PTFE Upgrade

I've seen where some of you have upgraded your PTFE to Reality Capricorn PTFE with the Quick connect Bowden fittings. Question: Do you end up replacing the original 3 pieces of PTFE (1 inside of extruder exit, 1 between extruder and hotend, 1 inside hotend) with 1 single, continue piece of Capricorn? Is there a good link to performing this mod? Thanks.

RE: PTFE Upgrade

Good question, I literally just did this after my Capricorn XS arrived today. Was wondering the same thing, because I remembered seeing a note that someone had suggested to push the tube all the way through the fitting to the bottom of the heatsink (rather than two independent pieces). I already had PC4/M8 push fits, the Bondtech heat break and extruder and was still getting jams, so I cut a single piece of Capricorn to rule out kinking between tubes (kept the original spool side segment).

Unfortunately, my first print with this configuration still had some under extrusion, but it may have been from a loose thumbscrew on the extruder or a new, heavy spool or using 210 degrees (which is labeled minimum on Form Futura PLA).

I'm hellbent to get a good consistent print, but its hard to say what's goin on. There are some significant curves in the tube ends on the Mini, so I'm thinking that puts a little pressure on the filament as it moves around the plate, so I'm hoping the premium quality PTFE will reduce friction even further. I'm using a reasonable length of tube, and I think its pressed in properly with flat butt ends. It would be interesting to hear what experts say about a single tube rather than two or three piece configuration. I have no expertise myself, since this is my first Bowden experience.

I'm starting to suspect that slicer retraction or PLA temps are the culprit with my under extrusion. I think my z-level is pretty good, I had a couple of short and decent prints before my PTFE upgrade even a -0.020 increase started to jam up the hot end and click the extruder.

Long story short, I dunno. I suspect its better because there's continuity in the pipe, but perhaps independent pieces are better because they don't twist as much? or maybe it's just pretty much the same performance either way?

RE: PTFE Upgrade

I have replaced it with 1 piece. And there is no link just cut and replace

Stock MK4S with FW 6.2.6

RE: PTFE Upgrade

@4m1r

Thanks for the details, I’ll look forward to an update as you experiment more. I find I can rarely get proper extrusion with minimum temps. Was really bad before I replaced hotend thermistor.

RE: PTFE Upgrade

My experiment ended months ago 😊, switched to a one piece boden and it improved my prints a little bit (and maintenance wise) I would not switch back

Stock MK4S with FW 6.2.6

RE: PTFE Upgrade

@oxygen

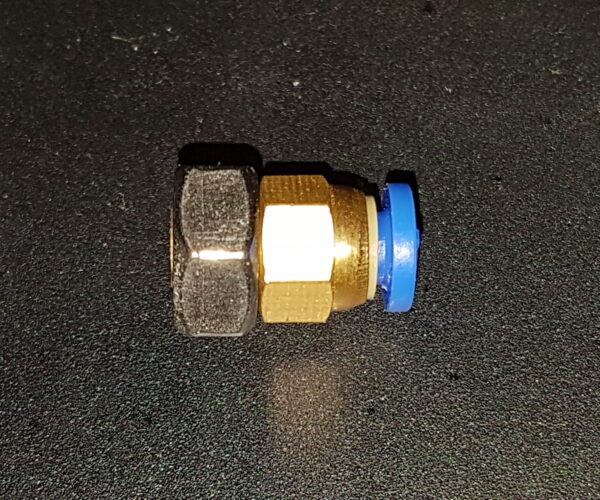

Did you installed the PTFE with the "compresssion nut" on ?

RE: PTFE Upgrade

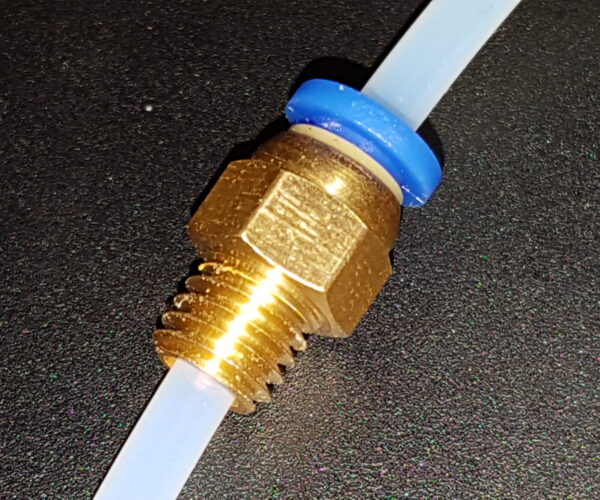

No, first installed the couplers (both ends) compressed the release on the coupler inserted the ptfe tube and switched to the other side (only installed a ring on the hot side)

Stock MK4S with FW 6.2.6

RE: PTFE Upgrade

Update here, been printing a few days with the single piece of tube pushed through to the extruder (about 1cm) and the heat break (about 3cm) using pass through PC4/M8 couplers and so far so good. Not clear if it really makes much of a difference. FWIW, I'm also running the Bondtech heat break and no chamfer on the tube end. More importantly in my case was the PLA temperature. This thread describes my problem / journey so far and is certainly worth a read before you go mucking with the Bowden if you're having jams or under extrusion.

RE: PTFE Upgrade

In my setups don't see any tangible evidence of it making a difference from a printing experience but it is a lot more convenient to take the Bowden tube apart now, without the need to unscrew the brass fittings, which makes it worth it in my eyes.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: PTFE Upgrade

how long should the overall single piece of capricorn be?

RE: PTFE Upgrade

I replaced mine with a single piece. I did not measure the length. I eyeballed it.

--------------------

Chuck H

3D Printer Review Blog

RE: PTFE Upgrade

@toddg

Step 8 and 9 in link below give individual lengths:

adding them up should get you close.

RE: PTFE Upgrade

@cwbullet

I did the same. Mine is probably a bit long because I have to answer no a couple of times when it asks me if the color is correct while loading, but too much work to change it 😇

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: PTFE Upgrade

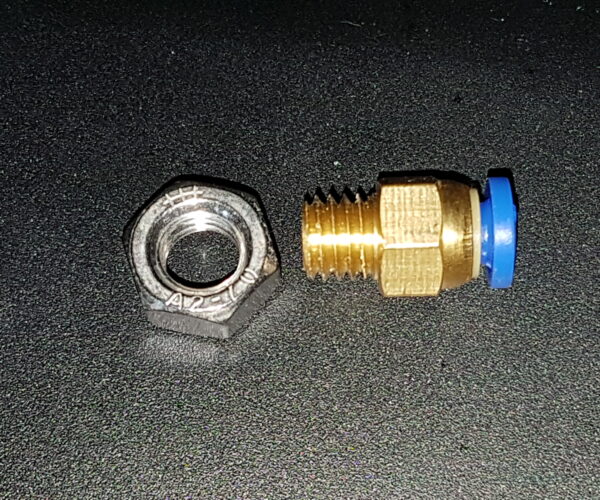

Where did you guys get the couplings?

I ordered some PC4-M8 fittings and they are not a pass through design.

I assume that is what we need for this right?

Any good sources? The aliexpress link in prior posts goes to a seller that explicitly states they are not pass through.

Appreciate the help!

RE: PTFE Upgrade

@toddg

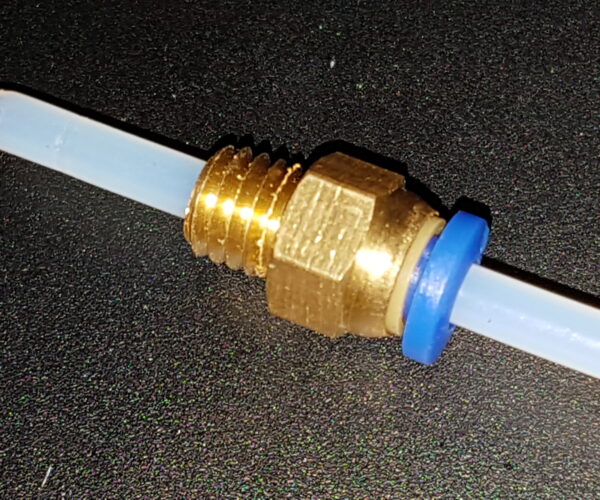

If you mean these, I bought my PC4/M8x1.25 push through fittings here: PC4/M8x1.25

if you need PC4/M8x1.00, you can find them here: PC4/M8x1.00 (however, i don't know if this M8x1.00 is a push through type.)

good luck !

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PTFE Upgrade

@toddg

You're right. My previous link was not pass throughs. I just left the small pieces in the extruder and hot end in. Works fine.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: PTFE Upgrade

@karl-herbert

The ones I got from this link were not pass through.

--------------------

Chuck H

3D Printer Review Blog

RE: PTFE Upgrade

@cwbullet

Then I must have been lucky and they sent me the product I wanted.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: PTFE Upgrade

@karl-herbert

The ones I got from this link were not pass through.

I bought these and also got non-pass-through fittings. I'm going to take a file to one and see if it can be modified enough to allow pass through.