PrusaSlicer is cutting my object when I slice it

Hi,

I'm opening an STL file exported from Fusion 360.

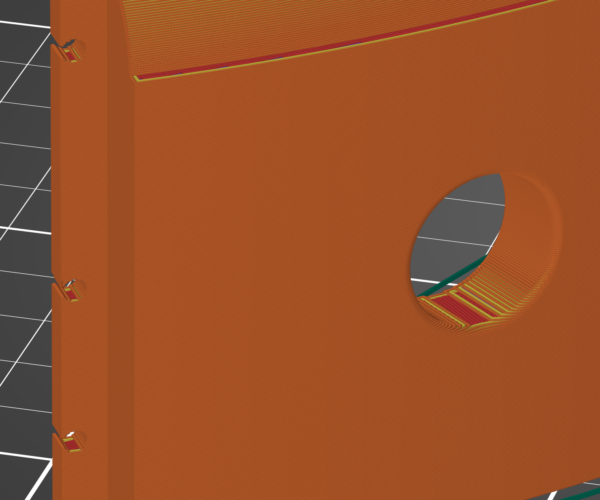

When opened, the STL looks like the green one. When I slice, it looks like the orange one (so it has some missing parts near the small holes).

I tried to keep all the default settings and tried exporting again with Fusion but nothing is changing.

Thank you for your attention,

Andrea

Best Answer by JoanTabb:

Hi Andrea,

these portions are probably narrower than the nozzle can print...

the nozzle is say 0.4mm diameter and Prusa Slicer increases the extrusion width to cause the filament strands to bond together,

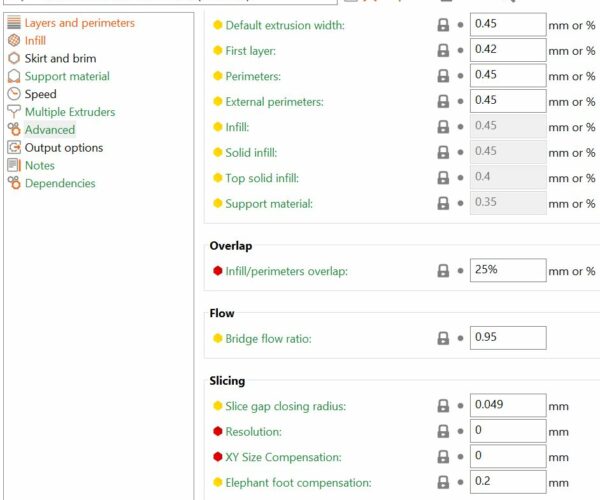

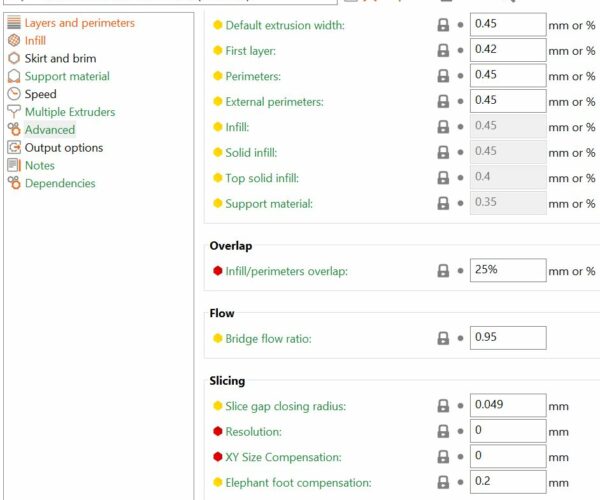

As you can see above your external perimeters will ne extruded at default 0.45mm width .

if your missing part is smaller than this extrusion width, the part will be ignored

You could try rotating your model 90 degrees so that the narrow edge with the missing parts is either up, or down so that your layer lines go along the edge rather than across the edge

you could try slicing the model with a setup for a 2.5mm nozzle and see if that shows the part for you,

or

you could re model the part in fusion360 such that the holes are a little further away from the edge of the print making

the area you are interested in, marginally thicker...

Or you could consider using a smaller hole

Or

you could try setting your external perimeter extrusion width a little thinner, say 0.42mm

Or

you could try thin wall detection

Or

you could try setting XY Size Compensation to say o.1 or 0.2mm (See picture above)

this setting marginally changes the dimensions of your model, so be careful if the parts need to fit closely with other parts.

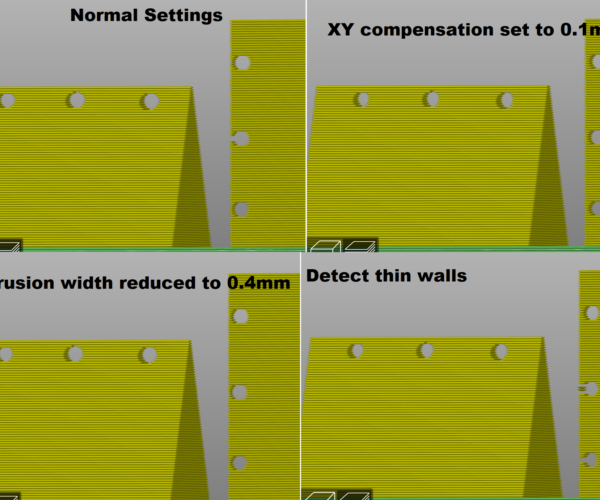

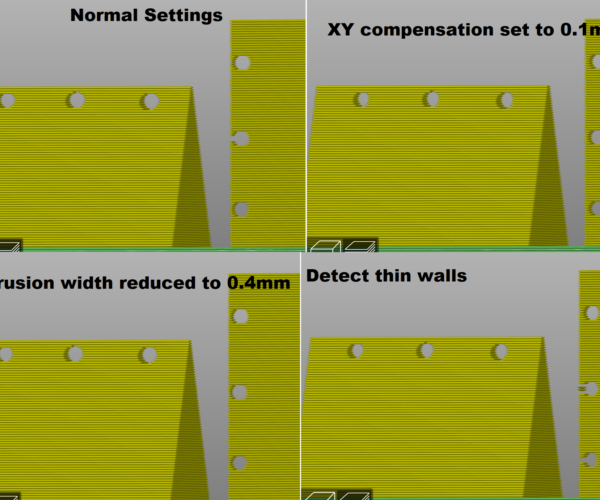

in the image above,

there are three holes near the edge of a triangle edge... in the normal settings image, the middle hole replicates your situation, the bottom hole is marginally smaller diameter, which allows the edge of the hole to form, the upper hole is original size but marginally further from the edge which allows the edge of the hole to form. the wedge with the holes along the top, allows all holes to form because the layer height (0.2mm) is thinner than the normal extrusion width!

In the extrusion width reduced image, I have reduced the external perimeter, extrusion width from o.45 to 0.4mm this is not a particularly good option, because the layer bond to the rest of the model may be compromised, you would need to try this....

you would get a better solution by using a smaller nozzle, but that's a load of messing about

In the XY Compensation image, I have increased the XY size Compensation to 0.1mm, which allows the edge of the hole to form...

and the last image... detect thin walls gives a really odd result... it finds the edge of the hole, but creates a gap above and below where there previously wasn't a gap....

see which you want to use with your model... your model will have different geometry, so the results may be slightly different...

regards Joan

RE: PrusaSlicer is cutting my object when I slice it

Hi Andrea,

these portions are probably narrower than the nozzle can print...

the nozzle is say 0.4mm diameter and Prusa Slicer increases the extrusion width to cause the filament strands to bond together,

As you can see above your external perimeters will ne extruded at default 0.45mm width .

if your missing part is smaller than this extrusion width, the part will be ignored

You could try rotating your model 90 degrees so that the narrow edge with the missing parts is either up, or down so that your layer lines go along the edge rather than across the edge

you could try slicing the model with a setup for a 2.5mm nozzle and see if that shows the part for you,

or

you could re model the part in fusion360 such that the holes are a little further away from the edge of the print making

the area you are interested in, marginally thicker...

Or you could consider using a smaller hole

Or

you could try setting your external perimeter extrusion width a little thinner, say 0.42mm

Or

you could try thin wall detection

Or

you could try setting XY Size Compensation to say o.1 or 0.2mm (See picture above)

this setting marginally changes the dimensions of your model, so be careful if the parts need to fit closely with other parts.

in the image above,

there are three holes near the edge of a triangle edge... in the normal settings image, the middle hole replicates your situation, the bottom hole is marginally smaller diameter, which allows the edge of the hole to form, the upper hole is original size but marginally further from the edge which allows the edge of the hole to form. the wedge with the holes along the top, allows all holes to form because the layer height (0.2mm) is thinner than the normal extrusion width!

In the extrusion width reduced image, I have reduced the external perimeter, extrusion width from o.45 to 0.4mm this is not a particularly good option, because the layer bond to the rest of the model may be compromised, you would need to try this....

you would get a better solution by using a smaller nozzle, but that's a load of messing about

In the XY Compensation image, I have increased the XY size Compensation to 0.1mm, which allows the edge of the hole to form...

and the last image... detect thin walls gives a really odd result... it finds the edge of the hole, but creates a gap above and below where there previously wasn't a gap....

see which you want to use with your model... your model will have different geometry, so the results may be slightly different...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: PrusaSlicer is cutting my object when I slice it

@joantabb

Thank you very much for your complete answer 👍 🙂 !

It seems that adding an extra box (the green one in the image attached) in that side (to make the perimeter width larger) makes the object slicing as I want 😀 .

Do you know if in PrusaSlicer I can put the bottom base of the green box in a higher position than z=0.0 mm? Because I'd like to put the two shapes at the same height but if I move the box upper it return to z=0.

Thank you again

RE: PrusaSlicer is cutting my object when I slice it

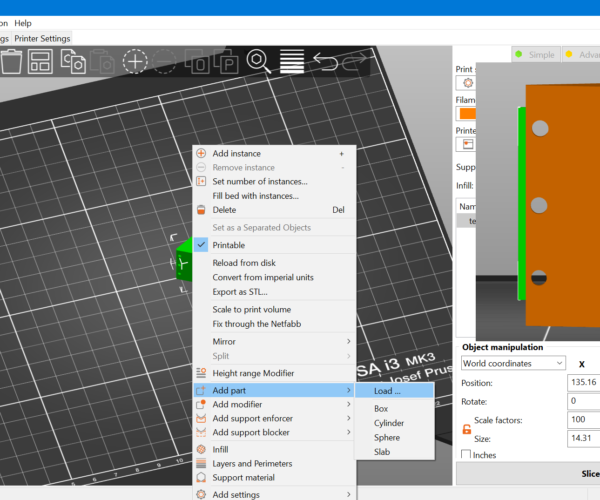

Instead of adding 'the green box' which btw is called an object to the plater you need to add it to your existing object.

All Objects in PS have to touch the build plate. As you have seen it wont let you place an Object in mid air. Also if you overlap 2 Objects it will end badly, as each Object is sliced individually, so it will try and put 2x the plastic into 1x the area.

Instead of right clicking the bed, right click your existing Object. When you right click an Object and add part you still have 1 Object but it now has multiple Parts. You can see the difference in the tree view on the right. Parts are listed under the Object name. The rules for Parts are different to Objects.

As long as SOME part of the Object touches the bed other Parts can be placed where ever you want, even in mid air. Also when sliced any Parts that overlap are sliced as one, that means it combines their perimeters and infill.

RE: PrusaSlicer is cutting my object when I slice it

@barca95

I expect you simply added the box onto the build plate...

If you right click on the original part, in the 3d viewer window of Prusa Slicer, and choose Add Part (Load)

this allows you to add a part from file, and allows you to manipulate the relative positions as required,

see the attached image, the left side shows the Meu option, the insert on the right shows a green box inserted in mid air at the nose of the triangular piece

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK