RE: Different Hotends

@crawlerin

Ah I just noticed that, looks just like textured PETG. No wonder I couldn't find it in the PM stl files..

RE: Different Hotends

@4nthonylin

I am still using the original revision of the fan shroud you posted and waiting on additional revisions before I re-print. But the shroud is great! And so is my Mosquito. I can print hours using PLA and prints come out visually flawless. I need to spend some time tuning settings, as clearances are a bit tight. But so happy with these upgrades. Thanks for posting the fan, compared to the stock shroud + Mosquito, it definitely makes a difference.

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Different Hotends

I got my mosquito, nervouse to install it but I will get to it today. questin, do you apply the boron nitride paste to the nozzle threads as well? Also what is the process for curing the paste ?

RE: Different Hotends

@kevman

You don't have to, and I suggest you don't. It will prevent you from being able to do cold nozzle swaps. Which is super nice in my opinion and a key feature of the Mosquito.

As for drying, I suggest you assemble your mount and Mosquito before inserting the temps sensor and heater core. They will slip and slide until the paste is dry. What I did was allowed a 1hr air dry, then ran a print which very quickly dried out the rest.

Good luck!

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/

RE: Different Hotends

@benji Glad everything is working well for you 🙂

@kevman Best of luck installing it! Just treat the heater cartridge and thermistor wires with care. As @benji said, I don't apply to the threads of the nozzle either and has been working fine. 30minutes air dry and a xyz calibration cube did the trick for me. Once you have everything installed, be sure to follow the steps at the bottom of the summary: https://www.prusaprinters.org/prints/36643-prusa-mini-mosquito-mount

The offset is important for the prime line and pid calibration is optional to prevent temperature overshoot. Also the first layer calibration won't work super well since the first prime line will be off the bed. What you can do is after mesh bed levelling, pull the sheet ~6mm out so the prime line is on the bed or you can just let it fall.

RE: Different Hotends

Thank you for your valuable contributions and guidance. I do have one more question, I printed malcom's open face mount, which calls for a 17mm PTFE tube , where as I have see 15.5 mm tube on the orignal mount by 4thony. I assume I go with 17 ?

RE: Different Hotends

If you are using @malcmcm version then you should follow his suggestion which is 17mm. In my opinion the length isn't super critical since the brass fitting will compress the tube and it only helps guide it a short distance. Also mosquito is an all-metal hotend unlike the existing mosquito where the ptfe slides further into the hotend.

RE: Different Hotends

Ya the exact length isn't critical as long as it's good enough to guide the filament into the mosquito. I measured 17mm on mine as the brass coupler sits a little proud of the mosquito mount. I didnt want the threads of the coupler intersecting the m2.5 screw heads.

RE: Different Hotends

Hey all I' am in flight on this upgrade. Can I reuse all the original prusa heatsink screws ? I think one might have needed to be longer IIRC.

how tight should the brass fitting be against the mount ? I have probably 2mm between the hex and the mount, I don't want ot push it tighter if not neccesary, it seems pretty snug and secure.

RE: Different Hotends

@kevman

There should be a small gap between the brass and mount, don't force it if it feels snug, should be ok.

I had to use a 25mm screw to attach the lower right corner of the fan to the mount. One from Prusa was a bit too short. Other than that I think you should be able to re-use all original screws.

RE: Different Hotends

@kevman I also had to use a slightly longer screw too as well, you can actually probably get away without it for now, but if you can get a M3x25mm or 30mm long screw that would be ideal. I'll make a note of that, sorry didn't get to it 😐

Also just in general, an assortment of m3 screws are super helpful too. Something like this: https://www.amazon.com/VIGRUE-M2-M3-M4-1080PCS-Stainless-Screws-Socket/dp/B071KBVZVV/ref=sr_1_3?dchild=1&keywords=m3+assortment&qid=1596248033&sr=8-3

Other than the short screw, have you been able to get everything else setup?

RE: Different Hotends

Thanks for the input all. So here is my update.

I found that the screw that comes from behind that is covered by the exhaust fan was just short, so I replaced it with a longer one.

I had a mini nightmare with the boron paste , I was bit to enthusiastic and it came out flying everywhere, it mostly got into the prusa mini fan. luckily I covered the heated bed and it that was saved from the mess. After cursing myself and cleaning the mess I have the thermistor and heater coated and drying in the hot end. I ended up getting a silcon sock, so I secured that onto the wires prior to putting the paste on so I can slide it on that once I have the nozzle in and don't need to remove the thermistor or nozzle. I'm taking a pause break for now and will let this dry overnight. Hoping to get it started and testing tomorrow.

RE: Different Hotends

got my first sucessful print with the new hotend! very pleased so far, but it was a small one. If somoen can suggest a good test model I'd love to try one.

Also, I know this is the command for PID tuning : M303 C8 D S200

But is there a way to change the default values to stick once you get the values ?

RE: Different Hotends

I'm able to set the PID values with this command, but does this make it permanent ? do I need to run M500 ?

M301 P22.49 I1.97 D64.33

RE: Different Hotends

looks like m301 is not taking my pid values, I do a m501 to check and it shows different values. Any ideas ?

RE: Different Hotends

I don't think M500 works on the Mini but I'm not 100% sure. I put the new PID in the start g-code in slicer, doesn't save to EEPROM and wont come up with M501 slicer individual prints should have the correct values.

RE: Different Hotends

@kevman glad to see everything is working. I would say the biggest pro would be the bump in reliability over the stock hotend. Benchies, calicats, and calibration cubes are good prints to try out. Just continue printing as you would and you should not see any of the under-extrusion or heat creep issues 🙂

M500 doesn't work so I just have it set the start-gcode. M501 loads from eeprom, and M301 only sets the in memory values. You can use M503 to confirm that M301 is correct. Everytime you restart the printer, the values will be reset as shown in M501.

RE: Different Hotends

@4nthonylin

Thanks! I did to the M503 and the values I put in for PID were not accepted. Tehy were close but not the exact. So far it seems nominal as everything is working good and temp is stable.

<code>

M301 P22.49 I1.97 D64.33

Send: M503

Recv: echo: G21 ; Units in mm (mm)

Recv:

Recv: echo:Filament settings: Disabled

Recv: echo: M200 D1.75

Recv: echo: M200 D0

Recv: echo:Steps per unit:

Recv: echo: M92 X100.00 Y100.00 Z400.00 E325.00

Recv: echo:Maximum feedrates (units/s):

Recv: echo: M203 X180.00 Y180.00 Z12.00 E80.00

Recv: echo:Maximum Acceleration (units/s2):

Recv: echo: M201 X1250.00 Y1250.00 Z400.00 E4000.00

Recv: echo:Acceleration (units/s2): P<print_accel> R<retract_accel> T<travel_accel>

Recv: echo: M204 P1250.00 R1250.00 T1250.00

Recv: echo:Advanced: B<min_segment_time_us> S<min_feedrate> T<min_travel_feedrate> J<junc_dev>

Recv: echo: M205 B20000.00 S0.00 T0.00 J0.02

Recv: echo:Home offset:

Recv: echo: M206 X0.00 Y0.00 Z0.00

Recv: echo:Auto Bed Leveling:

Recv: echo: M420 S0 Z0.00

Recv: echo:PID settings:

Recv: echo: M301 P18.00 I1.84 D43.91

</code>

RE: Different Hotends

So my prints are workign great so far, I started a 2.5 hour one this moring, no clicking or extrusion issues! fingers crossed. I'm wondering if I should print the x-carriage mod next ? what advantage would it provide if my prints good so far ? I am not opposed to it, I am wary about changing that part but I am sure it will be ok.

RE: Different Hotends

@kevman

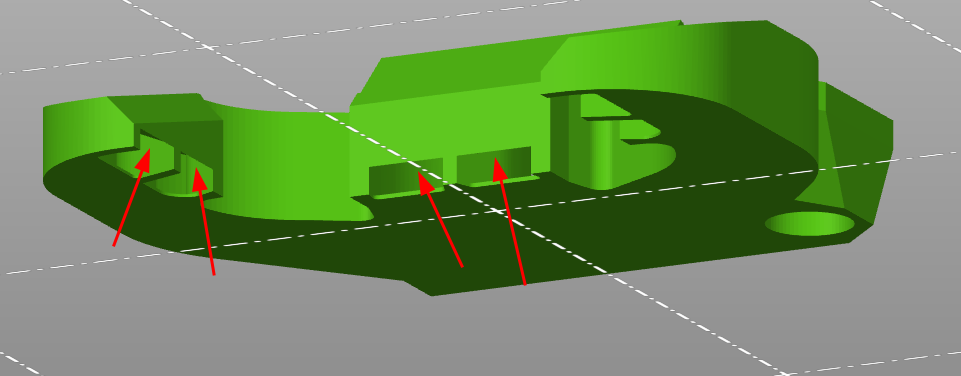

The x-carriage mod is part of the fan shroud mod. Some advantages are better overhangs, better details on small parts, and just cleaner prints altogether. I have prints from both and can say that it does make a visible difference.

Here are some examples of where I saw the most improvement:

Prusa Mini Silicone Bed Leveling Mod: https://bbbenji.github.io/PMSBLM/