RE: I'm smartifying my Prusa MK4 enclosure!

The project is finished!

You are welcome to use the tutorial to build your own smart enclosure. It looks amazing and it functions perfectly — lighting and filtration is fully automatic.

RE: I'm smartifying my Prusa MK4 enclosure!

Hi @RuddO,

nice work!!!

Can I assume, that you are able to control the rpm of the original Prusa Fan, shipped with the Advanced filtration system??

This was also my Idea, and my assumption was, that the Fan connector is Intel Fan controller compatible, that means:

Pin 1: GND (white line on the black ribbon cable)

Pin2: 24VDC,

Pin3: Tach signal - probably an Open collector output, so you need to use an Pullup resistor around 10k to 3.3 V.

Pin4: PWM - base freq. 25kHz, Signal lower than 0.8V = Logic low, higher 2.5V is logic high, max input 5v.

based on that I did interfacing the Fan to an Raspberry Pi 4, the result is that I can now use that Raspberry pi as Chamber heate, cause the fan burned the BCM and now the BCM is a large Resistor. (Sad also was, that it was a 8GB Pi4...)

But at that point I thought the PI 4 gone defective randomly, so connected to an Pi3, setup 25kHz PWM with 3.3V, directly after power up tha fan runs at 100%. Okay, PWM fans runs at 100% as long as they didn`t receive the PWM freq. But after trying to control, by PWM, the Fan kees 100%..

Finally the fan burns the PWM Gpio, it stays on 3V and can´t be controlled by any command.

I measured the fan cable, if there is an short circut, to gnd or even 24V but didnt find anything.

Had I only bad luck and got a Fan that isn`t okay, or did. I any mistake?

Greets Thorsten

My Printables models including Nextruder improvements: https://www.printables.com/@ThorstenLach_1801966

RE:

That's correct! The code and wiring both support controlling fan speed and the fan is by default working in low / medium / high. I did some math to compute adequate speeds for these three levels. Furthermore, the fan (when set in auto mode) also varies the speed of the fan according to the level of pollution, ensuring quiet operation unless strictly necessary, and totally silent operation when the air inside the enclosure is clean enough.

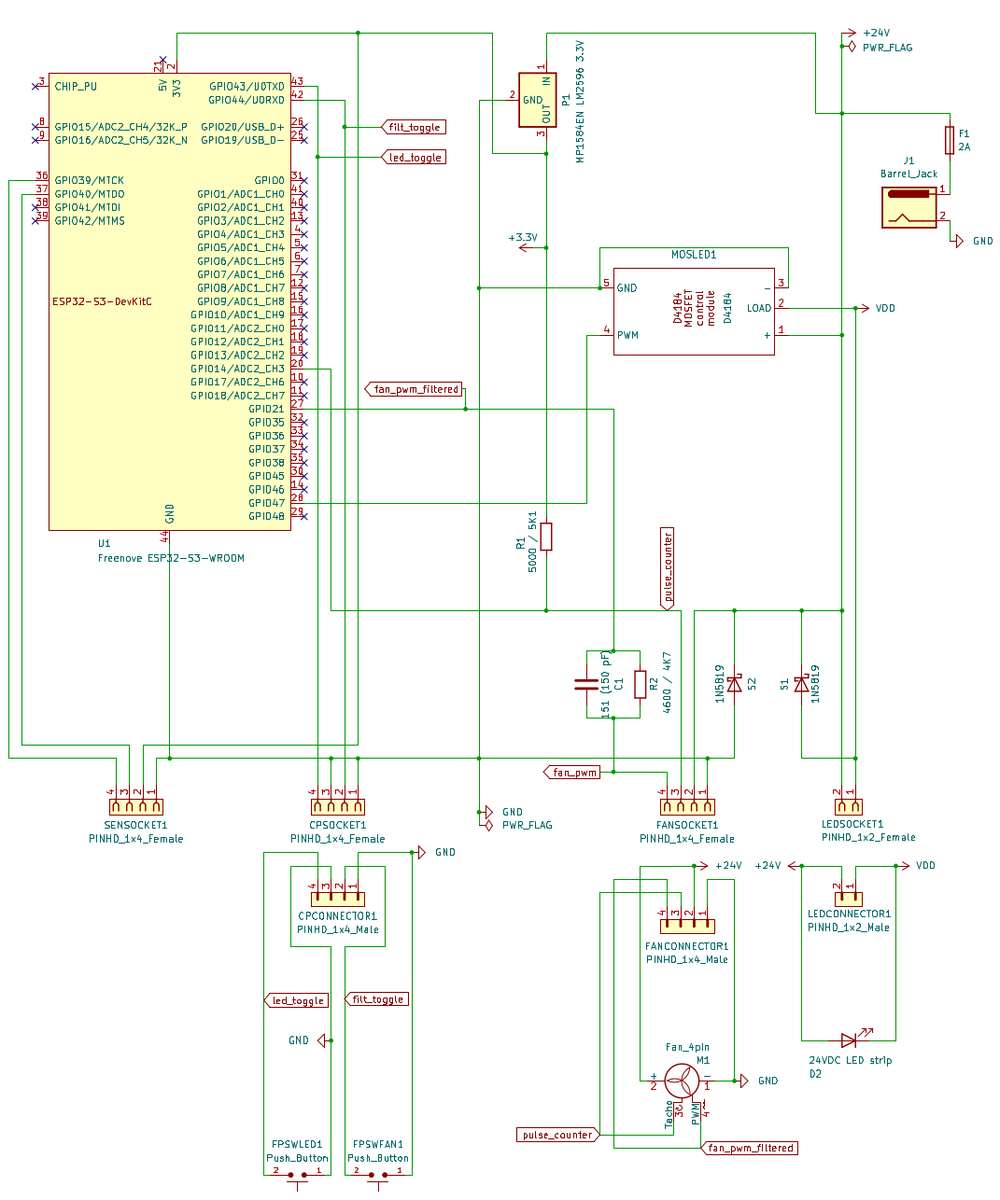

Fan pin 4 is PWM, and pin 3 is tach. In my design, GPIO used to drive PWM is filtered using a 4.7K resistor and a 150 pF cap — if you don't do this, you fry your board which is what happened to you. GPIO to read RPM I think I used the internal pullup of the ESP to get a stable signal. You'd have to check the code.

RE:

@Ruddo question if you could provide graphs from the BME sensor during and after print with and without filtration ( with the time span until the levels are back to the same values as prior print).

I just want to compare it to the particulate sensor, because from my observations particulate sensor is much better at showing what's inside the enclosure than any other sensor that I have.

See my GitHub and printables.com for some 3d stuff that you may like.

RE:

Happy to!

When printing ABS or ASA, you should expect something like this. The first photo is with filtration turned off (to prevent warping). The second is with automatic filtration on (forgive the granularity of the statistics in this case, the short term statistics have been wiped from the database).

As you can see, filtration is effective against stuff that emits VOCs. When automatic filtration is on, the fan spins up at speed and cleans the air effectively, whereas when filtration is off, VOCs drop off only when the print is done and they leak out of the enclosure.

Particulate sensors are way more useful when you're printing PLA or PETG.

Fortunately, any 3.3 volt powered sensor (compatible with ESPHome) that supports particulate sensing can be connected, either instead of the BME688, or in parallel to the BME688, and that will almost certainly just work. The automatic fan speed code does not yet take into account PM volume / count — currently the code just takes into account the Static IAQ value, the thresholds of which you can configure through the Home Assistant GUI — but the code could very trivially be adapted for that purpose.

It might be wise to make a separate casing for the particulate sensor, or to modify the casing where the BME688 slots in to have another slot for the specific sensor you choose for your project.

RE: I'm smartifying my Prusa MK4 enclosure!

Excellent info, thank you very much!

See my GitHub and printables.com for some 3d stuff that you may like.

RE: I'm smartifying my Prusa MK4 enclosure!

@RuddO this is an awesome project and I'm really into it.

My problem is that I don't have knowledge in soldering, wiring and so on. I'm a mechanical engineer and usually I stay away from wires 🙂

Do you think it is possible for me to do this project with home assistant? I mean getting the components, wiring... or do you think I should stay away as long as I don't have a clue?

Thanks and best regards

Dennis