Printing multiple parts nested? Bed Jigs?

If this has been discussed before please point me to it.

I am wandering if it is possible to print two components one at a time in this scenario.

Say I am making a phone/tablet case... back plate and sides. I want to print it "back up" and starting on the sides. Yes I know I could print it back down but I want the bed finish to be on the side edges (face) and not the back of the case.

So the middle area would need a lot of support material in the phone or tablet pocket against the bed. The entire back area would be "bridging"

Has anyone printed a "jig", in this case a phone or tablet body as a jig onto the bed, then printed a solubale filament layer onto it prior to doing a filament swap with the actual part (case) on top and around that?

Working with a single extruder...

I imagine I could design the jig as another part to print first with the second primary part centered around that on top...wandering how the slicer could handle this? If it already has tools that could help with this?

Has this been done before....prior to me reinventing the wheel?

I assume I could do two prints with the jig part down first. Then I could slice the actual part centered on top of that and have it avoid crossing paths internally so the nozzle does not run into the jig (first part)...

Say I am printing a box. Opening on bottom (bed) and I want to print the inside cube as a support on the bed first in a different filament. Offering a "Jig" on the bed to print the box around...

I am trying to prevent having to pull a 5-10 inch, flat piece of support material out of the inside of the phone/tablet case every single time as I would be printing 50-100 of these repeatably. I want to essentially build a bed template of the phone or tablet to print onto, to provide a smooth shaped surface to repeatably print onto with minimum post production.

We currently machine these and looking for ways to introduce hybrid versions of 3D printing into our manufacturing...if that becomes possible.

As we machine "jigs" for our CNC...I'm interested to learn if we could "slice" a 3D print around a bed that has a "jig" printed onto it for repeatable support.

Appreciate any thought on this and I can supply more information/images to help paint the picture as needed to get this conversation going.

If anyone out there is tracking on what I am saying and is smarter on this slicer than I am, I'd like to hear your thoughts and ideas.

Damian

Founder/Owner of LEADNAV Systems

www.leadnavsystems.com

RE: Printing multiple parts nested? Bed Jigs?

Note: Also I understand the nozzle clearance would have to be taken into account...but in this case we are dealing with a case that would be fairly flat and housing a tablet or phone that would require a jig narrow enough to not interfere with the nozzle clearance.

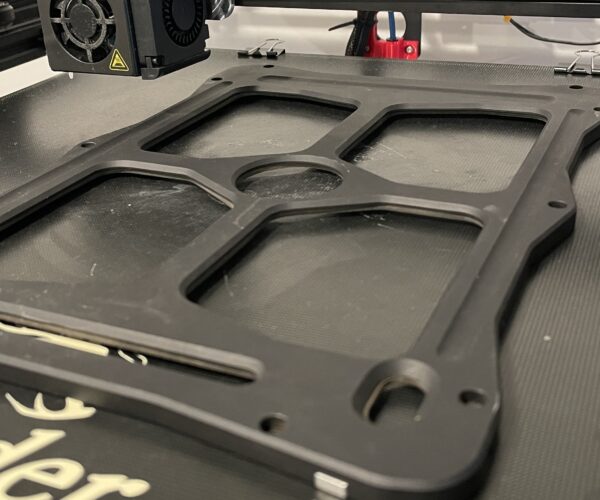

Here is a sample of what I am trying to do. I also own a Prusa...so do not judge me for laying this out on an Ender..but this is a machined out case back and laying on the bed how I would like to print it. I'd like to print the support in the middle and looking for possible options other than needing to pull out that much support material when printing high temp Nylons.

RE: Printing multiple parts nested? Bed Jigs?

It's fairly straightforward to stack parts as long as their footprints permit and using one to support the bridge of another is just a matter of careful spacing. There is a whole class of print-in-place mechanisms that rely on the technique; they are in effect seperate parts even if they are meshing.

That said, the sample part you pictured looks like something intended for injection moulding, not printing. Are you able to rework the design to take advantge of the medium? Or even slice it in two horizontally and join the parts post printing?

Cheerio,