RE:

Is anyone having an issue using Pronterface with the new Mini Alpha update? When I run G29, all I get are probe point values, no complete mesh.

RE: Prusa Mini Silicone Bed Leveling Mod

Is anyone having an issue using Pronterface with the new Mini Alpha update? When I run G29, all I get are probe point values, no complete mesh.

Same

RE: Prusa Mini Silicone Bed Leveling Mod

I have the same problem. Has anyone managed to solve it?

RE: Prusa Mini Silicone Bed Leveling Mod

Yes, "G29 T" works but I get a 6x6 grid instead of 4x4:

Send: G29 T Recv: Recv: Bed Topography Report: Recv: Recv: ( -41,226) (195,226) Recv: 0 1 2 3 4 5 Recv: 5 | -0.009 -0.021 -0.119 +0.005 +0.013 +0.010 Recv: | Recv: 4 | +0.085 +0.030 -0.025 +0.020 +0.023 +0.025 Recv: | Recv: 3 | +0.094 +0.081 +0.069 +0.035 +0.033 +0.030 Recv: | Recv: 2 | -0.051 +0.021 +0.094 +0.045 +0.019 -0.007 Recv: | Recv: 1 | +0.061 [+0.031] +0.001 +0.065 +0.079 +0.093 Recv: | Recv: 0 | -0.031 +0.041 -0.091 +0.085 +0.139 +0.112 Recv: 0 1 2 3 4 5 Recv: ( -41, -48) (195, -48) Recv: Recv: ok

I have the latest Prusa Mini+ 5.1.0 software

RE: Prusa Mini Silicone Bed Leveling Mod

"G29 T1" gives better 6x6 result view for further analysis:

Send: G29 T1 Recv: Recv: Bed Topography Report for CSV: Recv: Recv: -0.257 -0.184 0.007 0.054 -0.058 -0.086 Recv: -0.215 -0.083 0.050 0.077 0.007 -0.063 Recv: -0.055 0.019 0.092 0.101 0.072 0.044 Recv: -0.011 0.050 0.111 0.123 0.085 0.047 Recv: -0.090 -0.059 -0.028 0.039 0.012 -0.014 Recv: -0.229 -0.168 -0.166 -0.045 -0.060 -0.098 Recv: ok

RE: Prusa Mini Silicone Bed Leveling Mod

Can someone please reshare the google doc document because it is not available anymore

RE: Prusa Mini Silicone Bed Leveling Mod

It's been replaced by below. If you read first post it has the link in it.

RE: Prusa Mini Silicone Bed Leveling Mod

has anyone had issues with UBL since upgrading to 5.x? The calculated mesh values for the outer perimeter are off and causing my prints to not stick. I think I’m gonna go back to bilinear meshes

RE: Prusa Mini Silicone Bed Leveling Mod

I‘m having issues with my first layer too. Is it possible to switch back without firmware downgrading?

RE: Prusa Mini Silicone Bed Leveling Mod

Hi all,

@rockytoptim, dindn‘t checked it 100 % but seems to be setup for MK3, is that correct? As the position of sensor is different, it might not work accurately on mini, just guessing. Anyone any experience with this?

It's been replaced by below. If you read first post it has the link in it.

Currently I am downgrading for leveling and upgrading back again. Sound annoying at first but is not that much effort and gives me the best results. I wrote a short guide here: https://forum.prusa3d.com/forum/postid/692974/

Regards

Felix

RE: Prusa Mini Silicone Bed Leveling Mod

Cheap source for tubing - $5 shipped for 1 foot - https://www.ebay.com/sch/i.html?_nkw=silicone+vacuum+hose+3mm+id&_sop=15

MK3s / My IKEA Lack enclosure

RE: Prusa Mini Silicone Bed Leveling Mod

Even cheaper source of tubing. While taking my blood pressure with an arm cuff style BP monitor. I noticed the black tubing between the cuff and monitor was a silicone material. After checking the outside diameter, it matched all requirements needed for this Leveling Mode. After removing a short length for the mod, I found it worked and no harm to the Blood Pressure Monitor.

RE: Prusa Mini Silicone Bed Leveling Mod

Hi all,

I'm trying to do this mod. After few iterations, I wanted to see how stable are results, to see if I'm doing it correctly.

But for some reason, results vary quite a lot (currently, from 0.378mm to 0.546mm). Before continuing, I wanted to check if this is normal during leveling procedure, and it'll stabilize once I get to 0.0xmm difference?

These are screenshoted results of 5 consecutive probes, without doing anything else: https://imgur.com/a/dSezwbH

Thank you for your help.

RE: Prusa Mini Silicone Bed Leveling Mod

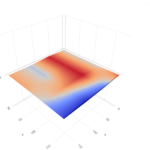

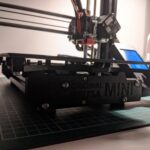

Introducing the world's most level Prusa Mini bed.

(idea from Paul_GD, prusa3d Discord)

(Click to enlarge)

What you need:

- Length of 3mm ID 7-8mm OD high-temperature silicone tubing (can be found in car parts shops)

- 8 M3 low-profile nylon locknuts

- 8 M3x16 flat head countersunk Torx screws (hex will not work)

- 3mm combination wrench

- Computer with Pronterface or OctoPrint

- Micro USB cable

- Torx wrench or driver (recommend key for precision in later steps)

- Tube cutting jig ( https://github.com/PaulGameDev/PrusaMK3_Silicone_Leveling )

- Razorblade or sharp knife

Directions:

- Make sure your X-Z assembly is square with the Y assembly. If you can't get it right, try shimming.

- Power off the printer.

- Cut 8 pieces of silicone tubing using the jig linked above. Or if you have a steady hand, cut 8 x 10mm pieces without the jig.

- Remove printbed

- Remove heatbed (Follow the reverse order as stated here: https://manual.prusa3d.com/Guide/7.+Heatbed++&+PSU+assembly+(textile+sleeve)/589#s9738 )

- Remove the 8 3mm screws and spacers along the outside of the Y carriage (leave the center screw & spacer)

- Replace the heatbed while placing the cut silicone tubing between the carriage and the bed. Place the 8 Torx screws through the heatbed, silicone tube and carriage to hold it all together.

- Carefully apply pressure to a corner Torx screw to compress the silicone tube and loosely attach a low-profile 3mm nut.

- Go to the opposite corner and do the same. Now the other two corners and then the remaining screws. Be very careful here, you can break the heatbed if it bends too much.

- Start tightening the screws back into place until approximately 6mm between the Y carriage and the heatbed. ONE TURN EACH! This takes a while but ensures you get it back on level and without unnecessarily stressing the bed. (Follow the order as stated here: https://manual.prusa3d.com/Guide/7.+Heatbed++&+PSU+assembly+(textile+sleeve)/589#s9738 )

- Now screw in the center screw until tight.

- Power on the printer

- Plug in USB-B from computer to the printer

- Fire up Pronterface or OctoPrint and hit the connect to printer button

- In the bottom right text box, enter the following GCode followed by the enter key. `M104 S170` set extruder temp for bed leveling

M140 S60 ; set bed temp

M109 R170 ; wait for bed leveling temp

M190 S60 ; wait for bed temp- Once the temperature has reached the target, input the following GCode

G28 ; home all without mesh bed level

G29 ; mesh bed leveling- Now, wait for the mesh leveling to complete.

- Copy results and paste them into the spreadsheet (B3:E6) here: https://docs.google.com/spreadsheets/d/1iDbB3aLflnnJze0St2_mDPMZZynlTgUOanb5mXP_Qng/edit?usp=sharing (make a copy first)

You might need to remove any `+` signs- Copy results (A12:H18) and paste them into the website here: https://pcboy.github.io/g81_relative/

- Follow the instructions for which screws to turn and how far

- Repeat steps 18-21 until the numbers from the results section on the website are no more than .02 difference between your biggest and smallest numbers.

- Run Z calibration again resetting the current value. You've just changed the height of your print surface and you don't want to crash the nozzle into it.

- Spend loads of quality time printing the bottom 2mm of Benchy and getting that live-z value perfect.

Notes:

- Why not the Nylock Mod? It's not that simple on the Mini. The Silicone Mod is superior in my opinion anyway.

- Why Torx screws? Because the Mini's heatbed screw holes are not as deep as the Mk3's. Hex screws will sit proud of the bed.

- Why low-profile locknuts? Actually the only area the low-profile locknut is required on is the top center mount point. This allows clearing the Y-axis motor mount.

- If you cannot find low-profile locknuts, you can use regular ones, but you will need 18mm 3m Torx screws. However, the top center point REQUIRES a 16mm Torx screw and low-profile locknut. If you cannot find a single low-profile locknut, you can sand one down to at least 3mm height.

I take no responsibility or liability, for any damages including, but not limited to indirect or consequential and/or loss of life.

More pictures coming soon.

Today i do the Silicone Mod and at the first try i got this result:

RE: Prusa Mini Silicone Bed Leveling Mod

Hello, I am going to make a mod, but it seems that tubing only 3x5 is obtainable locally. Can I use 3x5 or should I order tubing online?