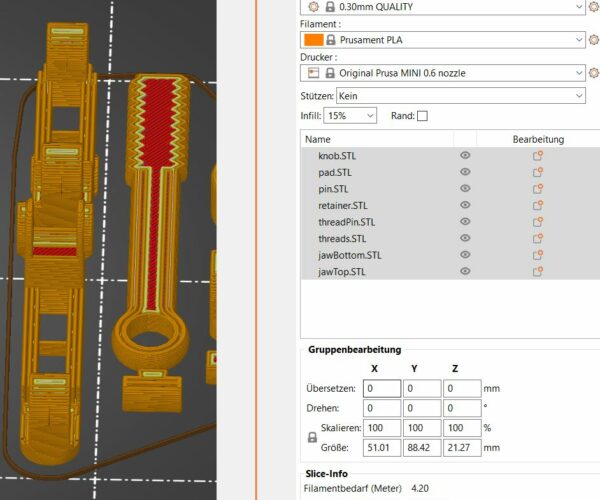

After I switched to the 0.6 Nozzle I have massive problems to get good results, as you can see in the piture below. The two parts in the front starting to have from the height of about 5 mm very bad lines. I realized it 5 mm later and I set manually the temperature from 215 to 220 which seemed to solved the problem a little bit, but still not perfect results.

I removed the 0.6 nozzle again to make sure it was fitted and it was, as you can see in the picture below:

No blue filament on the thread.

RE: 0.6 Nozzle Problems

... adding more information:

Slicer with default setings (including 0.6 nozzle)

Find the gcode here: https://gist.github.com/powtac/5ea2c492e65cbc48a9f6e5c4a7fc6f3e

Using the OctoPrint 1.4.0 on OctoPi 0.17.0 with serial connection.

So what could be the issue here?

RE: 0.6 Nozzle Problems

I did use some noname filament with the 0.6 nozzle first and had bad results as well. The problem mainly was, that the temperature (215 degrees) was too low. So I raised it for the noname filament to 240 degrees which seemed to solve the problem but quality was not perfect, so I switched to the Prusa Polymers filament to make sure the issue is not related to the filament.

RE: 0.6 Nozzle Problems

Prusa MINI with 0.6 Nozzle.

Firmware 4.3.1+2759

Bootloader version 1.0.0

Buddy board 1.0.5

Prusa Slicer 2.3.0

Is there any solution to this? I have the exact same issues. It seems to be a way too high flow rate. So I thought my idler tension was not properly set and tightened the screw. This slightly gave me better results, but I found my idler tension screw is way too tight now.

I used the guide to set the right extrusion width/ extrusion multiplier or flow rate factor. Printed the cube as vase, measured and got perfect width, but when I print an object, my corners are still bumpy (too much extrusion), I see scar marks on the top layers (too much extrusion) and I have gaps between my top layer lines (too low extrusion) which seems to be an issue with the slicer. I also have the bad starting lines which leave a hole in the outer shell. I tried using extra extrsuion after retraction, but no effect on those gaps. I can't find any settings to dial in different flow rates for different types of extrusion (like walls, top or bottom layers) I can only adjust the diameter of those.

For the moment I will switch back to a 0.4mm nozzle as I can't find any solution to this issue and I spent way too much time trying to get it dialed in.

Any help of advice appreciated.