RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I was too quick...

I now printed with white PETG and saw more visible layer lines. I also printed the cube vase and saw more layer lines then i did see before.

Went back to stock and the layer lines are gone.

Will now try with a E3D-V6

RE:

Went back to stock and the layer lines are gone.

Did you change only the hotend ( heatbreak) back to stock or the hotend and the extruder? Are you using 0.4mm or 0.6mm nozzles? (just to have a comparison to my setup)

RE:

Went back to stock and the layer lines are gone.

Did you change only the hotend ( heatbreak) back to stock or the hotend and the extruder? Are you using 0.4mm or 0.6mm nozzles? (just to have a comparison to my setup)

I went back to full stock.

Stock extruder (i don't have another extruder)

Stock heatbreak

Stock hotend.

0.4mm brass nozzle.

I just did a few tests with a E3D-V6, which was better than the Bondtech heatbreak, but not as good as stock.

I now went to all stock again, to do a few more tests i forgot to do and will compare them all

I think i will stay at stock and a capricorn tube inside the heatbreak.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Could you tell me the K-Factor which you got as the result?

M900 K0.34;

I did it only for PLA. PETG runs on stock settings.

To recap every change done to the printer:

Hardware:

BondTech extruder, stock heatbrake, MicroSwiss TwinClad XT coated nozzle .4, silicone sock

Software:

PLA: Under Cooling; Minimal print speed: 20 mm/s and Linear advance - M900 K0.34;

PETG: No changes. I print hotter if I need stronger part

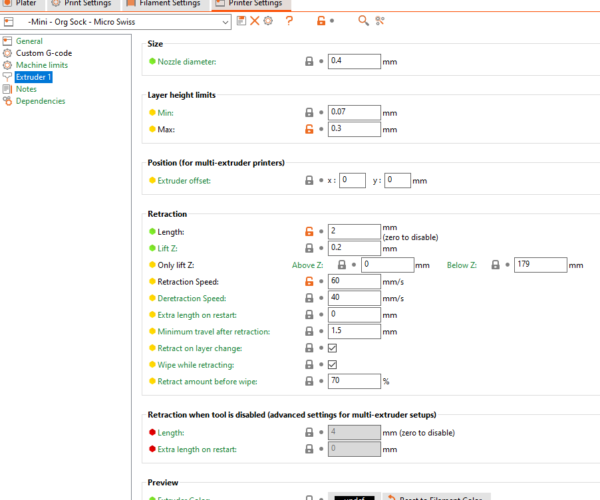

Printer Settings: PID tune (M301 P17.20 I1.57 D47.13 😉 and Extruder 1 - see the image

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

i've been having the same issue with my mini basically since i got it almost a year ago. first i did the bondtech extruder, didn't fix it, just caused more worse clogs. then i got the bondtech heatbreak which fixed the clogging but the inconsistent extrusion was still there. i then did a pid autotune with pronterface and things got a little better. prints aren't bumpy anymore but if you hold them at the right angle the shadows really show how inconsistent it's still extruding. light colors show it the most because the filament will literally be darker where it's overextruding.

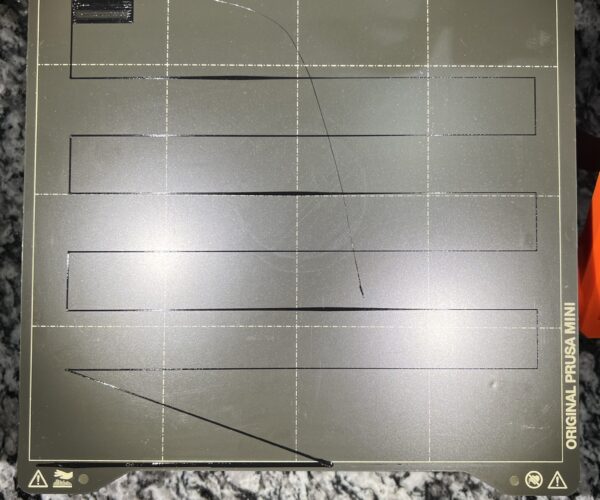

i now have an E3D Revo Micro that i also ran a PID autotune on and it's the best it's been, but still doesn't print as well as an ender 3, which is kind of insane. the prusa mini prints better in terms of details and smooth sides, but the inconsistent extrusion really ruins the look. i print in PETG exclusively because i make car parts and i can't wait to retire the mini because it really sucks. I hope the Prusa XL that i preordered isn't such a turd. attached are some pictures that show how inconsistent the extrusion is. i'm gonna try to put the original Mini extruder back on using the Revo Micro since that's the last option i have.

RE:

Problem solved!

I have a short update: I still have the ComundatMaker3D Dual extruder (<15USD in total with all parts) but replaced the stock hotend (+Bondtech heatbreak) with the dragon hotend from trianglelab. I can now use the stock profiles from prusaslicer and have perfect prints, even now with my 0.6mm nozzle, PetG and PLA. All the problems I had with the bondtech heatbreak are gone. Now it prints how it should have from the beginning…..

I also have no more the strange “cracking” noises. I guess it had to do with the retraction and the heatbreak.

As an input, if anybody looks for a solution. Instead of spending the money on the bondtech extruder, you better spend it on the dragon hotend. And the hint, that there is an opensource alternative for the extruder. I hope this may help you

https://www.printables.com/model/118593-cm3d-extrusor-mini-fs

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Sounds good.

Could you post a link to the Triangelab Dragon you have used?

The links in the mount topic are all too old.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Sounds good.

Could you post a link to the Triangelab Dragon you have used?

The links in the mount topic are all too old.

At the moment the link to the product is this: https://de.aliexpress.com/item/1005002629698126.html?gatewayAdapt=glo2deu&spm=a2g0o.order_list.0.0.21ef5c5fL75RnK

Important: The "normal flow" (not the high flow)

They have no fotos etc. because slice engineering is trying to remove all dragon hotends from the market. If the link is broken (in the future) just write to triangle lab for the link (in the aliexpress app). This is the link to the store https://www.aliexpress.com/store/1654223?spm=a2g0o.order_list.0.0.21ef5c5fL75RnK

The mini dragon hotend mount from Sebastian: https://www.printables.com/model/63259-prusa-mini-mini-dragon-hotend-mount

Wish you good luck. Let me know how it went.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I bought the Paetus dragon.

Used this mount (so far printed in PLA) and with the limited instructions managed to get it up and running.

https://www.printables.com/model/63259-prusa-mini-mini-dragon-hotend-mount/files

with this print cooling fan mount.

https://www.thingiverse.com/thing:4894561

Also reversed the heat sink cooling fan so it sucks through the heat sink.

Can confirm the differernce is night and day. The best i could produce before looks like a piece of garbage compared to standard prusa profiles with the dragon hotend.

Sucks to spend ~80EUR when already spent a bit on the bondtech extruder (Which Im still using)...but totally worth it to not have the hazzle.

10/10 would recomend.

Problem solved!

I have a short update: I still have the ComundatMaker3D Dual extruder (<15USD in total with all parts) but replaced the stock hotend (+Bondtech heatbreak) with the dragon hotend from trianglelab. I can now use the stock profiles from prusaslicer and have perfect prints, even now with my 0.6mm nozzle, PetG and PLA. All the problems I had with the bondtech heatbreak are gone. Now it prints how it should have from the beginning…..

I also have no more the strange “cracking” noises. I guess it had to do with the retraction and the heatbreak.

As an input, if anybody looks for a solution. Instead of spending the money on the bondtech extruder, you better spend it on the dragon hotend. And the hint, that there is an opensource alternative for the extruder. I hope this may help you

https://www.printables.com/model/118593-cm3d-extrusor-mini-fs

RE:

@ Lillalysmasken3

Glad to hear that you solved it 🙂

Yes it's a pity that the mini has this flaws and needs this upgrades to work properly (at least if you are printing on a daily base with it).

For the Triangle Labs dragon hotend I use the stock fan shroud and didn't have any problems. Did you compare the stock to the new fan shroud or did you directly go to the new fan shroud? I'm just curious if you have a comparison 🙂

I bought the Paetus dragon.

Used this mount (so far printed in PLA) and with the limited instructions managed to get it up and running.

https://www.printables.com/model/63259-prusa-mini-mini-dragon-hotend-mount/files

with this print cooling fan mount.

https://www.thingiverse.com/thing:4894561Also reversed the heat sink cooling fan so it sucks through the heat sink.

Can confirm the differernce is night and day. The best i could produce before looks like a piece of garbage compared to standard prusa profiles with the dragon hotend.

Sucks to spend ~80EUR when already spent a bit on the bondtech extruder (Which Im still using)...but totally worth it to not have the hazzle.10/10 would recomend.

RE:

@William

The smart thing to do would obviously be to try one fan shroud then the next.

Another smart thing to do would be to check the heatsink temperature before and after the fan reversal.

I am not smart, therefore I did none of those things...but I now use my mini as the benchmark for print quality. Previously that was my CR10 which prints really beautifully...untill I saw what true beauty was.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

@rinkel

I am curious if you tried it as well and how it went. Did you change hotend?

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Good to hear. I might have to try the parts you used. Those look slick.

@ Lillalysmasken3

Glad to hear that you solved it 🙂

Yes it's a pity that the mini has this flaws and needs this upgrades to work properly (at least if you are printing on a daily base with it).

For the Triangle Labs dragon hotend I use the stock fan shroud and didn't have any problems. Did you compare the stock to the new fan shroud or did you directly go to the new fan shroud? I'm just curious if you have a comparison 🙂

I bought the Paetus dragon.

Used this mount (so far printed in PLA) and with the limited instructions managed to get it up and running.

https://www.printables.com/model/63259-prusa-mini-mini-dragon-hotend-mount/files

with this print cooling fan mount.

https://www.thingiverse.com/thing:4894561Also reversed the heat sink cooling fan so it sucks through the heat sink.

Can confirm the differernce is night and day. The best i could produce before looks like a piece of garbage compared to standard prusa profiles with the dragon hotend.

Sucks to spend ~80EUR when already spent a bit on the bondtech extruder (Which Im still using)...but totally worth it to not have the hazzle.10/10 would recomend.

--------------------

Chuck H

3D Printer Review Blog

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Sounds good.

Could you post a link to the Triangelab Dragon you have used?

The links in the mount topic are all too old.At the moment the link to the product is this: https://de.aliexpress.com/item/1005002629698126.html?gatewayAdapt=glo2deu&spm=a2g0o.order_list.0.0.21ef5c5fL75RnK

Important: The "normal flow" (not the high flow)

They have no fotos etc. because slice engineering is trying to remove all dragon hotends from the market. If the link is broken (in the future) just write to triangle lab for the link (in the aliexpress app). This is the link to the store https://www.aliexpress.com/store/1654223?spm=a2g0o.order_list.0.0.21ef5c5fL75RnK

The mini dragon hotend mount from Sebastian: https://www.printables.com/model/63259-prusa-mini-mini-dragon-hotend-mount

Wish you good luck. Let me know how it went.

@william-2

The Link you posted, leads to a newer version - which will probably not fit the printed parts (because it's not the Dragon Hotend). I am poorly not able to find the correct one, could you give me the correct link? Thank you in advance. Which preferences did you add to the GCode for the new hotend? Just the PID?

RE:

@fly - About the link: I think they changed the product, this is why the link shows something else. I know from the seller that slice engineering is doing everything to get rid of other hotends like the dragon (because they have a patent that makes it impossible for others to use a design like the dragon to split the heatbreak from the mechanical part that holds the heatberblock).

The best would be to use this link to contact the seller and ask for a dragon hotend. If you are unlucky to find one just write me a PM

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Did not try dragon.

Still using a V6, which works fine.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Coming over from this thread (see photos), and I can confirm that the Bondtech heatbreak was causing this issue. Went back to stock and the problem went away.

After combing through this thread I can see you guys already have a large sample size of people who had issues with this heatbreak, I just thought it was weird how the issue showed up for me in a slightly different way.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

I am having the exact same issue after upgrading to the Bondtech extruder and their heat break two weeks ago. Prior to the upgrade, my prints in PLA were absolutely amazing. I upgraded to get better bridging out of PTEG for some functional prints. It's my first 3D printer (and post) so please bear with my noob-i-ness 😀

After my upgrade, I ran a first layer cal and it looked fine. I then tried to print the nut off of the Prusa USB drive and knowing how well the first few prints I did turned out, I just walked away from the printer after starting it. Came back like an hour later and it was a mess. I had commitments during the week, so I couldn't get back to it, but attempted to do a first layer call last night and the photo below is what I got. Now, I also purchased a Mosquito hot end from Slice Engineering and luckily I got the adapters printed in PETG before the upgrade to the Bondtech, so I'm going to attempt to install it and see what happens.

I'm only on page three of this post, and will continue reading tonight when I get home from work, but I'm hoping there's a fix.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Bondtech now delivers some cooling paste with the heatbreak.

This helps a tiny bit, but i gave up on this heatbreak and went to V6.

RE: Strange extrusion problem using Bondtech extruder and heat break on Prusa Mini

Yep, I also ended up getting a v6 lite and printing a mount for it. Haven't had any problems since. Agreed that the stock hotend is killer for first few prints. but then the stock ptfe tube shrinks and melts just enough to create a gap in melt zone which causes clogs. then most people change to the bondtech heat break because its fairly cheap and easy. That works well too, but the break is almost too good, so that will also create clogs on long jobs with lots of retraction.

I'd say the best thing to do is change to a known reliable hotend like v6 or mosquito, or possibly use the stock, but cut a new piece of high temp ptfe like capricorn for the stock break which is less likely to shrink under pressure.

I haven't tried that, but wouldn't be surprised if that helped a lot.