Underextrusion after migration from Slic3r to PrusaSlicer 2.3

When switching from Slic3r to Prusa Slicer 2.3, I also transferred the profiles. For some reason I experience under-extrusion. I do not know which parameter got not transferred or might be affected be the migration. The machine is fine. I used an old g-code file from Slic3r and it printed fine. It must be in the Slicer then.

It is not only under extrusion also the under extruded part is about 1mm taller. Hopefully this gives you pros an indication where to look for the cause of this behavior.

Any ideas?

RE: Underextrusion after migration from Slic3r to PrusaSlicer 2.3

If you zip your project 3mf file and upload it here, folks can take a look at your settings.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Underextrusion after migration from Slic3r to PrusaSlicer 2.3

Hi Fuchst,

sorry for the dum question, but I only have *.stl and *.gcode. Working some time now with 3D printing but seem to have some deicides here and there. Can you help me out here?

Google just said: 3D Manufacturing Format or 3MF

Thanks Pal.

RE: Underextrusion after migration from Slic3r to PrusaSlicer 2.3

3mf is a standard PrusaSlicer uses for its “projects”. They contain the STLs and — most importantly — all your settings.

Simply load the STL into PrusaSlicer, then under File use Save project to create the 3mf file. Unfortunately this forum does not allow uploading 3mf files so you’ll have to Zip it, which you can then upload.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Underextrusion after migration from Slic3r to PrusaSlicer 2.3

Here is the 3mf-File that caused the underexteruded part.

RE: Underextrusion after migration from Slic3r to PrusaSlicer 2.3

A few things stand out as a bit unusual. Firstly the infill perimeter overlap is set to 15%. A normal prusa quality default has that at 25%.

Secondly, are you really only using 2 top and bottom layers ? More is normal and might help your issue.

Those are the first things I'd try.

Other things of note - your start gcode is explicitly setting a temp of 255. For start gcode its normal to use

M109 S[first_layer_temperature] ; wait for extruder temp

as that will set the value defined in your filament settings. So you can change filament types without having to alter your start gcode.

Your first layer is very thick extrusion width, 200% of your 0.35mm layer height is giving you extrusion widths of 0.7mm for the first layer. Is that intentional ?

You have the volumetric flow rate set to 2.5mm/3/s, normally ASA filaments have around 11 for a e3d hotend. Is your hotend really limited in throughput to that extent ?

Does Slic3r store the settings used at the end of the generated gcode like PS does ? If it does and you have the old gcode it might be worth posting it here too and comparing it. While PS will have different settings now, as it was originally based on Slic3r many will still be the same and a cross comparison might be made.

RE: Underextrusion after migration from Slic3r to PrusaSlicer 2.3

Thanks for bringing up these points. I go through them one by one

Firstly the infill perimeter overlap is set to 15%. A normal prusa quality default has that at 25%.

I have to check that. Never looked or adjusted this parameter. Maybe a result of wrong migration.

Are you really only using 2 top and bottom layers ?

Worked very fine for me since over 100 print jobs with the ASA.

Other things of note - your start gcode is explicitly setting a temp of 255. For start gcode its normal to use

M109 S[first_layer_temperature] ; wait for extruder temp

I was aware of this inconvenience and now I now how to make it elegantly. I will change it.

Your first layer is very thick extrusion width, 200% of your 0.35mm layer height is giving you extrusion widths of 0.7mm for the first layer. Is that intentional ?

Thats how I get the ASA to stick.

You have the volumetric flow rate set to 2.5mm/3/s, normally ASA filaments have around 11 for a e3d hotend. Is your hotend really limited in throughput to that extent ?

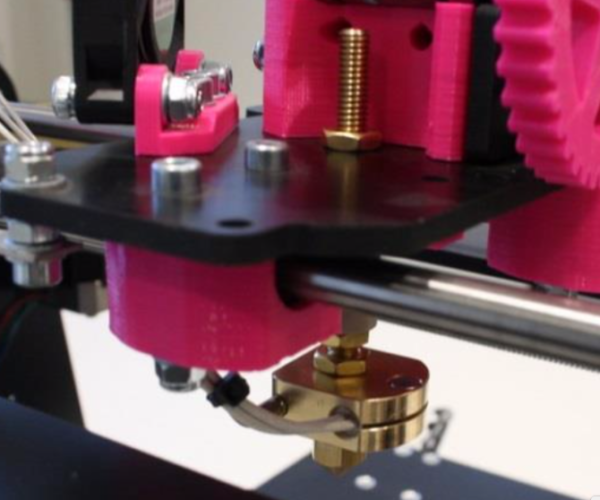

Yes. It is a very old printer Orcabot. Here a picture of the Nozzle

Does Slic3r store the settings used at the end of the generated gcode like PS does ? If it does and you have the old gcode it might be worth posting it here too and comparing it.

Yes it does. You will see that I use some more solid walls in the Slic3r code but besides that the main settings are the same.

SLIC3R File is enclosed.

RE: Underextrusion after migration from Slic3r to PrusaSlicer 2.3

As it turns out the extrusion speed was set to a value that was too high for my printer. With ASA and 255°C it is quite borderline for the machine. Slowing it down brought up the extrusion width and removed the grinding problem. It was just not sufficient energy available to melt all the filament.

Nevertheless I ordered a Prusa MK3 S+ now because it’s just so much quicker and less noisy.