RE: V6 on Mini: Heat Creep?

@karl-herbert

Wera is my favorite, along with Knipex.

RE: V6 on Mini: Heat Creep?

@alex-hung

Knipex pliers I also have and in addition some German brands such as Weidmueller, Stubai and also Stahlwille, Gedore, etc..

You pay much more for them, but can use them for a lifetime. Above all, you have joy at work with good tools. Unfortunately, however, many people can not afford expensive tools and for this reason must probably find other solutions.

For this reason, my decision in the price sector "under 1000$) also fell on a Prusa printer 👍

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: V6 on Mini: Heat Creep?

Knipex makes the best split ring pliers around.

--------------------

Chuck H

3D Printer Review Blog

RE: V6 on Mini: Heat Creep?

@cwbullet

What exactly do you use the split ring pliers for? They are often used in the jewelry industry.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: V6 on Mini: Heat Creep?

@karl-herbert

Retaining rings for rocket motors. They hold the nozzles, propellant, and a forward bulk plate in a 29mm, 38mm, 54mm, 76mm, 98mm, or 152mm aluminum tube.

--------------------

Chuck H

3D Printer Review Blog

RE: V6 on Mini: Heat Creep?

@cwbullet

Very interesting, but I can't visualize it now, because I don't know anything about rocket building.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: V6 on Mini: Heat Creep?

@karl-herbert

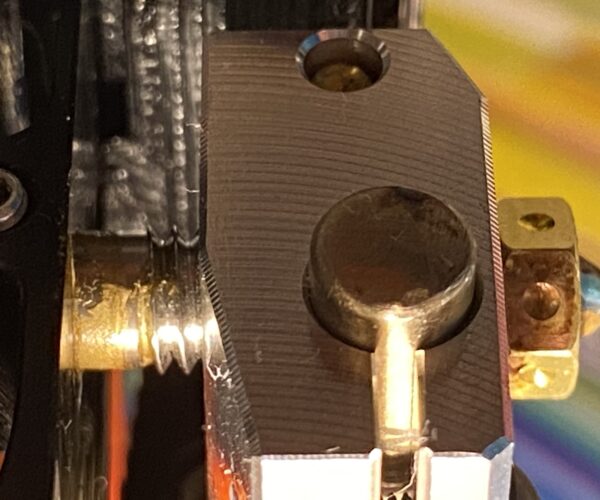

I picked up the Copper Paste you linked me to, and I have placed a new Heat Block and new Heat Break on my MINI, using the Copper Paste

Before I heat it up to 280 and tighten the nozzle a bit, I wanted to check some dimensions with you if I could ...

My gap between the Heat Block and Heat Sink is 5mm, and the distance from the top of the Heat Sink to the top of the Heat Block is 45mm ...Do those dimensions sync with your MINI too ? I still need to clean the paste off the Heat Break in the picture 😀

RE: V6 on Mini: Heat Creep?

@karl-herbert

I will do a thread on a rocket build that includes 3D printed parts

--------------------

Chuck H

3D Printer Review Blog

RE: V6 on Mini: Heat Creep?

@prusatv

Unfortunately, I cannot compare the values because I have installed an E3D V6 hotend. In any case, it is important that the nozzle seals well against the heatbreak and that the hexagonal collar of the nozzle does not touch the heating block.

The gap size between the heating block and the heatsink depends on the length of the PTFE. It is best to read through these Prusa assembly instructions:

https://help.prusa3d.com/en/guide/how-to-replace-a-hotend-ptfe-tube-mini-mini_119449

It is important that the PTFE is well chamfered and seals cleanly at the top (PTFE fitting) and bottom (heatsink) - (STEP 9-11).

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: V6 on Mini: Heat Creep?

@cwbullet

I'm curious about that. I would like to build something in the size of approx. 30 cm with as much detail as possible. It doesn't necessarily have to be able to fly, but it should have a nice place in a 3D print collection.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: V6 on Mini: Heat Creep?

@karl-herbert

I will see hat I can find!

--------------------

Chuck H

3D Printer Review Blog

RE: V6 on Mini: Heat Creep?

@cwbullet

Let me share a part that is a game-changer using the PC4 pneumatic couplings on Bowden tubes. The part that looks like a little C or Pac-Man is what you want to print and slide into the gap of the little locking mechanism and it never slips. I insert the PTFE tube, pull back the lock, and slide this in place.

MonoPrice MP Select Mini Bowden Clip & Extruder Bowden Brace Clamp by A_Makers_Life - Thingiverse

Thanks,

Dave Smith

RE: V6 auf Mini: Heat Creep?

Ok,

I would post pictures but I am at work. I have a V6 installed on one of my Minis. It keeps jamming and when inspected the heatbreak, it was full of melted filament. The PTFE was in the right place. Any ideas what might cause this? I am going to take it apart and reinstall it.

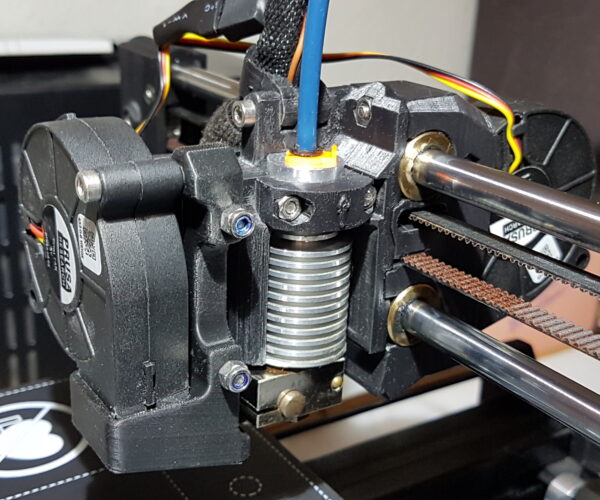

Maybe the E3D V6 hotend works so well on my Mini because I use a nickel-plated copper heating block and a titanium heatbreak with TC nozzle. Same constellation as the MK3.

https://www.prusaprinters.org/prints/42554-original-prusa-mini-e3d-v6-hotend

Das sieht ja interessant aus, gibt es auch STL bzw. .step dazu?

RE: V6 on Mini: Heat Creep?

@daniel-20

Hier: https://www.prusaprinters.org/prints/28046-prusa-mini-v6-conversion-upgrade/related

oder hier: https://www.prusaprinters.org/prints/31006-prusa-mini-v6-hotend-adapter

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: V6 on Mini: Heat Creep?

@daniel-20

Hier: https://www.prusaprinters.org/prints/28046-prusa-mini-v6-conversion-upgrade/related

oder hier: https://www.prusaprinters.org/prints/31006-prusa-mini-v6-hotend-adapter

Das habe ich auch gesehen, aber mit was hast du es Kombiniert, einmal um das Hotend fest zu machen und der Bauteillüfter vorn?

RE: V6 on Mini: Heat Creep?

@daniel-20

This looks a lot like the Trianglelab Prusa Mini.

--------------------

Chuck H

3D Printer Review Blog

RE: V6 on Mini: Heat Creep?

@cwbullet

If you refer to my Mini - it's original from Prusa, only now some things are modified (extruder, hotend, x-end, buddy case, sensors, bearings, firmware, picam, raspi ....) and all parts are reprinted. For testing the firmware a board from Fysetc is mounted.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: V6 on Mini: Heat Creep?

@karl-herbert

I know. I remember. I wonder if Trianglelab used your design.

--------------------

Chuck H

3D Printer Review Blog

RE: V6 on Mini: Heat Creep?

@cwbullet

I had published my designs for a while. Many people copied that. Due to countless requests (and also complaints) I stopped the project development, because I am working full time (community support worker in technical education) and can't spend the time for it anymore.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.