RE: Pause, vibrate, pause, print? Help! 😘

How hard is it to move the bed back and forth? The gcode to do this function is NOT complex. If you have done any mechanical design, you'd also know this is the only way to "vibrate" the part.

Your expert friend should be able to write a "vibrate" routine in that minute you believe the work will take others. So honestly, I'm not sure why you are even asking for help.

G91:G1 Y2:G1 Y-2 F3000:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G90

Add G1 Y2:G1 Y-2: as need for the length of time you want it to buzz... and modify F3000 to raise or lower the speed.

RE: Pause, vibrate, pause, print? Help! 😘

How hard is it to move the bed back and forth? The gcode to do this function is NOT complex. If you have done any mechanical design, you'd also know this is the only way to "vibrate" the part.

Your expert friend should be able to write a "vibrate" routine in that minute you believe the work will take others. So honestly, I'm not sure why you are even asking for help.

G91:G1 Y2:G1 Y-2 F3000:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G1 Y2:G1 Y-2:G90Add G1 Y2:G1 Y-2: as need for the length of time you want it to buzz... and modify F3000 to raise or lower the speed.

I didn't call anyone an expert... We're hobbyists. This is for fun, remember that stuff? Why do people feel the need to act like complete heels here. Am I in the wrong forum or what? Good grief.

RE: Pause, vibrate, pause, print? Help! 😘

@kenour As noted, there is no looping or conditional branching in gcode. You could write an Octoprint plugin do send "forward and back" motion commands as long as desired. However, that's a key consideration: your "vibration" is going to consist exclusively of Y axis movement. That might not shake out bubbles in pockets off to the sides. The mechanics of an i3-style printer can only move the bed in Y.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Pause, vibrate, pause, print? Help! 😘

@kenour As noted, there is no looping or conditional branching in gcode. You could write an Octoprint plugin do send "forward and back" motion commands as long as desired. However, that's a key consideration: your "vibration" is going to consist exclusively of Y axis movement. That might not shake out bubbles in pockets off to the sides. The mechanics of an i3-style printer can only move the bed in Y.

Thanks so much for that, that's all I was after. Yeah aware of the limitation of movement (wasn't aware of the gcode loop limitation, but makes sense), all good. Just wanted to play around, see if it could work, or potentially cover my study in uncured resin 😂 I mean I really don't need the loop, I just wanted to fine tune the time per volume. Once that's figured out I would just adjust the time based on the volume. Resin and mixers arrived yesterday, keen to give something a crack. Might just do a rectangle and see how strong it makes it to start! I'll put a link up once done. It will be behind a paywall though. Please like and subscribe to support future content, remember to ring that bell, and if you would consider becoming a patron... 😂😂😂 Get a job! 😘 (Not you Bobstro 👍)

RE: Pause, vibrate, pause, print? Help! 😘

Needless to say: You should experiment a bit before trying this live. Having a leaky print might be... problematic.

I think it was CNC Kitchen that used a syringe (or turkey baster?) to inject epoxy into prints with low infill percentage using an open pattern. Might be simpler and safer. Plus you can do bigger batches than would fit on the bed. You could put filled parts on a vibrating surface ... Without risking a pricey Prusa.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Pause, vibrate, pause, print? Help! 😘

@bobstro

Fortune favours the bold! 😂

I was going to print it with a thick skirt to hopefully catch any boo boos. I'll be going live with a thermal camera because I want to set how the resin interacts with the heated bed. Should speed up the whole process. Either way will share results! 🤙

RE: Pause, vibrate, pause, print? Help! 😘

I see melted plastic in your future. Good luck.

RE: Pause, vibrate, pause, print? Help! 😘

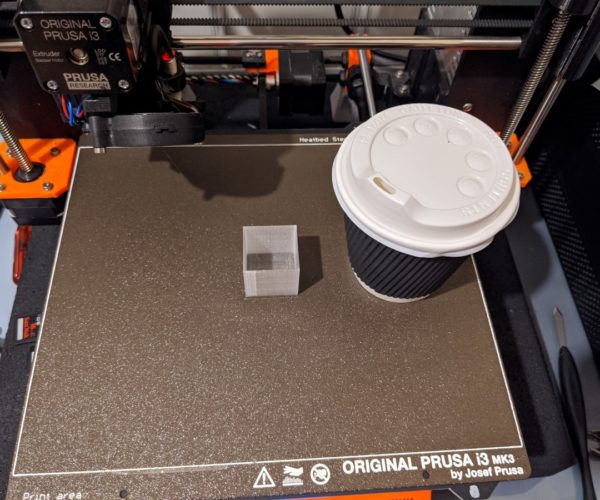

So yeah, I totally got bored and just did it.

I'm using WS 105 and the fast hardener as pictured. Each pump is approx 0.8fl oz, so I converted that to NON IDIOT units and got 23.6588ml, which as we know converts directly to cubic centimeters. I took the cube root and got 2.8438cm³, I then rounded down to allow for wastage (not enough apparently) and made a hollow cube in F360.

Printed the cube in clear PETG, mixed the resin, put a M601 in because I wanted the bed still hot to hold the piece and speed up the reaction.

And away we go! Exciting stuff.

With wastage it was just shy of the top of the container, so I'll take 10% off next time. But only for the first pump as wastage shouldn't scale.

The reaction was... energetic to say the least. But worked exactly as I expected it to. The cube did warp slightly in some areas with bubbles forming on the surface (I started with 1mm wall thickness because why not). Thicker walls should reduce this issue. I sprayed the bed (which was at 90°) with IPA to rapid cool it to remove the part. As you can see, the heat generated by the reaction is obviously higher than the temp of the bed, I didn't have the FLIR on it, but it's pretty obvious... things got hot.

I popped it off the bed, put it on some tinfoil to cure, it actually cured quicker than I expected, I'm taking 10 minutes. I knew the heat of the bed would speed up the reaction (obviously, it's how chemical reactions work...), but this was a fantastic result. So next I'll shrink the size (to account for the extra wastage), print with thicker walls, fill it to the brim, wait for it to cure, or at least start to go tacky, then try to print straight on top of the resin (I think the tacky stage would be the best to try and print on it as when it sets it's pretty hard and slippery).

Anyway, didn't need vibration for a cube as the temp of the bed reduced the resins viscosity, may need it for more complex models. Good result, outstanding mechanical hardness, happy days.

Cheers.

The full results can be found on my patreon site... 😘👍

RE: Pause, vibrate, pause, print? Help! 😘

What does the print bed look like now?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Pause, vibrate, pause, print? Help! 😘

@bobstro

Exactly the same as it did before 👍

RE: Pause, vibrate, pause, print? Help! 😘

So I tried a new test, I printed a 30mm cube, with 5 perimeters, 25 bottom layers, 10 top layers, and 10% gyroid infil.

I thought I would try to stabalise the print with gyroid, plus the geometry means there are no cells, so I can pour resin in the top and it will get into all the nooks and crannies. I might cut it open with the drop saw in the morning to check penetration, bit loud to do it at the moment though.

Because none of you awesome dudes wanted to help a brother out, I had to think "outside the box" to vibrate the bubbles out. My solution worked a treat! So yeah, there you go, has another use... outside the box. 😍

I smoothed it over a couple of times with a tongue depressor until it started to rapid cure (the heat from the bed really speeds up the process, I had some left over in the cup next to it as I wanted to measure the differential curing time, it still hasn't cured).

I then resumed the print only to notice an interesting development, it appears the heat of the curing process had shrunk the print on the bed.

Measuring the shrinkage of the base (giggity), it gave me about a 0.67% uniform dimensional reduction.

Under the lip at the top it was 1.67%.

The top however was dimensionally accurate.

So because this is so much fun, I'm going to go full scale and see what happens 🙂

For anyone who is super bored and wants to watch the print resume and it printing directly on resin, be my guest: https://photos.app.goo.gl/9uMXBx7EsHMFmvpd7

Cheers all, thanks to everyone who contributed to this little experiment.

RE: Pause, vibrate, pause, print? Help! 😘

These are the images that are supposed to be where the duplicates are. Couldn't edit, dunno what's going on. (Edit: As in I know what's going on with the edit timer, just not what's going on with the images... anyway.)

RE: Pause, vibrate, pause, print? Help! 😘

My other thought is that if the heat from the bed it causing too much on an issue, I would print the model with a hole at the top, let it cool, fill it, then pring a plug for the hole that I would embed in the resin afterwards. Hopefully the reaction will be a bit slower and less destructive.

RE: Pause, vibrate, pause, print? Help! 😘

My other thought is that if the heat from the bed it causing too much on an issue, I would print the model with a hole at the top, let it cool, fill it, then pring a plug for the hole that I would embed in the resin afterwards. Hopefully the reaction will be a bit slower and less destructive.

RE: Pause, vibrate, pause, print? Help! 😘

You are a rather odd person Kenour - I posted a vibrate routine. But you ignored it and called us names.

You are most welcome.

RE: Pause, vibrate, pause, print? Help! 😘

You are a rather odd person Kenour - I posted a vibrate routine. But you ignored it and called us names.

You are most welcome.

Thanks for the unwanted assessment. I ignored everything after 'how hard is it' because I have a blind spot for anyone with the classic unearned IT arrogance... If I handed you a buzzer and asked you to straighten a wall then screamed 'how hard is it', I would look like a complete heel, as it's something you may not have an interest in, and have absolutely no desire to learn. But I wouldn't do that, because I'm not a wanker 😘

What's this 'us' business, aren't I a part of the 'us'. I mean, aren't we all in this together, I own a Prusa, I contribute from my distinct knowledge set where appropriate, what's with the 'you and us' distinction. Everyone was a beginner once.

You have a delightful day 🤗

RE: Pause, vibrate, pause, print? Help! 😘

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Pause, vibrate, pause, print? Help! 😘

Why do 'you people' feel it necessary to phrase things like this? Always trying to one up people to appear cool to a bunch of people that don't matter. Deary me...

I'm not making art, I'm using my tool, to make other tools and guides. As a tool, I see the PEI sheet as a consumable, and couldn't give two shits if it gets damaged, because, A) it has another side, and, B) they made more than one. I'm not precious about my tools, they're for work...

What I'm trying to achieve here is (because I'm somewhat of a 'process and efficiency engineer', although that was a lifetime ago) is constantly examine what I'm doing, and streamline processes if at all possible. I'm also focussed on sustainability and recycling, and have been before it was cool.

If I'm printing large functional pieces that need specific external dimensions, but also need to be rigid, if I can cut time down and increase the strength of prints by introducing an epoxy, why not try it out.

I've often looked at my waste bucket, and thought I wish there was a way of reusing that PETG, without reprocessing into filament (and the energy required for that). I was thinking if I could turn it into an aggregate (probably with a blender, because, why not), I could add it as a filler to the resin and recycle on site with limited energy inputs. If I can make parts from 50%+ plus recycled PETG and use resin as a binder, why wouldn't I give it a go, saves it going to landfill.

Anyway, from the full scale experiment I just did, the shrinkage is about the same, and when the next layer was printed, it was misaligned due to this shrinkage. So, might put this experiment to bed for now, the heat created by the curing process is too harsh on PETG.

I have some nylon carbon fibre I might give a crack later. Just hoping the Prusa XL can print the nasty stuff! Give me that 400C hot end.

Anyway, like and subscribe, and remember to ring that bell, and all that other nonsense self promotional garbage 😘

RE: Pause, vibrate, pause, print? Help! 😘

Why do 'you people' feel it necessary to phrase things like this?

OK Don Cherry... I did say "sounds to me like". You're using an expensive piece of equipment to do something it's not particularly well suited to. I am curious why you find it demeaning when someone says as much. "It's not the best tool for the job" is not an insult, it's a response to your query. A normal part of a 2 way exchange. Or is this meant to be a one-way presentation?

Always trying to one up people to appear cool to a bunch of people that don't matter. Deary me...

I'm responding to your posts in a civil manner asking for more elaboration. I'm sorry you find that bothersome, but you have to admit, what you're doing isn't exactly the normal 3D printing approach.

I'm not making art, I'm using my tool, to make other tools and guides.

Is "art" somehow offensive? You're doing your thing your way. Your toys, your rules. I've made some suggestions and comments about the process.

As a tool, I see the PEI sheet as a consumable, and couldn't give two shits if it gets damaged, because, A) it has another side, and, B) they made more than one. I'm not precious about my tools, they're for work...

OK. I was attempting to discuss the process with you, but you seem to want to martyr yourself over it. Have fun.

What I'm trying to achieve here is (because I'm somewhat of a 'process and efficiency engineer', although that was a lifetime ago) is constantly examine what I'm doing, and streamline processes if at all possible. I'm also focussed on sustainability and recycling, and have been before it was cool.

I thought that was interesting, but you seem offended.

If I'm printing large functional pieces that need specific external dimensions, but also need to be rigid, if I can cut time down and increase the strength of prints by introducing an epoxy, why not try it out.

Epoxy fill is definitely an interesting approach. I was thinking a discussion about alternative means of achieving the same end -- not everyone here has as much money as you to throw (un-recyclable) PEI sheets away after all -- might be interesting. Most forums are intended for discussion, not diatribe.

I've often looked at my waste bucket, and thought I wish there was a way of reusing that PETG, without reprocessing into filament (and the energy required for that). I was thinking if I could turn it into an aggregate (probably with a blender, because, why not), I could add it as a filler to the resin and recycle on site with limited energy inputs. If I can make parts from 50%+ plus recycled PETG and use resin as a binder, why wouldn't I give it a go, saves it going to landfill.

That's an interesting approach. It might have been interesting to have a reasoned discussion about the goals and alternatives for cost-effectively achieving those ends. Perhaps someone else will care to have a discussion on the topic. I'll keep looking.

Anyway, from the full scale experiment I just did, the shrinkage is about the same, and when the next layer was printed, it was misaligned due to this shrinkage. So, might put this experiment to bed for now, the heat created by the curing process is too harsh on PETG.

Shame. Interesting attempt.

I have some nylon carbon fibre I might give a crack later. Just hoping the Prusa XL can print the nasty stuff! Give me that 400C hot end.

Anyway, like and subscribe, and remember to ring that bell, and all that other nonsense self promotional garbage 😘

Ah yes, YouTube might be the best way to present this. Fewer annoying responses that way. Have fun.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Pause, vibrate, pause, print? Help! 😘

I don't do feelings, or offence. I just get bored dealing with all the 'tude people seem entitled to give when discussing anything 'computery'. You realise normal people don't talk like this? The poultry forums, woodworking, brewing, winemaking, beekeeping, aquaponics, gardening, and every other forum I'm involved in with my other hobbies don't have the giant chip on their shoulders people on technical forums seem to have. Probably why I got out of IT. So much underserved arrogance 🤷♂️

Anyway, will keep plodding along, have a delightful evening.