RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

I followed roughly the same procedure that I used when I installed the bontech heatbreak, including the application of thermal paste (I figured it could not hurt). I leave a link below for reference.

0.1 Heat-break Upgrade Kit - Step By Step Guides (bondtech.se)

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@auuru In that document it just shows someone removing it with their fingers. I do not think mine would just come out using just my fingers. :/

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I think I used pliers to remove it, but I don't recall it offering any resistance when I was removing it

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Sadly, I'm going to have to bow out.... The fact that every other filament prints flawlessly and prusament prints fine with one extra turn of tension + slicing with cura is enough for me. I'll still follow this thread, but I've exhausted my current resources (the fact I only have the one roll of Galaxy Black Prusament does not help my testing). Unless I can get more Prusament to continue testing for those who wish to keep the Bondtech heatbreak, this is the only solution I can offer. My final setup is: Bondtech heatbreak, E3D Silicone Sock, and 1 full turn tighter on the extruder tension for Prusament. Standard, flush screw on the tension for everything else. I'm pretty much out of Prusament to continue testing, so in final thoughts... It has to be whatever polymer blend Prusa is using for their PLA that makes it different from every other. Be it, it requires more heat and a little heat creep to print correctly, or it cools too quickly inside the heatblock, I don't know quite yet. If I manage to get more Prusament, I'll revisit and see if I can perfect how it prints while keeping the Bondtech upgrade. Since the PTFE problem is recurring, the Bondtech upgrade is still very viable.

I will still suggest the Bondtech heatbreak upgrade if you print more with other brands of PLA, PETG or other higher temp materials, especially ASA or PC. If you primarily print Prusament PLA, and do not mind checking/changing the PTFE tube occasionally, stick with the stock heatbreak. For those with the Bondtech extruder upgrade, I have no authority to suggest one way or the other, since I do not have that part. I do hope in the near future a real reason/solution can be found, in the meantime, Happy Printing. 🙂

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I've not followed the thread, but there was a comment on one of the Prusa discords (can't remember if it was the official or unofficial one) that bondtech had made changes to the kit and as a result the estep parameter has changed, but they hadn't updated the documentation yet. It maybe worth checking with Bondtech.

Apologies if this isn't relevant, but thought I'd mention it in case it helps!

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I've not followed the thread, but there was a comment on one of the Prusa discords (can't remember if it was the official or unofficial one) that bondtech had made changes to the kit and as a result the estep parameter has changed, but they hadn't updated the documentation yet. It maybe worth checking with Bondtech.

Apologies if this isn't relevant, but thought I'd mention it in case it helps!

@gorden-w do you know when they made changes to the kit? This might be relevant. I don't remember having problems with Prusament before I got the extruder. And I bought mine in November.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@robee-shepherd

I'll try and track down the message I saw on discord, and see if there is more info.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Oh, I think it's worth mentioning. I do not think it has to do with the extruder. I only have the heat break on my Mini, the extruder is stock.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Well, I have the same isssues with prusament - mystic brown PLA, firstly I thought, that filament might be damp (even fresh opened from packaging?), I put it in fruit dehydrator for 45°C for aprox. 12 hours. but it's the same scenario - first cali-cube ok, second - horizontal layers start appearing, and it's getting worse and worse with each cali-cube printed (ended with 4th). Printed with 0,4mm nozzle - sliced in Prusaslicer - PLA Prusament (retractions changed to 2mm, but seems not have an impact on results.)

I have bondtech upgrade heatbreak and extruder installed 5 months ago, and I results was flawless - no more clogging no more clicking of extruder. I have never experienced problems - PLA prusament Galaxy silver 2kg printed without problem, Azure blue 0,5 kg without problem, galaxy purple more than half roll without problem (as the packaging was opened few months ago I have to dry it few hours before print from it last week - but after 10 hours in fruit-dehydrator - print again withou problem.) I have depleted whole spool of Prusament LIME Green and without any problem - all prints ok, even longer of them 6+hours.

For xmas I recieved 6kg of Prusament PLA - opened mystic brown and my problems with horizontal lines and underextrusion started ...

Similar issues I have with PLA Pearl mouse...now it's in dehydrator more than 24 hours of constant drying (but DAMP seems not be the issue)

Now I am printing cali-cubes from that old PLA Galaxy purple to see if there will be same problem as in case of mystic brown / pearl mouse.

So far it seems to me, that some types of Prusament PLA have different ingredients or composition of ingredients has changed over time? Theoretically I can compare old Azure Blue PLA manufactured 1.1.2020 and new one manufactured (1.11.2020) to see what will be result with 4 cali-cubes in row from old and from newer spool.

In tha past I sometimes had problems with underextrusion of Galaxy Black PLA, but I though it's because the spool is old and it might be damp... but seems this will need more investigation ... as PETG is without problem (Prusament) and even cheaper brands of PLA are ok too (Gembird, Sunlu, Nebula, Smartfil, Print-me)

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Few calibration cubes printed.

Bottom line Mystic Brown unpacked few days ago... You can see how it goes from good to worse..

Middle line Galaxy purple opened 8months ago, but recently dryed in fruit dehydrator several hours

TOP line Pearl mouse after more than 24hours sitting in fruit dehydrator..

I will try put Mystic brown to dehydrator for several hours and reprint The 4 cubes to see if it helps..

All printed 0.4mm nozzle, 0.2 layer sliced in Prusaslicer profile prusament Pla

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@pedro_1984

The mystic brown print quite you acquired is disappointing.

--------------------

Chuck H

3D Printer Review Blog

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

so glad I found this thread -

Prusa Mini+ here - got it in December 2020 - was GREAT, then like others, clogged, shrunken PTFE, various other issues (broke a lot of other stuff trying to fix it) - gave up, replaced entire hotend, was perfect again

2 days later, clogged again, PTFE has shrunk - installed the Bondtech heatbreak, but print quality was ... so-so - doesn't matter what gcode settings I do or do not use, its just not quite right. It's not terrible, but definitely not printing like it was new out of box.

Currently debating whether I change thermal-pastes and put paste on everything, or just go back to the Prusa heatbreak and ... I dunno what, replace the PTFE every week? That seems like a terrible solution.

I have some Capricorn XS - would that hold up better in the stock heatbreak?

Like others I've wondered why Prusa sticks with such a flawed heatbreak design, but it seems like the Bondtech version isn't quite right either

Very frustrating how touchy this printer seems to be, but I'm getting VERY good at taking it apart

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

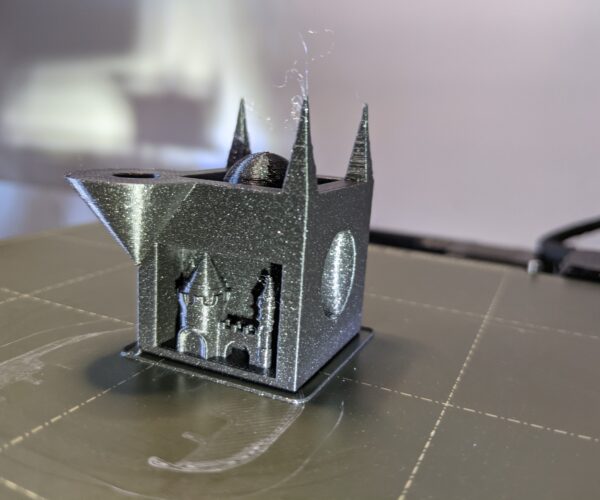

I think I might be onto something, lads. TL;DR info at bottom, since this post sort of got out of hand. Behold, the prettiest calibration cube I've printed with Prusament since installing the heatbreak:

Calibration Cube: Prusament Galaxy Black

I know I got good results with fiddling with Cura and all, but my goal is to try to find out what makes Prusament, print like Prusament, in Prusaslicer. So this was printed with 0.2 Quality, stock, with Prusament PLA profile, in Prusaslicer. This is only a preliminary test, I have a calibration castle printing currently to test more features, finer details, longer print (the castle is at 0.15 and a 2 hour print vs 40 minutes for the cube), etc... Sadly, I only have about 2 full winds left on my Prusament spool, but I couldn't give up trying... So it's all going towards testing and trying to perfect.

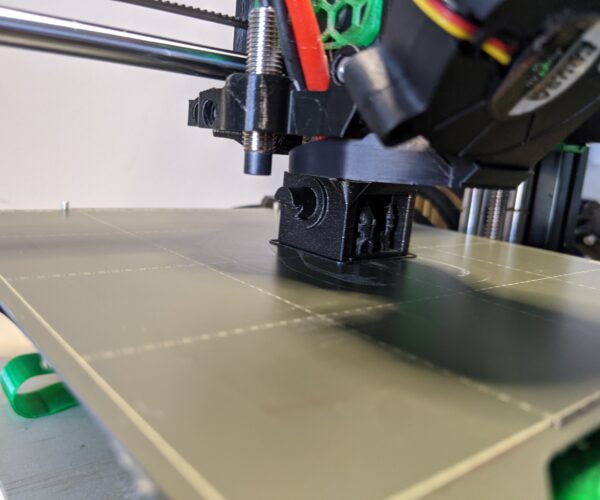

Now onto my testing and setups. First off; The Mini. I only have the Bondtech heatbreak, stock extruder. I took the sock off for now (it's also getting kinda cooked and turning white, so it needs to be changed anyway), but I'm running without it to take out a variable. I AM, however, running a different cooling duct, Found Here. That's the only changes to the printer, I even put the extruder tensioner back to stock flush.

I've been rolling the thought around my head about the effect of heat, how it seems like the mini is designed to REQUIRE a bit of heatcreep as @auruu seems to suggest Here. This would, of course, change the flow properties, nozzle pressure, etc. One would think, simply increasing the temperature would alleviate this, but in my testing... no, it didn't seem to, even printing at 230C. So I've looked at retraction length, speed... Things that would effect how the filament flows and I looked into Linear Advance, something that doesn't come up very often.

https://help.prusa3d.com/en/article/linear-advance_2252

Prusa's article on linear advance does not list the Mini under relevance and the supplied gcode is only for the MK series. So I took it upon myself to use Marlin's linear advance test and modify it for use with the Mini.

https://www.prusaprinters.org/prints/53359-prusa-mini-linear-advance

I had to edit a good bit for the proper accelerations, jerk, limits, leveling, etc. of the Mini. Even by default Marlin put an M501 at the end to "load from eeprom" which apparently the Mini does not store info and zeroed out things like... My Z Live. This naturally had to go and is now completely safe and designed for the Mini. It's designed for Prusament PLA, more relevant info on the test can be found in the print info. Prusa defaults the Mini with a 0.4mm nozzle to an LA 1.5 value of 0.2, after running the test, I had a more consistent extrusion with 0.32, so that's what I went with. Above is the results.

So, an overview and TL;DR if anyone wants to test on their own printer. Try to calibrate the Linear Advance and see if that helps. My premade gcode to test LA can be found above. I sliced this cube with Stock 0.20 Quality, Prusament PLA modifying the custom gcode section to "M900 K0.32 ; Filament gcode LA 1.5", and Bondtech's heatbreak PID in the printer settings' start gcode section. My goal is to try to get good results with Prusament with the Bondtech heatbreak without any real swanky changes, mods, or other hackery. I'll post an image of the calibration castle once it finishes as another data point, either to strengthen what I've found so far, or to say "Welp, that was useless and I'm still at square one!" 🙃 As a reminder, all other filament brands seem to print just fine for me, the issue is solely with Prusament.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@skreelink

That calibration cube is purdy!

--------------------

Chuck H

3D Printer Review Blog

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Always something, bonus points to me for.... forgetting supports. However, the 90 degree overhangs aren't horrible. 🙃 Also correction to my other post, the Calibration Cube was sliced at 0.15mm layer height. I forgot I did that.

Anywho, on to the finished product!

Calibration Cube - Prusament Galaxy Black

It has some strings to be expected on the spires, but... all over it's smooth. The fine details are there and all, but it DOES look like the spires have just a hint of overextrusion. Which is not true! I forgot to turn off the overhead LED ring light I have over my printer (you can see the shadow it casts on the buildplate) and it's reflecting the layer lines, it's actually smooth if you feel it, except the slight bulges where the infill is at. This is most noticeable on the closest fuzzy spire, if it was 100% or 0% infill, that wouldn't be there likely.

Analysis so far: Acceptable prints, especially compared to what it was doing beforehand. I'm going to print a benchy with these settings and see how it goes now, if it passes the Cube, Castle, and Benchy... I might actually have something. I'll need some peer reviews and tests to help confirm if you guys can. 🧐

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

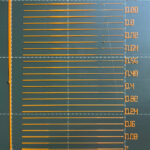

Ran the Linear Advance on my Mini+ with the Bondtech heatbreak and got this - if .2 is 'stock' maaaybe .32 looks the best? It's a slight difference, but my prints are also 'slightly' off - I'll have to run some test cubes later to see

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

There it is, the randomness of the issue. The benchy is looking a little rough. But this gives me more ideas, the LA test I did, definitely helped with larger walls and flat surfaces, as seen on the calibration cube. However, it seems retractions, which have less to do with LA (and since the slicer slows it down for auto cooling as well) seem to suffer. I've included my ASA benchy as a comparison.

3D Benchy - Prusament Galaxy Black; Polymaker Polylite ASA

The bow is standard fair, smooth, a couple lines that are in the light only and can't be felt, but once it begins retractions for the cabin and can't take long sweeps it begins to really artifact. Though, the smokestack is definitely suffering, which leads me to another thought about the heat. It may very well be having the opposite effect than @auruu suggests. auruu mentions they think it's because the filament comes in colder, since the heatbreak is doing it's job correctly, and thus a smaller melt zone, filament is pulling too much heat, thus the printer has to supply MORE heat to catch up, and then it overextrudes... Except... the temperatures are pretty stable, and over large lines would slowly turn into underextrusion, not overextrusion.

My linear advance tests really smoothed out flat surfaces and around corners, as it should. These retraction and slowed down areas, which give the filament more time in the nozzle, seem to still have the issue. Notice in the longer sweeping areas above the doorways of the roof are fine. So my theory is for these areas, since the heatbreak IS doing it's job correctly, it's not pulling heat out of the heat block, specifically the nozzle (since it's directly butted against it). The heat block itself is staying level (according to the thermistor), but since the heatbreak isn't pulling as much heat away, it's allowing more heat to stay within the nozzle and maybe over-melt a little, make the plastic a little thinner, and when detraction happens, it squeezes out easier and thus overextrudes.

I'm doing further tests, currently I sliced the benchy in half to only include the upper 'issue' parts, starting at the port holes and up. I'm going to do the following tests:

1: Lowering the temperature; Maybe the buildup of heat at the nozzle is actually higher than what the thermistor reads, since less is lost through the heatbreak.

2: Try a higher retraction; to pull the warmer filament up further in the heatbreak to warm it up a little more to even it out through the throat and pull any excess back up. This could, however, cause an overextrusion on detraction as it goes faster.

3: Lower retraction + lower speed; Maybe keeping the filament more in the melt zone will help even it out, but also keep the pressures even so it doesn't build up and smoosh on detraction. Similar to reducing blobbing with Flex.

4: Disable Auto Cooling; Since it slows down for smaller layers to help with cooling, the opposite might be happening and letting the filament get too hot and thin, at the same time, it can be laid down faster since it's not as thick.

Mostly I'm trying to think of things that change only with the heatbreak. This can basically only be linked to heat and filament path. The filament path seems to be finely machined, as the results are not consistently bad, if it was catching or dragging, it would be seen no matter what, especially with 'cheaper' filaments that might be BIGGER than the well constrained Prusament. So I'm leaning toward the way the heat moves. We know it works better than stock, the thinner throat prevents more heat from coming up and out of the heater block, so it can keep more heat where it needs to be. This of course changes the flow properties, just gotta figure out exactly how they're changed and redial them in.

I think I know, I don’t think I know. I don’t think I think I know, I don’t think I think.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I'm no engineer, so just tossing out ideas here - it seems like the stock heatbreak lets too much heat pass through, shrinking the PTFE, clogging, etc - the Bondtech doesn't let enough, which causes .. just random weirdness

Has anyone tried the stock heatbreak with a more heat resistant PTFE? (if there is one) - I was going to try Capricorn once I have time to cut a tube and take it all apart again.

I think it was mentioned in a previous post that the Bondtech heatbreak is stainless steel and the Prusa wasn't? What about the Bondtech in a different material? I've seen knock-off version on Amazon made of titanium - although I think Ti is even less heat conductive? May be even worse with those

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Put the stock heatbreak back in - but this time cut & chamfered a proper length piece of capricorn XS PTFE which claims to withstand temps up to 380c - maybe that will shrink less?

Either way, printer is back to printing nearly perfectly 🙄 we'll see how long this lasts

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@prolix21

If only Capricorn sells pre-cut strip of tubing for MINI! I’d buy a batch.