Okay, any examples of ironing IMPROVING prints?

I've tried the new ironing feature a few times (less than a handful) and have been consistently unimpressed. I'm curious if folks have any examples of it improving their prints and for what kind of models I should expect an improvement.

Here's an example from when I tried it again this afternoon. I thought I had the perfect model, a print-in-place foldable phone/tablet stand that my wife includes as a small gift in her holiday letters to friends and family. Plenty of flat surfaces I assumed would make it the ideal target for ironing.

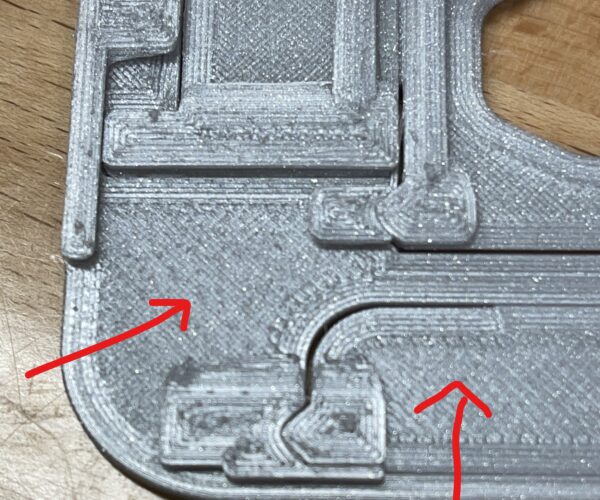

Here's a picture of the model printed without ironing. 0.1 mm layer height, 10% infill, Prusament Galaxy Silver PLA with essentially the stock profile. A nice, consistent, smooth, monotonic surface. (Don't know why it looks blue in the picture, must be the lighting).

Here's two pictures from the ironed version. Best I could do with my iPhone, in reality the "defects" are actually more pronounced. Same settings, just ironing turned on.

In the first, you see that in the middle of these regions there's what looks like smooth areas, which are actually the opposite, i.e., very rough, "grainy" to the touch, whereas the edges still show the standard line patterns.

In the second picture, the ironing created a pronounced pattern of long stripes, plus the left arrow points to other areas of grainy surface structure. (I actually just noticed some stringing here as well, not sure why ironing should cause it but I didn't see it without ironing).

I guess there's ways to tweak it but I would have thought that the default parameters would yield something a bit more impressive. Such as monotonic infill, for example, which works great and makes a huge difference on any flat surface with holes.

As I said at the beginning, this is not meant to bitch but to better understand when and how I should expect ironing to make a difference in quality that justifies the extra time.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Okay, any examples of ironing IMPROVING prints?

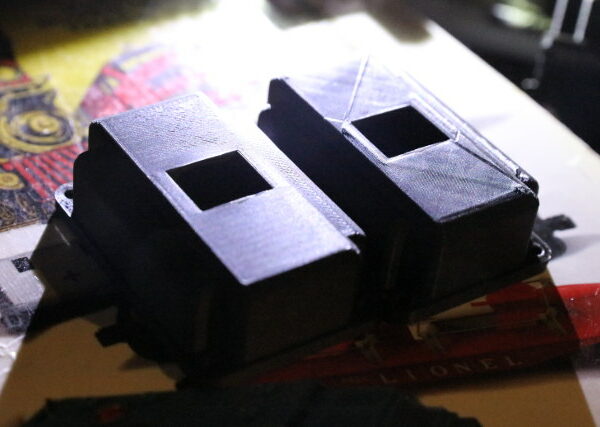

I posted this in another section. Although the first attempt is not perfect, it shows the potential.

The top photo below shows the body for a model railroad control switch sliced with the Beta slicer with ironing on the left. On the right, is the same sliced with Cura using their ironing function, which actually made things worse.

The bottom photo, rightmost item, shows the 'brush strokes' which were smoothed by the ironing. The center one has these too, but the light for the photo does not make it obvious. The leftmost item in the bottom photo is the original switch that I have cloned.

I'm sure that if I played with the settings and/or the Z calibration a bit, I could get the top of the item to be more consistently smooth.

Bottom line, I do think the PS's version of ironing has some great potential.

RE: Okay, any examples of ironing IMPROVING prints?

I've had very nice surfaces with ironing. If you're over-extruding even slightly, the results may be rough. Also be sure to use Monotonic infill. That infill pattern alone gives nice flat top surfaces.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Okay, any examples of ironing IMPROVING prints?

@bobstro

Yes, that's been my experience too. Monotonic infill does such a great job that I for one don't really see the need for ironing.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Okay, any examples of ironing IMPROVING prints?

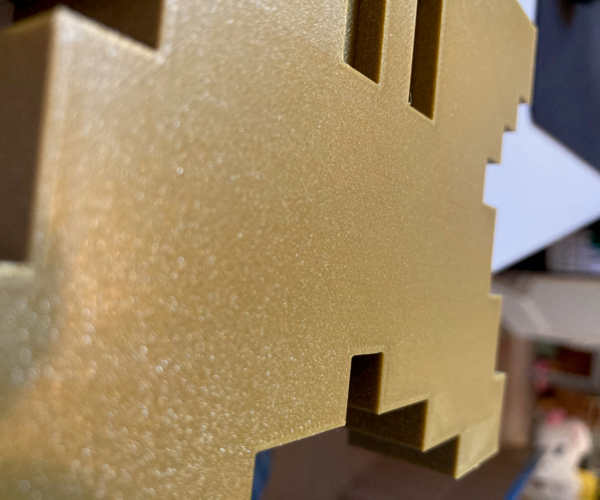

I like the feature but it needs a bit of tweaking on my Prusa Mini to get the expected result. Most of the prints I try with the default settings start nice but after a couple of strokes it stops making a smooth surface. Most of the time 20% flow rate gives me the most static performance on most of the large surface prints. Some examples below.

1. No ironing: 0.15 Quality profile for Prusa Mini using Monotonic, Fillamentum Gold Happens using Fillamentum profile in slicer.

2. Ironing with default settings (15% flow rate, 0.1 spacing): 0.15 Quality profile for Prusa Mini using Monotonic, Fillamentum Gold Happens using Fillamentum profile in slicer.

Started nicely

But somewhere along the road this happened

3. Ironing with additional 5% flow rate - 20% flow rate, 0.1 spacing: 0.15 Quality profile for Prusa Mini using Monotonic, Fillamentum Gold Happens using Fillamentum profile in slicer.

Much better result. A flat surface but clearly visible "blocks" of lines and a rough surface on some of the parts after an edge. Maybe a bit of offset from the edge might help here?

Another test on a smaller surface with some more gaps/edges:

4. Ironing with - 20% flow rate, 0.1 spacing: 0.15 Quality profile for Prusa Mini using Monotonic, General (Platicz) White PLA using General PLA profile in slicer.

Started nicely but ended up messy

4. Ironing with - 20% flow rate, 0.2mm spacing: 0.15 Quality profile for Prusa Mini using Monotonic, General (Platicz) White PLA using General PLA profile in slicer.

RE: Okay, any examples of ironing IMPROVING prints?

I had a play with it in Cura, the trick seemed to be to get the correct flow.