You can do that the same way but it's an extra step and a bit fiddly as you have to allow clearing tolerance. Bonus: a key on its own can be rotated and printed in the strongest orientation.

Cheerio,

RE: Suggestions for improvements - PrusaSlicer

Any chance of giving a sucker a break. A little more detail. I can't see how to aligning the negative and positive components.

RE:

Load object

Right click on object, add negative volume eg., cylinder

Position negative volume where you want the key/keyway and size to taste

Cut

You will probably need to rotate the UPPER part.

You now have two segments and two negative volumes as before.

Select one of the negative volumes, right click and change type to Part.

Resize the part in place (use the Part manipulation pane) to allow tolerance...

and slice.

Cheerio,

RE: Suggestions for improvements - PrusaSlicer

@Diem Sweet! Thanks a million.

RE:

Hi there

thx to bith @swiss_cheese & @Diem for their input, I found a video tutorial on YT on the cut story- I wish to have a tutorial for the fitting holes story as well.

This would be benefitial. I think to get into it. seing it working

RE:

Hi there

I tried to cut with negative modifier . and i see indeed for both part the cut part with the negative part. I used a box and a cylinder.

however it makes both part to be cut and not one is a negative modifier the other a positive modifier or added part...

My bad!!! sorry I had to change the type from negative to part. and this rocks!

I need to see if one can export both partsas stl plate. It worked!!!I need to delete one part and export and voila !!!for part A. undo delete and delete instead the other part and export plate as stl... et voila... part B stl...

RE:

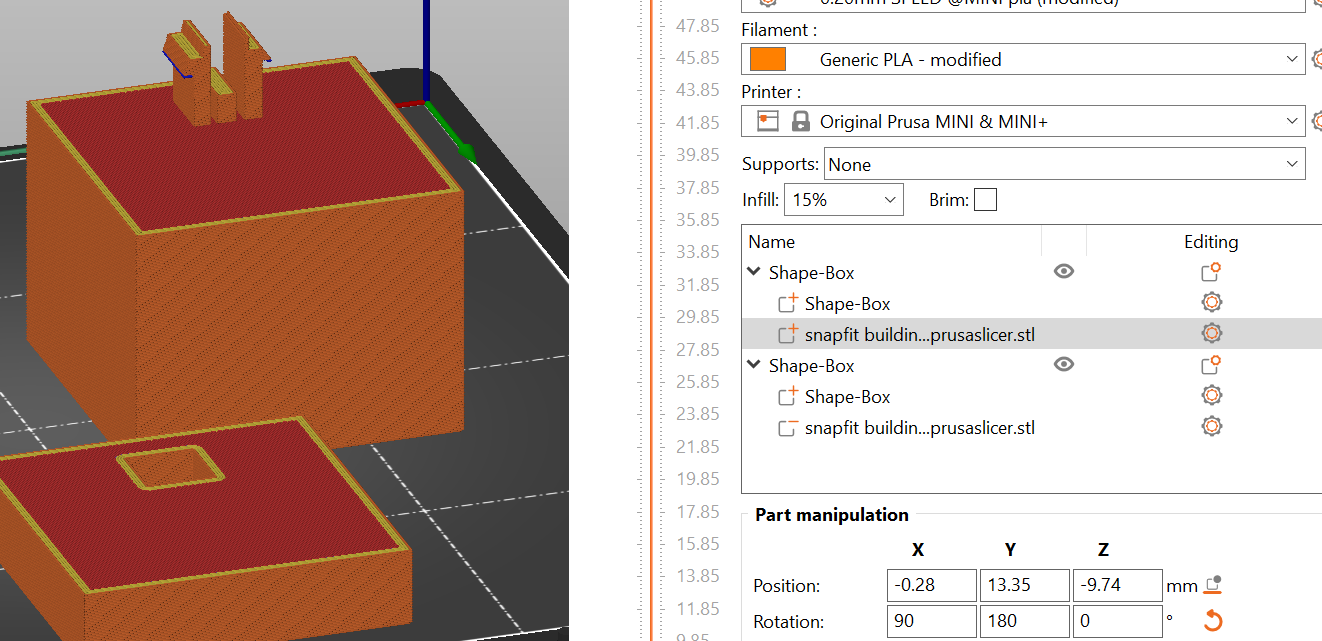

here I tried to add load a snapfitfeature to any block to be cut as a stl attached here. It is a little bit of effort but works . I did nott print a part that way but I believe it will work, a gcode is created succesfully. once you added the snapfit feature to the part you want to. one side of it will become the snapfit male part and need to be a part type object whereas the other will become the female part of the feature, so rotation maybe needed and moving the part along the z axis...sorry big picture

RE: Suggestions for improvements - PrusaSlicer

I added the part by the printables repository. here: Snapfit building block for operation in prusaslicer with two sides by Dr_Froggy_rD | Download free STL model | Printables.com

Why? You haven't even printed it, let alone tested it properly.

Please don't post untried parts, they only confuse newbies when they cannot make them work.

Cheerio,

RE: Suggestions for improvements - PrusaSlicer

Hi there, I indeed not tried it yet in that configuration with PSE- but this design do work. I did already snapfit design succesfully. I just took the exact snapfit part working for me on another design and cut it away to make it a lone part. but it still needed to be also the female part to work as intended. Iam now printing something different until tomorrow morning I will try tomorrow to print a small part as an example. a mold. the slicing looks promissing sofar.

Please test print *before* posting, don't guess.

Cheerio,

RE:

here a succesful example print using my guess design...As said I was not guessing I did already use it in another design (and printed there) so I know it works. and the gcode view was clear enough. however I needed to adapt the size of the pad part ... it needed some scaling to get it right. this is always a problem achieving the right dimension to achieve the snapfit. I think I can work out several snapfit design to be added to your shapes repository for the same purpose. on the left to part male and female on the right the connected parts

however I needed to adapt the size of the pad part ... it needed some scaling to get it right. this is always a problem achieving the right dimension to achieve the snapfit.

QED

Cheerio,

RE: Suggestions for improvements - PrusaSlicer

because of the xy compensation and tolerances I have to set the scale of the cut tool to 1.15 times the size of the original designed part although it does work it is quite tedious and I am sure one can found better way of doing that. again I knowPSE is not a cad software but it shows very interesting features that one can use at his advantage this was all about it. So can we make a snapfit feature to integrate it to a part in PSE from what I did yes it is possible. It is tedious but you can get it working. th

RE: Suggestions for improvements - PrusaSlicer

Hi there,

when I saw the last video aboutOriginal Prusa XL update on development and shipping schedule

dealing with a stuning helmert of iron ma with a lighting infill like support...called organic support there. I must applause it is almost what I proposed earlier!!!

cheers

frog frog!

RE: Suggestions for improvements - PrusaSlicer

It would be really cool if I could simulate a 3d print based off of the generated gcode. It basically already does this, but it would be cool if it could be ran in real time.

RE: Suggestions for improvements - PrusaSlicer

Hi Prusamates. I come back with a feature request on printables.

I saw that the automatic cut tool do exactky what I proposed on an earlier post . I am glad to see that. however I would ad a point>>> stop doing round stuff use hexa based geometries instead. or give people the possibility to use their own snap fit form.

I came to this because we all know here the issue with round moves... so go for hexa straigth line it workd best.!

I am working o a way to have multiple filament print on a single object.

the problem i: I want to print each filament according to their own filament and print settings in prusa

please give the option when choosing change filament to use the right filament setting for each one!

because Now I am not sure this is correct...

I did that manually and this is far from perfect. I am asking myself: what if I do

the last one on the go. with little help.

The Surprising Practical Uses of Color Change in PrusaSlicer - YouTube:

Frog Frog.

RE:

I did not reply to this forum thread since a while. I looked at what prusa did and implemented the cut with a snapfit possibility instead of the nipples or small snipplet. please change the bow tie junction (the dovetail cut) to a bowtie hexagonal version of it: the printability will be further improved. So I am very glad to see that what we suggested here were followed by the dev at some point... lthough we may have a co-evolution in theway one may think the future of 3d printer...

a further point:the change filament point>> I need to add a custom filament gcode: on the filament M104 S245 M600. I try to print tpu on pla. I know not the best way... I have found a way around without structural interdigitating the two materials... No I do not have a MMU or a multimaterial set up. I oad the filament manually....

another way could be to add in the gcode filament filament change in the height modifier part in order to force the use of a filament change and using a custom filament profile... Or you think that will kill the MMU selling.. I do not think so.

I am williing to buy one but sadly the mini is a bowden feedeed extruder.... therefore rthe first thing would be to get the possibility to get a simple extruder motor to mount on it like the one made for the easythreed ridiculous printer ( yes I own one as well)...which is at the moment is a 80 euros dust trap ... as some quality of the housing make it unusable...the motors are really lightweighted... the problem I cannot mount it and connect them directly above the extruder hot end... sorry for the disgressing side slip.

Best Regards,

Frog Frog

RE: Suggestions for improvements - PrusaSlicer

Hi Prusamates,

I had a further idea. Do you think It will be possible to get control of the prusa mini using a esp32 usb drive? or to control the printer by wifi usb thing.

will be awesome.. I think....Maybe I am wrong but. I thought wifi on the mini has not been implemented yet...

K.Regards

Frog frog

Keyboard Shortcut

As a huge fan of shortcuts I highly recommend adding a keyboard shortcut to Import STL(imperial units). Please and thank you!