RE: Prusa Bear Mini Mk3s

It's pretty difficult to search in this thread.

Thanks for the tip, but this hotend (E3d V6) has been in my Mini for quite some time already, with excellent results. But not that good anymore.

Maybe i should take the whole thing apart again.

It's not as easy as the Mini bowden version though...

There was someone on this thread, 2-3 pages back that had some issues with a new E3D V6 hotend, he managed to fix it and he gave some details on how he fixed it ( https://forum.prusa3d.com/forum/postid/608270/) maybe you have a similar issue?

RE: Prusa Bear Mini Mk3s

Judging by the corner bulging, your Linear Advance might be a bit too low. Try this guide: https://teachingtechyt.github.io/calibration.html#linadv . Maybe some of the vertical surface artifacts will also be solved?

Those surface artifacts can be caused by a number of things, including extruder. You could also check this out

Maybe it helps.

RE: Prusa Bear Mini Mk3s

Hello Guys,

Its been a while since I didn't participate so i have some news there is new profile you can download it from printables: https://www.printables.com/model/37939-prusa-mini-mk3s-bear-ultra-upgraded the file is pear3d.ch.ini.

In order to use these settings i suggest you have firmware 4.3.3 or later where you go to HW Setup push the knob up until the menu appears change the e steps to 140, save and restart.

Cheers and enjoy you Smoki Bear mini beasts.

RE: Prusa Bear Mini Mk3s

PS.

You can also use the full length of Z height now in the menu HW setup change the height where you like it and it will calibrate and all the stuff.

Being fast here, but i have an eye on you guys 😀

Cheers

RE: Prusa Bear Mini Mk3s

Good to hear from you, we've missed you Buddy😎

RE: Prusa Bear Mini Mk3s

I totally forgot about this. I already took the hotend apart. Didn't help much.

I took a look at the gcode settings for filament, but there is still the old printer defined. This means no liniair adv is actually used.

Will do a test with the Mk3 lin adv gcode to see if this will give more insight.

Judging by the corner bulging, your Linear Advance might be a bit too low. Try this guide: https://teachingtechyt.github.io/calibration.html#linadv . Maybe some of the vertical surface artifacts will also be solved?

Those surface artifacts can be caused by a number of things, including extruder. You could also check this out

Maybe it helps.

RE:

Hi there @rinkel

Can you give it a try with the new settings i'v uploaded and check if its doing any better?

Its using the MK3s linear advance 😉

Cheers

RE: Prusa Bear Mini Mk3s

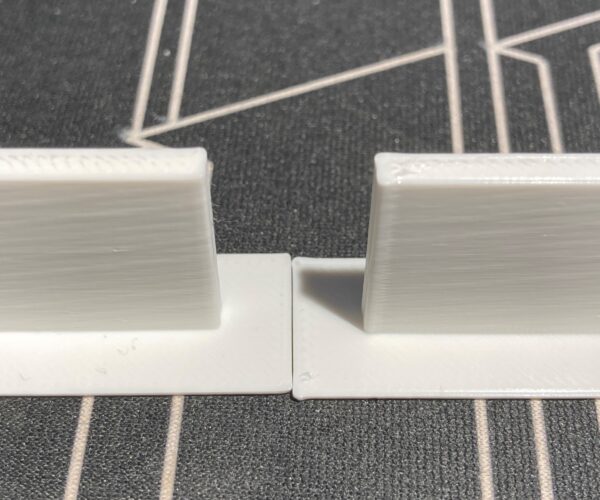

Got some prints.

I got the feeling it's the extruder

I see the corners there its overshooting, 100% if not designed that way its linear advance, now for the wall artifact there must be something else i'll let you check Adrians post cheers

RE:

Thanks! Will give it a try!

I redid the liniair advance process and tried a few. It did help a tiny bit, but not too much.

The liniair adv setting is done in the filament settings, not in printer settings. Pretty sure the filement setting will override.

The overshoot is a bit of seam which i drew there.

I'm affraid i have a case of github #602 ...

Got some prints.

I got the feeling it's the extruder

I see the corners there its overshooting, 100% if not designed that way its linear advance, now for the wall artifact there must be something else i'll let you check Adrians post cheers

RE: Prusa Bear Mini Mk3s

You could also try other filament? Maybe there's something wrong with the current one?

RE: Prusa Bear Mini Mk3s

Unfortunately, the new profile gives me alot of underextrusion. Lots of gaps.

Got some prints.

I got the feeling it's the extruder

I see the corners there its overshooting, 100% if not designed that way its linear advance, now for the wall artifact there must be something else i'll let you check Adrians post cheers

RE: Prusa Bear Mini Mk3s

Are the gaps on the horizontal suface? Gaps along the perimeter?

RE:

That's linear advance 100%. I struggled with that for 2 days :))). Make sure it's something like k0.05 or something similar. Also check filament overrides, remove those conditions with the model and leave just the k value

RE: Prusa Bear Mini Mk3s

Thanks!

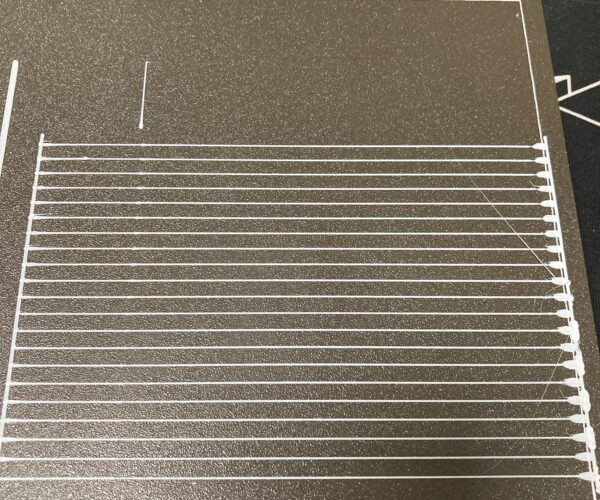

I did the Linear advance test for the MK3, as you can see it's missing the values, but i compared to the picture on the manual.

I now have only M900 K0.01 in the filament settings.

I tested with quite a few ranging from 0.01 to 0.05

But you say that this underextrusion is related?

That's linear advance 100%. I struggled with that for 2 days :))). Make sure it's something like k0.05 or something similar. Also check filament overrides, remove those conditions with the model and leave just the k value

RE:

Yes, I had the exact same issue because I started from standard mini profile. Underextrusion should be vizible on all lines, it would appear as gaps along the lines.

Linear advance tries to compenate for the pressure that builds up in the hotend (and bowden tube) that would appear as overextrusion whenever the toolhead decelerates usually when changing direction - that's why you see it where the infill stops and starts, and around the corners.

By default, Prusa Mini has a big K value due to the bowden tube that acts as a spring/buffer, the leftover pressure in the tube would be sufficient for filling the gaps.

Because you have a direct drive now, the residual pressure is much less due to shorter filament path from the extruder to the hotend, so you need a small K value. This K value can vary slightly depending on the filament type and hotend/extruder (I have a Revo with a Sherpa mini extruder and k0.05 is fine for me, at .4mm nozzle for PLA), nozzle size also impacts the K value.

The problem for me was that I forgot to change filament overrides and I scratched my head for about 2 days until I remebered to check that:))

Play with the K value (and maybe flow-rate, by default is 95%) until you get what you want.

RE: Prusa Bear Mini Mk3s

Ah yes, same thing happened here. That's gone now.

I managed to get Pear3D's new profile to work. I think i was missing any LA setting.

I have tried quite a few LA settings, removed the big "IF" from the filament setting and use a hardcoded M900 K0.05

It is a bit better, but not much.

At least the bulges on the corners are gone by a higher K.

Now trying same print with K0.06. Will just be trying with increasing numbers.

(Will cost me my PLA spool though, but this is the cheaper Hatchbox, which prints nice on the mini)

I thought 0.02 looked best, but hard to read those line.