RE:

@Tomson can I ask a huge favour please 🤔 😍

The top caps for the 10mm smooth rod version, is there anyway you can fill the 2 holes in so I don't see them from the top? I like the neat look when they are covered, like the original, and maybe a version of all 3 holes covered?

it would only probably need to be like 2mm? or would you have to stretch it all taller and make it like 5mm to fill the top?.

hard to explain lol so i will include some badly photohopped pics 🤣

thanks man let me know if it's cool:)

the original one is bottom pic

RE: Prusa Bear Mini Mk3s

Hi. Can you use Fusion 360? I left the stepfile just for anyone to change what they like 🙂

RE: Prusa Bear Mini Mk3s

Take the first one 🙂 🙂 🙂

RE: Prusa Bear Mini Mk3s

If you don´t use Fusion 360 i can help you later tonight or tomorrow.

RE: Prusa Bear Mini Mk3s

Hey @Tompson

Its all good buddy, my friend got ti sorted for me 🙂

Ye I must start to learn fusion and not put it off any longer! 😫

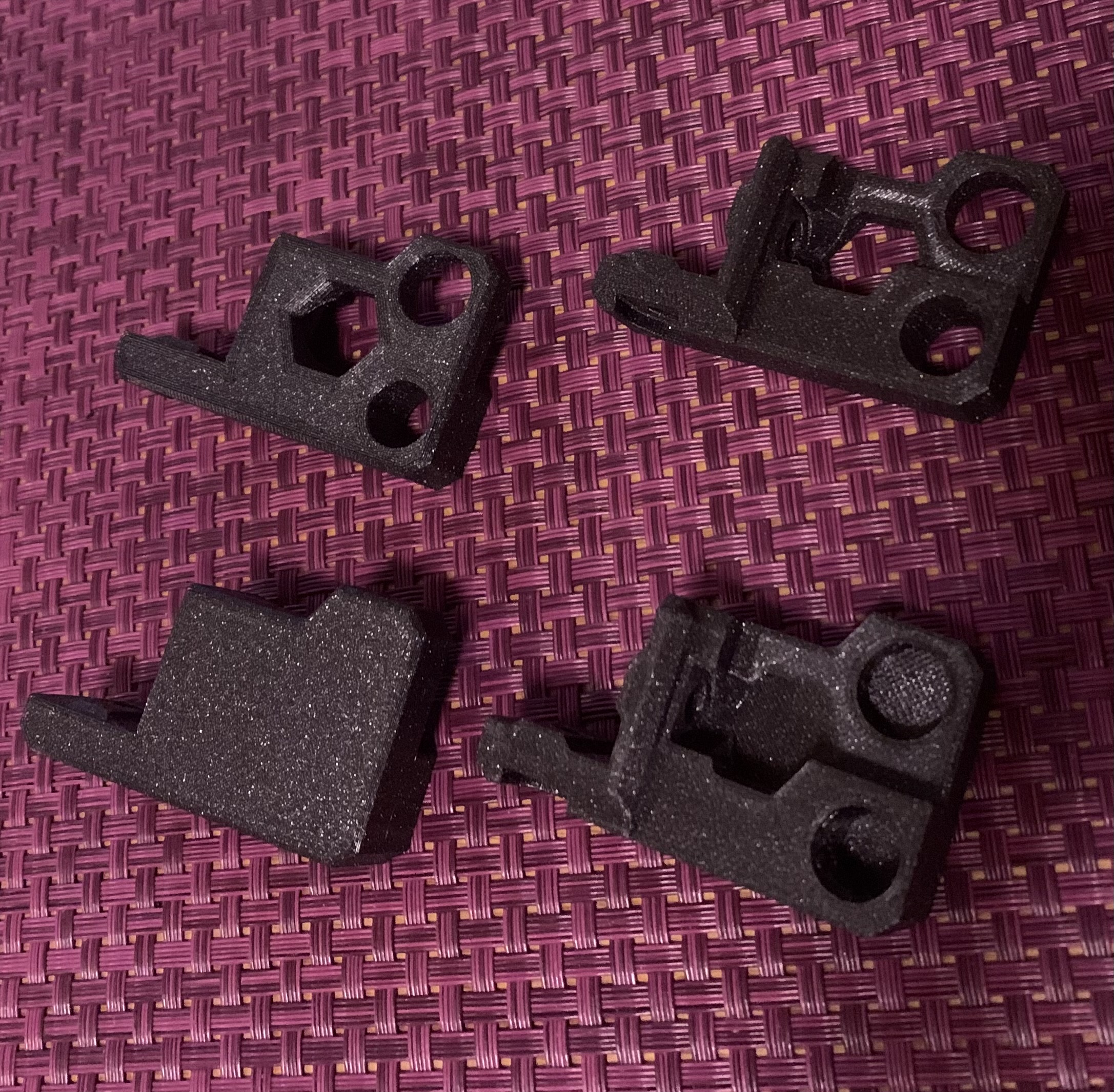

we made the left one the way i wanted it and then just mirrors it to also use for the right side.

I hope they are both the same and just mirrored? 🤣

RE: Prusa Bear Mini Mk3s

@jmac

Hi there,

the teeth idler will give vibration to the belt thats why smooth ones are used.

A teeth idler is perfect if you can synchronise belts but even that over time will strech and you will have a jumping belt.

cheers

RE: Prusa Bear Mini Mk3s

Thanks pear3d.ch, yes i shall just stick with standard then 🙂

no need to reinvent the wheel 😀

RE: Prusa Bear Mini Mk3s

Ok good. Yes they are mirrored. Yes you should get it a try and it´s when you learn Fusion or other cad your printer shines the best 🙂 When you can make something from a thought feels special. Start with a free license and get a feel for it. And the most people i know don´t pay the license version and think it´s ok. I have to many files and 2 computers and also use it every day so for me it´s worth it.

RE: Prusa Bear Mini Mk3s

To be able to create a physical object printed in plastic from a thought is such an amazing thing, what a time we live in. 😍

RE: Prusa Bear Mini Mk3s

Nice. So you gonna cut the rods now i guess. Your Z-height is 350mm right? With BlueRolls frame? Are you planning to use any filament feeder and are you planning to use any topmount spoleholder?

RE: Prusa Bear Mini Mk3s

Hi

Yes I believe they are 350mm, I will cut the rods to suit, and also the top of the lead screw if that requires a little off also, best just having it all in front of me so I can make a plan then as it will all make more sense 😀

Yes a spool holder on top is definitely the plan, maybe something like this: https://www.prusaprinters.org/prints/1019-bear-upgrade-spoolholder-snap-on-for-2040-extrutio not sure on that one though as some people say it snaps... and i would need to remove it if I put into enclosure to print ASA or ABS etc.

maybe a filament feeder is better idea? that is the side mounted ones with the ptfe tube going to direct drive head right?

😀

RE: Prusa Bear Mini Mk3s

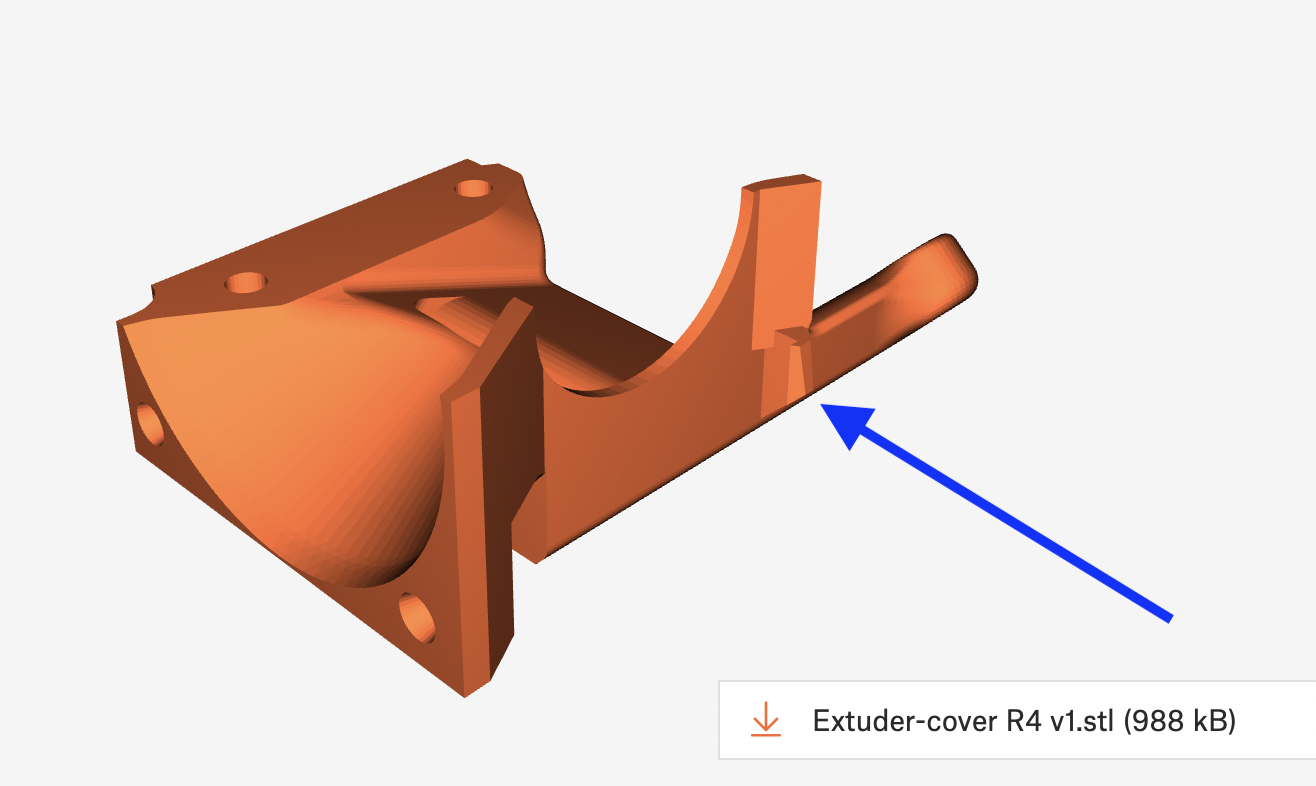

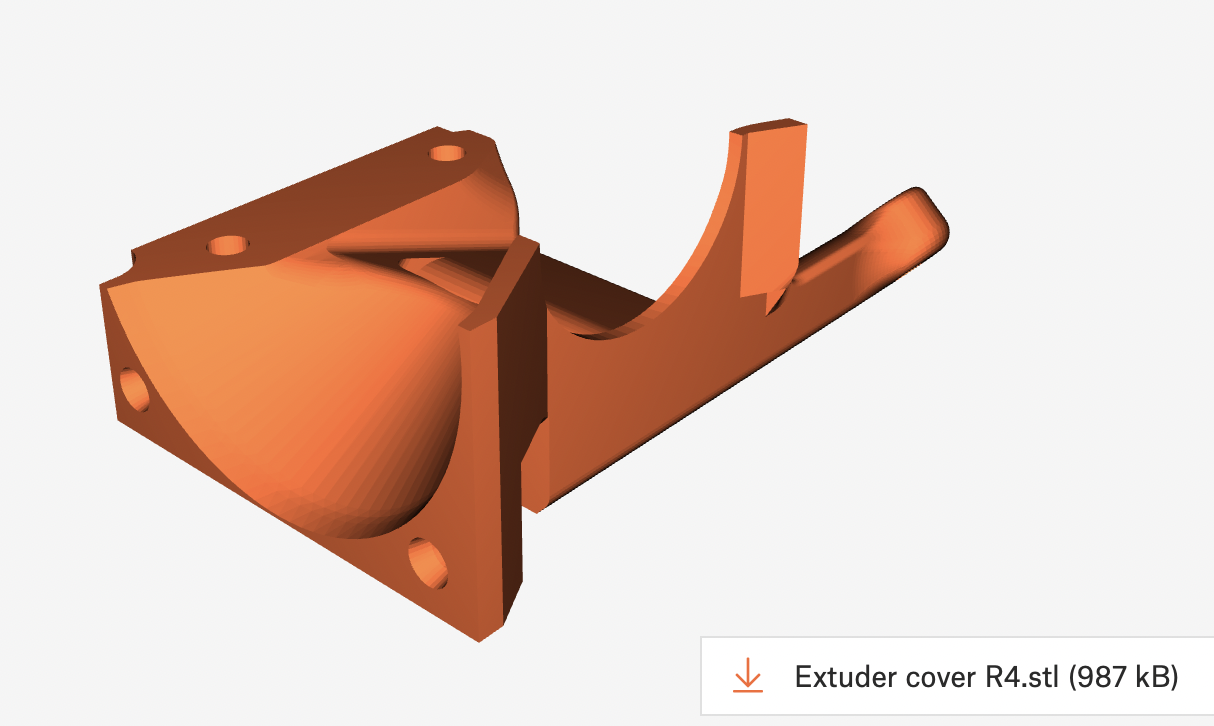

Oh yes the little hook to hold up the shroud 🙂 But i belive that was older version than the one i thought it was. You see that why it´s so important to keep the library correct the hole time 🙂 I guess i learning by my mistakes in time 🙂

Yes you can have all kind of filament feeder. I have 2 extra one the side in the ledlight coming from under the countertop and i guess you can use it if you don´t print to high. That was the reason i kept the MK3 height on Z-axis. But you can always use direct mount ptfe on the extruder i see many people use. I think it depends on how often you change color. I tend to have one black PETG on the left side bec. i use that often and for me it feels easier to change color if the extruder is "free" without any tubing connected. It´s no wrong or right just what feels best for you.

RE:

Hey @tompson

I managed to get the part printed this time, slowed down the speed and made it 100% infill. but man it is VERYYYYY brittle, i'm scared to touch it lol, it is just about to snap lol

I don't know the setup up but is there a way that you could make that bit like double the thickness so its like the fin on the other side?

Or would it get in the way of something? it definitely needs to be more sturdy 🤣

It also printed very hairy and string as no matter what way I select for seam it adds seems to that bit.

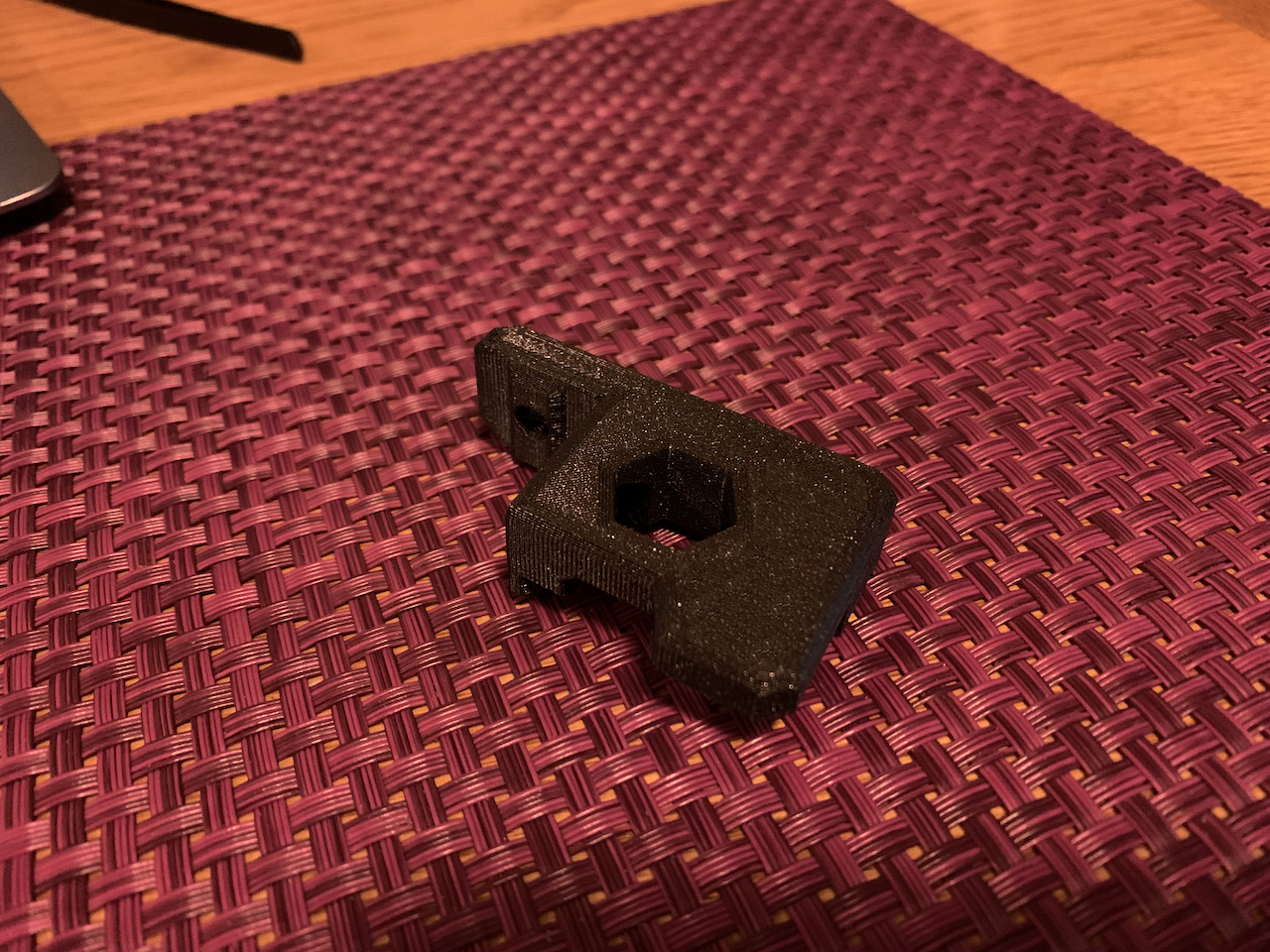

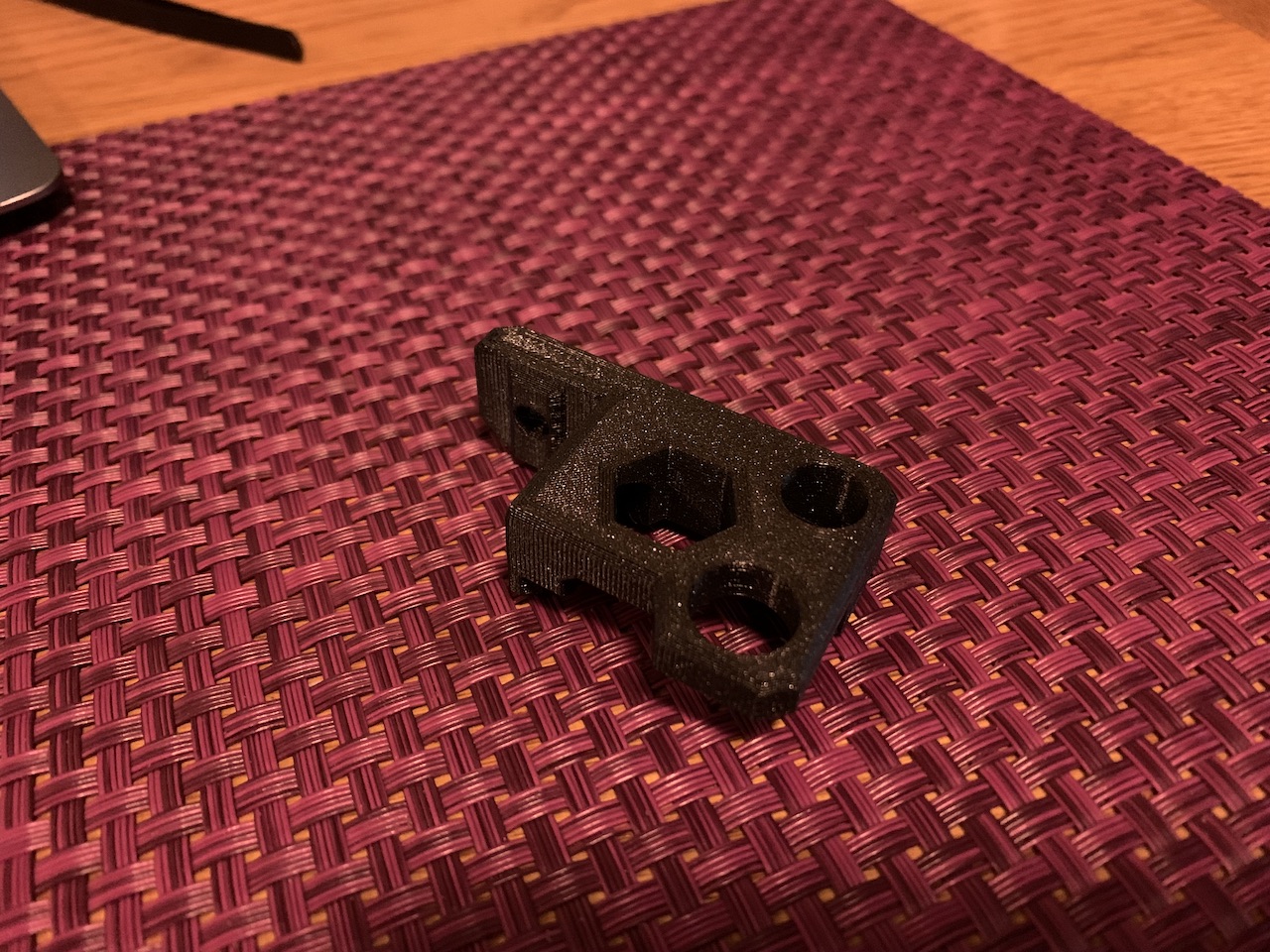

here is some pics 🙂

here it is printed then cleaned of hairs

Here it is from the side on, very thin:

is it possible you can make it thicker and stronger like the other side? sturdier wall? kinda like this: ?

RE: Prusa Bear Mini Mk3s

Hi. Do you have a OEM Prusa or a clone? You said before you had problem to print with PETG. What layer height do you use? I printed that part 4perimeter 0,2layer and 15% infill default settings and i can promise you that piece is very strong i never broke it on any of my printers. Of course i can help you if that is your only problem but i think you have some other issue to take care of first. The only reason I don´t use it now is because I use the new Hurricane now. Do you have any other PETG filament to try with in case something is bad with that specific spole. I´m not the best guy to ask why a print look bad or what settings to change to change the outcome.

That is one big reason i only have OEM Prusas (not OEM per se but you understand what I mean) to be able to print almost everything with standard settings without any issue. I´m sure you can finetune it to get even better result but for me it´s enough.

RE:

Hi

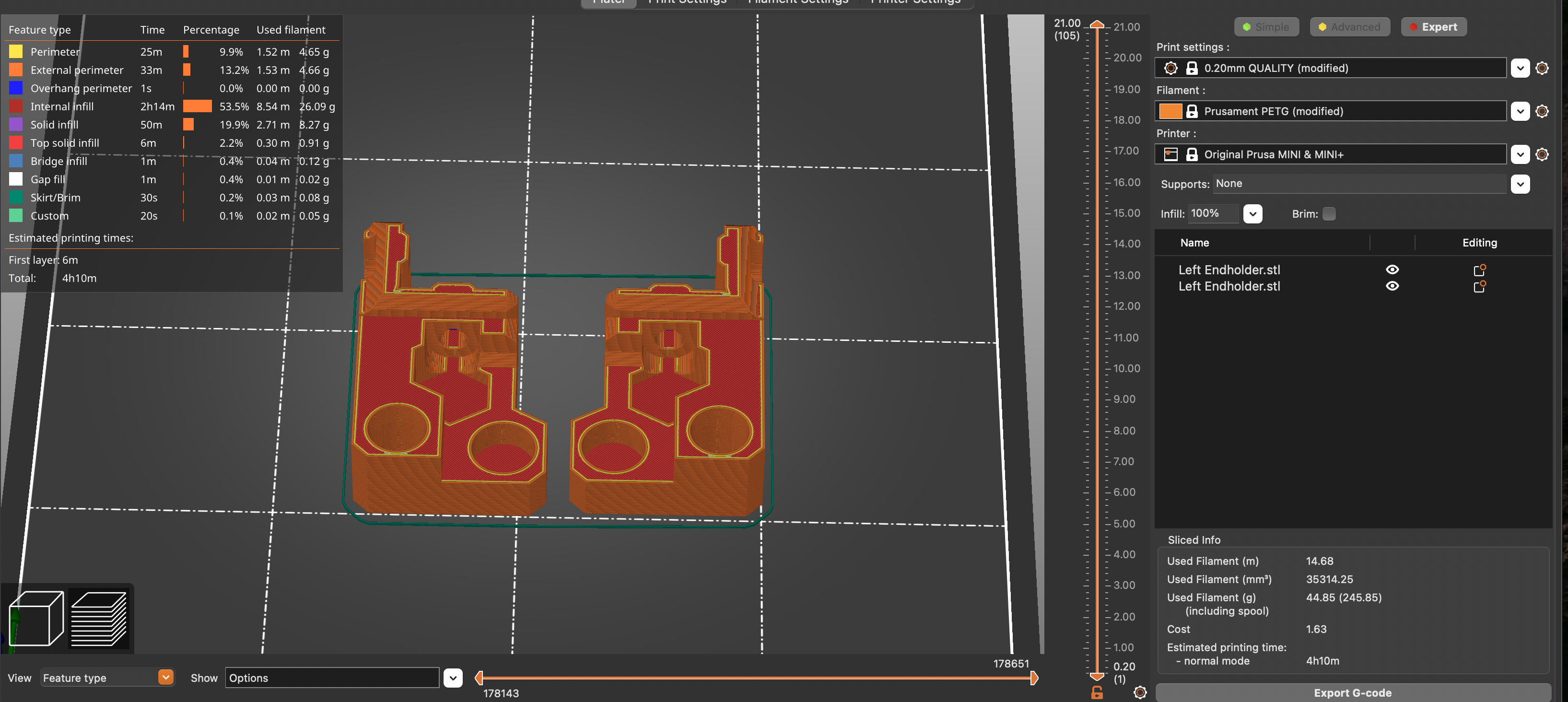

Yes I was having bad issues with petg on the mini, it actually seems to be a little better now and this is how all the bear parts are getting printed.

It is a OEM mini+ bought from prusa, The petg i use is fine, prints fine, and it has been in a food hydrator, it definitely is not a filament issue, so most likely some wrong setting on my mini, just strange that every other bear part prints perfectly for me so far 🤔 just this one bit.

like i said it was stringy and does have a seam on it , so what could cause issue there? retraction or something? I wouldn't know what to change it to to make it better 😫

not sure what to try, third print of it now lol, i guess i will try 4 perim, 15 % infill and 0.2 like you did and see how it looks.

RE: Prusa Bear Mini Mk3s

my mini does sometime make a mess right after seams 🤔

I have never been able to find help online and when i spoke to pruse they just said do belts or send it back.. not much use there.

RE: Prusa Bear Mini Mk3s

Is it on the seams? what seam do you use? When i started printing i almost every time use random. But that did´nt look so nice specially if it was something round. Now i often use painted seams so i can choose exactly where i want it.