New PID values

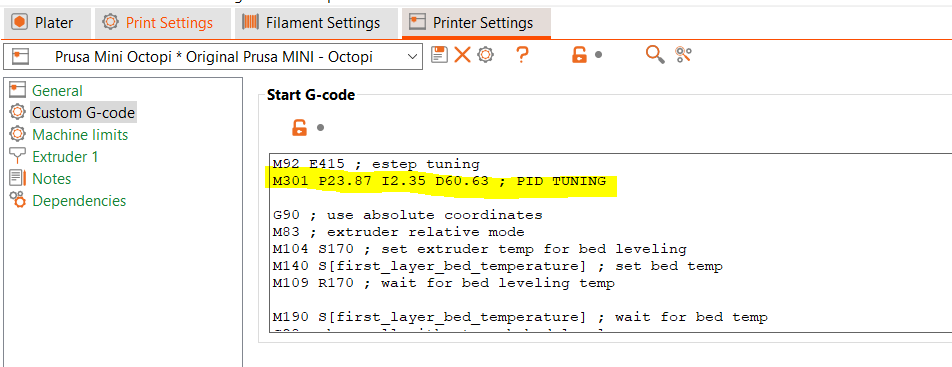

I put a silicone sock on my mini, did the PID autotune in Pronterface and got the new values. Where do I put these values in the start G code in PrusaSlicer and how do they need to be typed? And is there a way to put these values in the firmware so that they are used when doing first layer calibrations, etc?

RE: New PID values

What Mark said. On the Mini, it's not retained across reboots. So the values will not be used for things like the inbuilt first layer calibration unless you run some other print job that uses the startup gcode before. This could be a simple gcode file you run from the usb stick with just the M301 command that you can create with a text editor. Having said that, I don't think PID tuning matters for something simple such as first layer calibration so I wouldn't worry about it.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: New PID values

The Prusa Mini doesn't use Marlin PID but a combination of a custom algorithm and PID:

Due to the support of custom extruders, we received requests from the community to enable Marlin PID in the firmware. We have performed multiple tests using different materials to verify the “Prusa” thermal regulation works correctly on both stock and custom extruders. The results below show clearly that the current algorithm (a feed-forward driving + PID tuning of the steady state) is capable of correct thermal regulation in all tested scenarios including the sudden start of a cooling fan.

Also, the implementation of two regulating algorithms and switching between them creates a risk of a bug or failure, which can possibly lead to printer damage. Moreover, based on the results the default Marlin PID performs worse in some scenarios (e.g. when the cooling fan is suddenly started). Since the provided algorithm works as expected even for custom extruders, we have decided to keep it unchanged.

You can find examples and details here.

RE: New PID values

@lichtjaeger -- Is this to suggest that custom PID tuning is not required regardless of hotend (such as a Prusa mini using a v6 hotend), with or without silicone sock, or any other hotend? Also, if I read your attached link correctly, we are now able to update the mini's esteps and they will be saved to the printer and not require the Before start g-code?

RE: New PID values

@lichtjaeger -- Is this to suggest that custom PID tuning is not required regardless of hotend (such as a Prusa mini using a v6 hotend), with or without silicone sock, or any other hotend? Also, if I read your attached link correctly, we are now able to update the mini's esteps and they will be saved to the printer and not require the Before start g-code?

Jap, you don't need to do PID tuning on the Mini at all. And also yes, you can safely adjust e-steps, bowden length and extruder direction from the settings menu and don't need to adjust the start g-codes.