RE: What's the point of an enclosure if the mini can't reach the temperatures for ASA / ABS?

I mainly print ASA DuraPro with the Mini. I don't use an enclosure. Temperatures: nozzle 250 degrees C., bed 100 degrees C. Generally I let the nozzle and bed preheat for about 10 minutes. For larger parts I use a draft shield.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: What's the point of an enclosure if the mini can't reach the temperatures for ASA / ABS?

I have successfully printed ASA with my Mini in a Ikea Lack enclosure. I am using Fillamentum filament and have used most of 3 rolls so far. The Prusa 255/100 temperatures have been fine and the only hint of curling is occasionally the edge of the brim but the actual prints are as reliable as PLA. Reading the causes of warping it can be the design of the model or the G code that can be optimised for success or failure. I don't preheat the enclosure beyond heating the bed whilst I remove the last print and plug the USB key in. My enclosure sits at 35-39 degrees. I was expecting trouble but so far with a clean metal sheet my pain is removing prints rather than them lifting. I do clean with IPA regularly as the removal means I am touching the print surface more than I would like. Being a Mini the bed gets covered from edge to edge frequently. I don't have experience of ABS as ASA is sold as better in every way (except cost?) and I like to keep things simple and not too smelly. The UK winter has meant open windows ventilation and sensible enclosure temperatures would be contradictory. I don't use a skirt.

RE: What's the point of an enclosure if the mini can't reach the temperatures for ASA / ABS?

An enclosure is also great for keeping away

draughtsdrafts which can cause no end of problems!Remember as well not every one lives in the same temperature range. For some an enclosure may be needed to keep ANY warmth!

this 🙂

I set a 6 hour print away on a cold day (printer room was stable at 22c) and running the wood burning stove 3 rooms away it caused a huge amount of curl on the bed over the 6 hours - about 5-6mm at the front edge.

I ran the same print and stove on the 2nd day but put a simple cardboard deflector around the drafty corner and the print was immaculate.

needless to say i'm prioritising building an enclosure now 🙂

RE: What's the point of an enclosure if the mini can't reach the temperatures for ASA / ABS?

I use an enclosure mainly because it looks cleaner and you can reduce the noise significantly.

I printed all the Voron 2.4 parts using eSun ABS on my mini with and without an enclosure not a single problem so far, I reprinted all the parts around the hotend (pinda mount, fan spacer etc) in ABS though.

RE: What's the point of an enclosure if the mini can't reach the temperatures for ASA / ABS?

I print ASA constantly on my mini no enclosure. Last winter it was in the garage and quality only really started to suffer as it dropped below 50F. Nothing I was printing had any real load on it, so layer adhesion was fine. I assume it suffered somewhat vs printing at a proper ambient temperature. I always say, run a print, if you have problems, worry about it then.

RE: What's the point of an enclosure if the mini can't reach the temperatures for ASA / ABS?

As has been mentioned before, I also use my enclosure for draft protection. The room my printer is in is very near my home's front door and my dog isn't always thrilled about going outside when it is raining. My enclosure prevents temperature deviations quite well. Instead of a fully sealed enclosure, mine is somewhat vented at the front and rear.

RE: What's the point of an enclosure if the mini can't reach the temperatures for ASA / ABS?

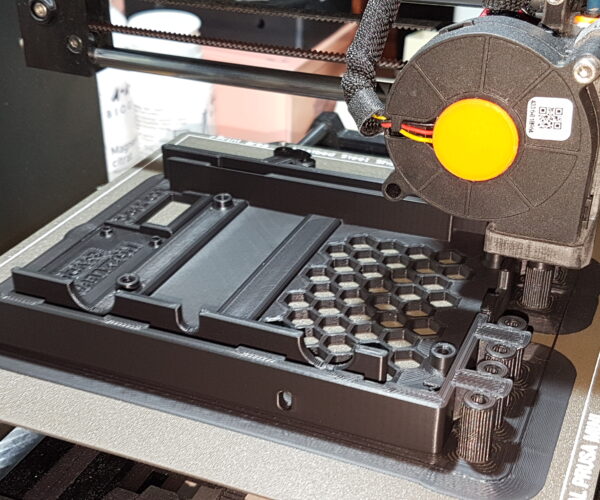

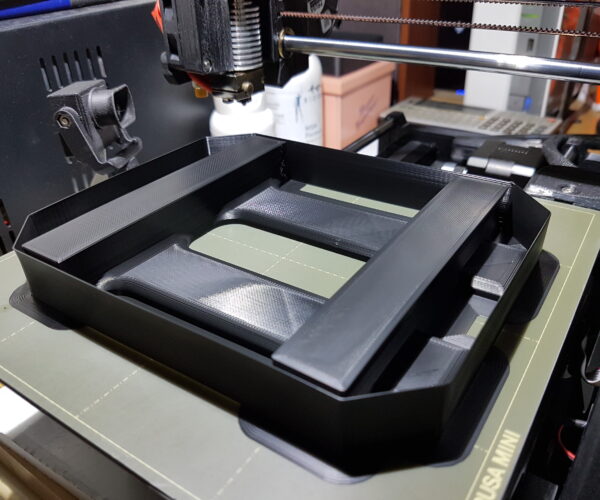

MINI can reach temperatures sufficient to print ASA and ABS, well, at least, it printed Switchwire parts successfully and currently prints Trident parts. My MINI maintains around 45 degrees in its natural habitat after a while. I have it in IKEA Platsa with glass door, and padded walls with 2 layers of styrofoam sheets; I added "ceiling" from coroplast at the height of Z motor, as those parts don't go any higher. I stuck window sealing strip around door as well.

Also, get good surface, maintain it crispy clean and get bottom layer on point. I don't use brim anymore, only on some prints with small surface contact area. I use either smooth sheet, or currently trying Oseq Safesheet. Excellent sheet BTW, highly recommend.

RE: What's the point of an enclosure if the mini can't reach the temperatures for ASA / ABS?

I use my Mini only occasionally. It sits on my desk - without an enclosure. The small Prusa produces quite usable results. But in the future I will place him in an airtight "cage", since ASA and ABS create a somewhat unpleasant oily atmosphere.

happy printing!

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.