Why is the PrusaSlicer Support so bad?

Hi,

I'm a Prusa Mini.

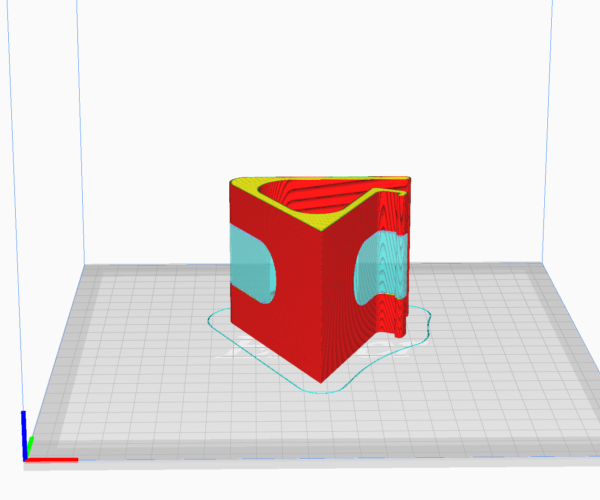

I have no luck with support in the official PrusaSlicer. Its always stucks a way to hard and the Slicer generates it on areas where its not necessary. Its also a way to wide and also stucks to normal walls. If I change "Pattern Spacing" to Zero it looks better, but its also very massiv and stucks even more. In Cura its better by far!!!

I'm using the default profiles with PETG.

Is there any way to optimize this?

Please help

RE: Why is the PrusaSlicer Support so bad?

Here are the settings I use for removable supports:

- Contact Z distance: 0.25mm

- Pattern spacing: 3mm

- Interface layer: 3

- Interface pattern spacing: 0.2mm

- Interface loops: OFF

- XY separation: 75%

- Don't support bridges: ON

Using these settings, supports remove easily and I can get reasonable results even with fine miniatures.

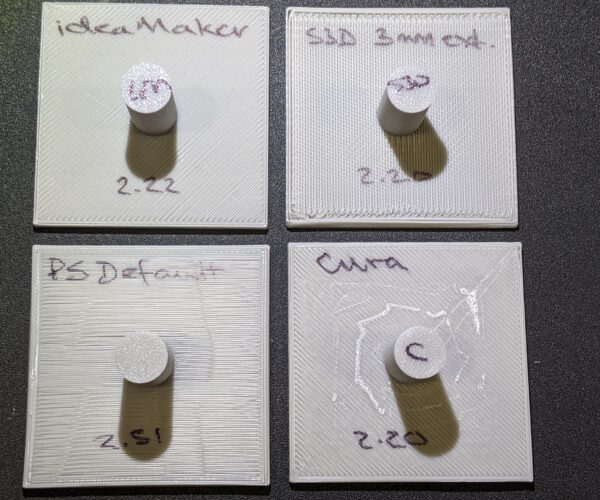

Unfortunately, PrusaSlicer does not generate nice undersides for supported surfaces. This is a weakness that simply hasn't been addressed by the development team since forking away from Slic3r. I use ideaMaker in situation where I need cleaner undersides for supported surface (e.g. surfaces that need to be glued together or reasonably dimensionally accurate).

Here's a quick comparison of the underside of supported surfaces and resulting 2mm top surface thickness using (left-to-right, top-to-bottom) ideaMaker, Simplify 3D, PrusaSlicer and Cura:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Why is the PrusaSlicer Support so bad?

Thanks.

I will test these settings. But why is there so much support on the walls, too? For me its makes no sense, to wast material and its also makes the walls looks ugly.

The very small support on cura works perfect.

RE: Why is the PrusaSlicer Support so bad?

[...] But why is there so much support on the walls, too? For me its makes no sense, to wast material and its also makes the walls looks ugly.

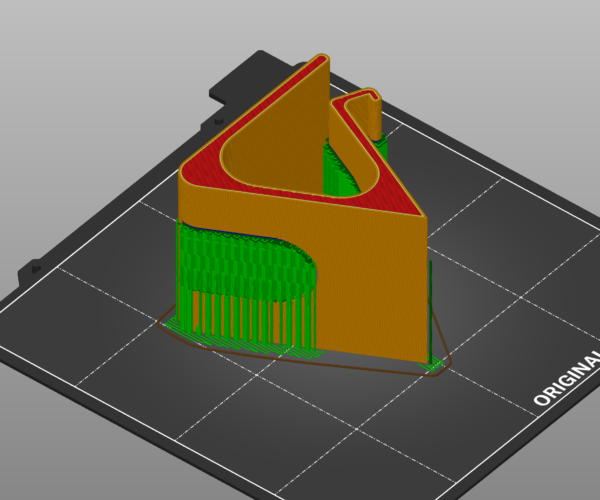

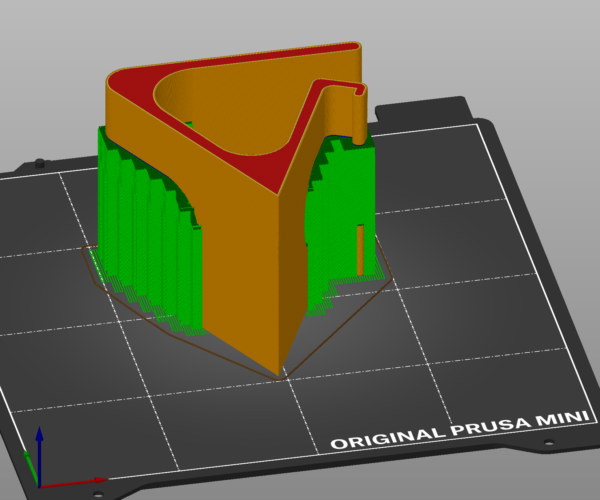

I'm sure it's another part of the legacy code inherited from Slic3r that the development team will look at eventually. Other slicers offer different and often more options. You can get more precise control by selecting where supports will be placed. The new paint-on support feature of the PrusaSlicer 2.3alpha releases may help reduce the amount of support generated. The paint-on approach to custom supports is something unique to PrusaSlicer.

You can reduce the amount of wasted material by specifying a less dense pattern spacing (under Print Settings->Support material->Options for support material and raft).

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Why is the PrusaSlicer Support so bad?

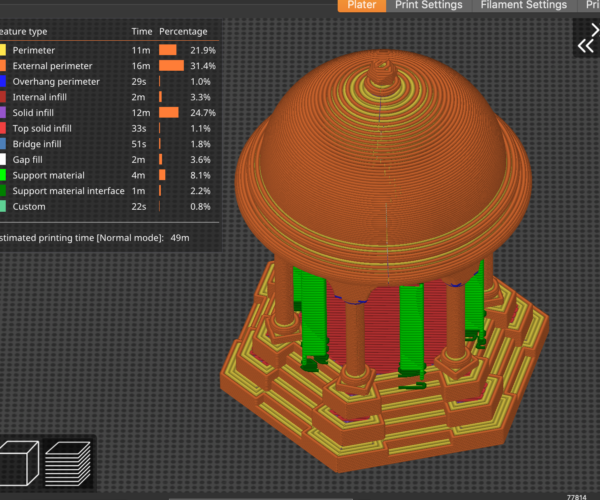

Here's a quick comparison using default automatic support generation in PrusaSlicer:

And smaller paint-on support modifiers using PrusaSlicer 2.3alpha:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Why is the PrusaSlicer Support so bad?

I do agree that Cura, in general, is better for supports, but sometimes PS will surprise you and do a great job with them.

RE: Why is the PrusaSlicer Support so bad?

I'm a big fan of PrusaSlicer but I do hanker for Cura tree supports - not because they do the job (which they do) but they look so cool doing it.

RE: Why is the PrusaSlicer Support so bad?

I use ideaMaker in situation where I need cleaner undersides for supported surface (e.g. surfaces that need to be glued together or reasonably dimensionally accurate).

Bob - I had a look at ideaMaker but stopped at the printer set up as I had no idea what all the values should be. Would you have a set up file or parameters for the Mk3s that you could share, perhaps on your website? many thanks

RE: Why is the PrusaSlicer Support so bad?

Bob - I had a look at ideaMaker but stopped at the printer set up as I had no idea what all the values should be. Would you have a set up file or parameters for the Mk3s that you could share, perhaps on your website? many thanks

ideaMaker is a little quirky to get started with if you don't have a printer profile. It's also not very efficient if you work with a lot of nozzle sizes and filament types. That said, it's a very nice slicer in many ways.

I've attached a sample set for a Mk3 with 0.4mm nozzle, PLA and 0.20mm layer heights. Let me know if you encounter any problems importing these.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Why is the PrusaSlicer Support so bad?

Thanks for that, I will give it a go.