Cooperative Prusa Mini

Hello All,

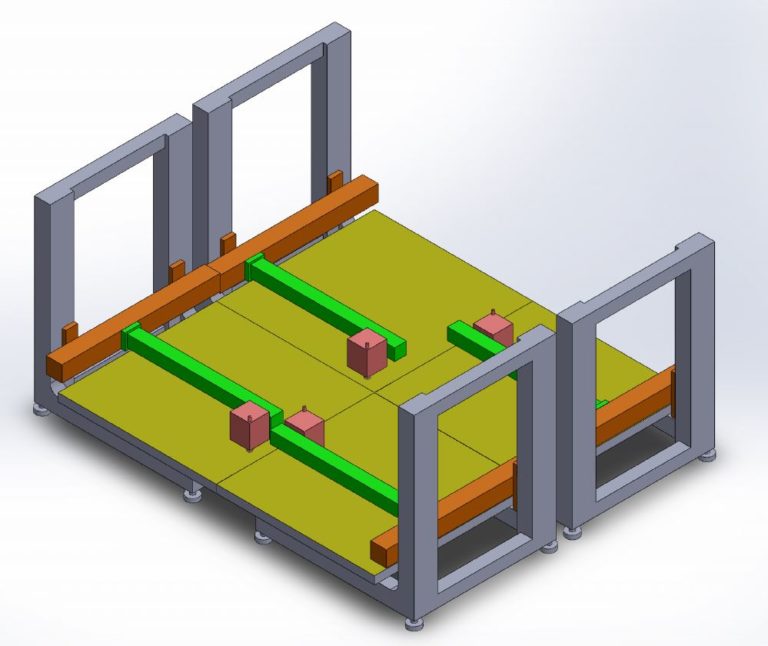

I had a concept to make adjustments for "Cantiliever" printers to allow two printers to work together. I wrote an article about it sometime ago and did a mod on a Ender 2 at the time (it no longer available in market). I think this solution is more suitable for the Prusa mini.

It could allow faster printing and at least , four printers can print on the same build plate.

This is the link for the article on my blog : http://www.ramifications.de/2018/07/07/cooperative-3d-printers/

I also made a "Not so good" video about it, but did not have the time to continue on the project.

Let me know what you think.

Is anyone willing and able to take on this project ? I am putting it online as an Opensource concept.

Do you think Prusa engineer would be interested in it ?

RE: Cooperative Prusa Mini

Idea looks good, but I see many pitfalls. For example, one hotbed means, that all 4 have to be extremely synchronized for Y movement in every possible way with frequent pause after each Y movement. Slower, like dirty belt on X movement could cause that there will be desynchronization by few nanoseconds, which means visible corruption after few hours of printing using one hotbed. And if you want to build a big object using all 4, the synchronization among printers would be a nightmare as they may crash to each other or the corners/edges of printers may not fit properly together.

When doing multi-clone objects, I would say, is better to put on X movement trolley 2 and more extruding platforms apart by some specific distance, of course larger hotbed. Mini is not good for this kind of action as it is built as a standalone printer for a farm of printers.

RE: Cooperative Prusa Mini

@kiwo

Thank you for the comment.

The first step is to fix the hot bed by modding the printer. The structure carrying the nozzle will move along Y. The bed is fixed.

I think synchronization can be done by having one controller running several printers, or connecting the controllers.

The big challenge i think would be to have a dedicated slicing script that can generate the g-code for "Collaborative" printers.