Mini enclosure height

This will be my first printer and although I was quite enthusiastic when I took the plunge and ordered a Mini two months ago, my enthusiasm has started to wane a bit so I thought I try and keep my interest going for the next two months with a 'build an enclosure' project.

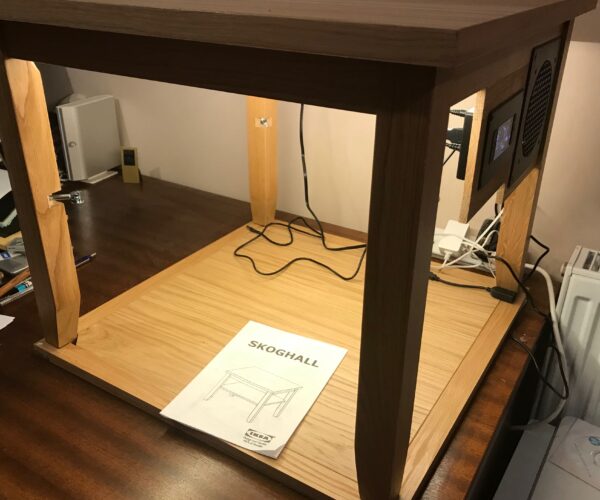

The IKEA Lack seems to be the most popular choice but they're so light / flimsy and there seem to be a lot of vibration issues (planning to have to add a concrete paving slab for stability seems the wrong place to start) so I decided to go for a sturdier coffee table - IKEA's 'Skoghall'. The internal height of the Lack is 40cm, the Skoghall has 42cm and its made from solid wood / veneered MDF / chipboard rather than a paper filled shell so it's more sturdy than the Lack also the shelf (with a bit of oak strip wood go round the edge) makes a good base. I don't need legs as it will sit on a desk.

Unfortunately I can't now draw on the experience of many on the forum and use the hinges and fittings from your Lack designs so I've got to deign my own ... and now I hit a problem - how thick do I make the bottom hinges / spacers and how tall do I make the perspex sides? (can't add a spacer to the top of the legs due to the construction of the table so it's all at the bottom) ... as I said above, the Lack has 40cm clearance, the published height of the Mini is 38cm - not allowing for the Bowden tube and printhead cables - Prusa's advice is to allow 25cm all round clearance ... that would mean raising the Lack 23 cm !! (21cm for my table) so, from your pictures, you've clearly compromised but without a Mini to work from I can't see how much clearance is actually required. On other threads on the forum some have said a height of 44cm is required, some 48cm, and some have said that the Lack is too big for the Mini ... I'm confused (not difficult 🤣).

Could someone lucky enough to have a Mini already, measure the height of the cables / Bowden tubes with the printhead at its closest point to the Z axis please?

Thanks in advance

John

Best Answer by Pete Brown:

On my Mini, with the X axis all the way up, it's 460mm from base to top of the wire loom.

For stability, I keep mine one two pieces of MDF, so that would add another 40mm, apx.

You will need to get to different sides of the Mini to square it all up. Doing that inside an enclosure is a pain. Doing it and then putting the mini in the enclosure will result in messed up axes again. So put it on a couple pieces of super flat MDF and use that as the stable base upon which it sits inside the enclosure, and also what you square things up on outside the enclosure.

This is what I had to do:

Finally, get a USB extension so the USB port is at the front.

Pete

RE: Mini enclosure height

On my Mini, with the X axis all the way up, it's 460mm from base to top of the wire loom.

For stability, I keep mine one two pieces of MDF, so that would add another 40mm, apx.

You will need to get to different sides of the Mini to square it all up. Doing that inside an enclosure is a pain. Doing it and then putting the mini in the enclosure will result in messed up axes again. So put it on a couple pieces of super flat MDF and use that as the stable base upon which it sits inside the enclosure, and also what you square things up on outside the enclosure.

This is what I had to do:

Finally, get a USB extension so the USB port is at the front.

Pete

RE: Mini enclosure height

@pete-b3

Thanks for the measurement ... and the advice. Looks like my hinges/leg supports will be 4cm - a bit bigger than I'd hoped for but I bought the printer for practical, not aesthetic, reasons so whatever works 😕.

I'm using the shelf as a base and that's veneered chipboard so it should be flat - IKEA's build quality is pretty good. I've read your posts on the assembly / troubleshooting thread - 2mm difference in bed height seems like a lot. Like you, I was persuaded by Prusa's reputation to buy this printer and I'd hoped for better ... but it's 2 months away so perhaps their build quality will improve. I inferred from your posts that you're inserting the shims under the feet of the bed, does the base (which I thought was metal) flex that much that shimming under the feet has such an effect? Prusa include rubber (plastic?) feet to stop scratching so perhaps these are the source of the problem. If the Z / X axis assembly is screwed firmly to the base wouldn't washers behind the screws be a better solution?

My plan for the enclosure are not to screw the legs to the base and rely on the weight of the table to keep it in place (it's quite heavy - compared to the Lack) so it will just lift off if all round access is required.

... but no plan survives the first encounter with the enemy ... 🤣

John

RE: Mini enclosure height

@pete-b3

re: bed levelling - from https://help.prusa3d.com/en/article/bed-level-correction_2267 ...

"... the Bed Level Correction is an important feature designed to allow users to compensate for even the slightest imperfections in the first layer. It allows to virtually raise or lower the heatbed on the Left, Right, Front and Back sides, essentially enabling you to have a different Live-Z value on each of the four sides of the heatbed ..."

Your bed levelling comments imply this doesn't work ... that may well be a 'support' issue

John

RE: Mini enclosure height

@pete-b3

re: bed levelling - from https://help.prusa3d.com/en/article/bed-level-correction_2267 ...

"... the Bed Level Correction is an important feature designed to allow users to compensate for even the slightest imperfections in the first layer. It allows to virtually raise or lower the heatbed on the Left, Right, Front and Back sides, essentially enabling you to have a different Live-Z value on each of the four sides of the heatbed ..."

Your bed levelling comments imply this doesn't work ... that may well be a 'support' issue

John

Bed leveling has its limits. You need to get the machine reasonably square, first. Also, bed leveling has no idea about axis skew.

I put the shims between the aluminum extrusion that supports the Y axis, and the 3d printed electronics box. There's a "common problems" thread where the author includes the shim tip and has a graphic so you know what I mean. I shimmed in the same place (the red area)

Pete

RE: Mini enclosure height

@pete-b3

Thanks again for you further explanation - I understand where the shims would go now ... all I need is a mini to experiment on ... but that's in the hands of 'the gods' Prusa 🙄 😀 .

John