Model designed with walls of 1 extrusion width, are broken when sliced

In my model, I included a wall with a width of 0.45mm (1 extrusion width, as defined in PrusaSlicer). The CAD model looks correct, the STL model looks good, and the STL model looks correct when imported into PrusaSlicer, but when sliced in PrusaSlicer, the wall is broken. Please see the images.

What is the root cause of the broken walls?

How do I produce a sliced object that keeps the 0.45mm wall intact?

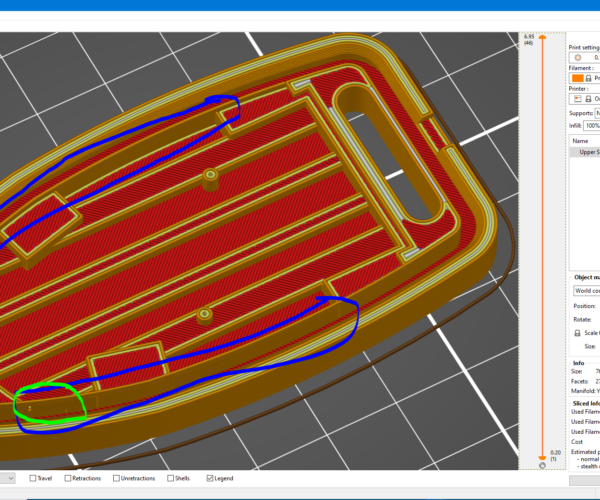

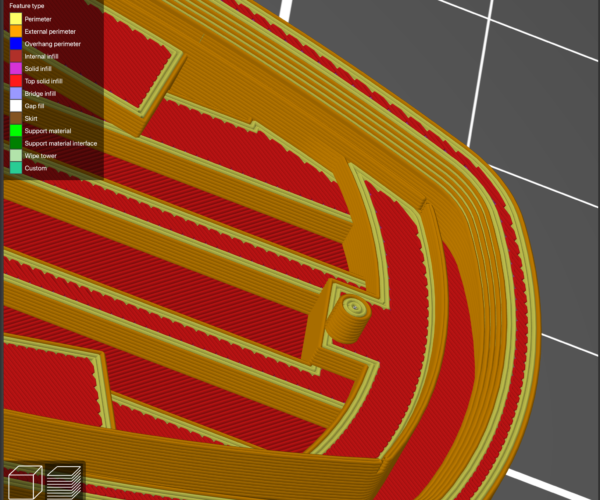

0.45mm wall is intact when imported into PrusaSlicer:

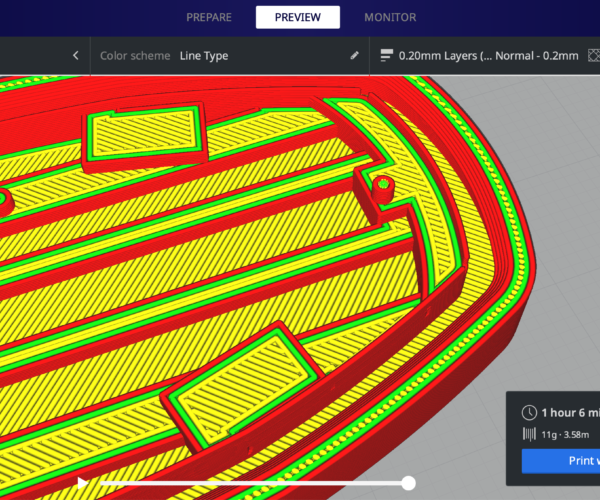

0.45mm Wall is broken after slicing in PrusaSlicer:

Prusa i3 MK4S Kit in Lack Enclosure

RE: Model designed with walls of 1 extrusion width, are broken when sliced

In my model, I included a wall with a width of 0.45mm (1 extrusion width, as defined in PrusaSlicer). The CAD model looks correct, the STL model looks good, and the STL model looks correct when imported into PrusaSlicer, but when sliced in PrusaSlicer, the wall is broken. Please see the images.

What is the root cause of the broken walls?

How do I produce a sliced object that keeps the 0.45mm wall intact?

0.45mm wall is intact when imported into PrusaSlicer:

0.45mm Wall is broken after slicing in PrusaSlicer:

I guess there is an issue with the 0.45 mm thickness, not being considered as a full 0.45mm in either the 3d Program or slicer...

Have you changed the scale factor?

Ideally I would increase the part to a slightly lager size to ensure success !

Try changing the extrusion width to 0.42 for external perimeters, see if that helps... (Who knows, 0.44 extrusion width may work)

it's probable that there is a minor mismatch between expected size and realised size...

alternately set Prusa slicer to Expert mode, then go to Print settings > Advanced and change the XY size compensation to say 0.2mm

this may help... this setting effectively enlarges parts marginally...

Good luck,

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Model designed with walls of 1 extrusion width, are broken when sliced

Hi joantabb-

Thank you for your rapid reply.

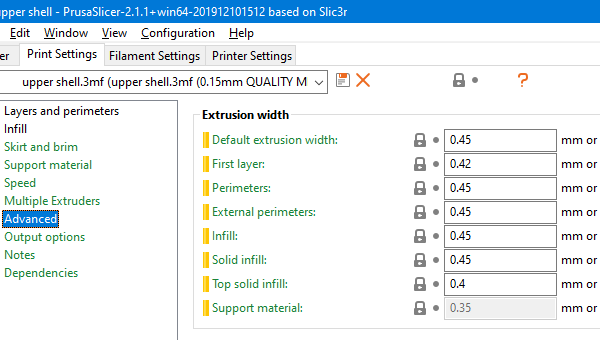

I had already selected the Expert option and revealed the extrusion widths. I am using the default settings for 0.15mm Quality MK3, and modified to align the seams and 100% infill. I haven't made any other setting changes.

All the extrusion widths are 0.45mm, except for the first layer and top solid infill, which shouldn't affect the wall in my object.

I don't want to modify any scaling, globally or in the X or Y plane; the part is being scaled to fit another part.

I could try to increase the wall thickness, iteratively, to see when it is not broken, but I am inclined to adjust my model to remove the wall. If I have time, I will come back and iterate the wall thickness until it doesn't break and report back.

Do you think my observation has revealed the need for an improvement in PrusaSlicer?

Prusa i3 MK4S Kit in Lack Enclosure

RE: Model designed with walls of 1 extrusion width, are broken when sliced

You might also try Print Settings->Layers and perimeters->Quality->Detect thin walls. As Joan notes, you can crank back the perimeter extrusion widths under Print Settings->Advanced. You should be able to go down to 0.4mm with a 0.4mm nozzle without problems. Any smaller gets tricky.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Model designed with walls of 1 extrusion width, are broken when sliced

Hi bobstro-

I will give the Detect Thin Walls a go and report back.

The tooltip for Detect Thin Walls says "True" is the default, but the box is not checked...perhaps a bug?

I will report back.

Prusa i3 MK4S Kit in Lack Enclosure

RE: Model designed with walls of 1 extrusion width, are broken when sliced

Update: Detect Thin Walls is the solution!

The walls are no longer broken (see image). There are a few dropouts on one wall (circled in green), but I can live with that.

I am very happy to have resolved my issue.

Thank you joantabb and bobstro for your help.

Prusa i3 MK4S Kit in Lack Enclosure

RE: Model designed with walls of 1 extrusion width, are broken when sliced

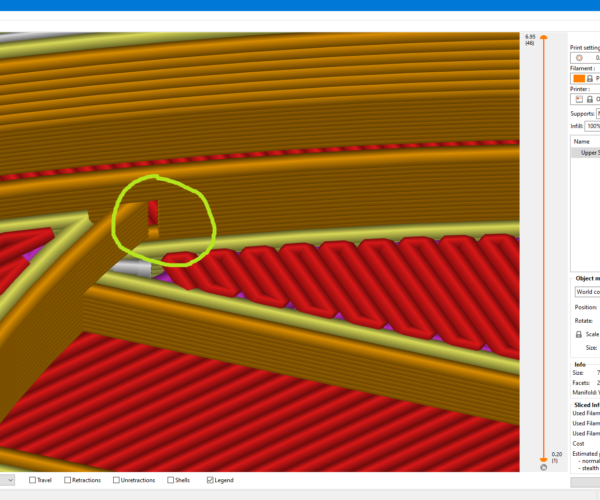

Update of Update: Nearly there.

Although the wall appears to be intact, there is a gap in the wall that is not in the model.

Is there another setting I should apply to remove this gap? Reducing the "Slice gap closing radius" had no affect.

Prusa i3 MK4S Kit in Lack Enclosure

RE: Model designed with walls of 1 extrusion width, are broken when sliced

Best would be to save a 3MF project file, zip it up and upload it here so we can see everything. Otherwise, we more or less have to take stabs in the dark.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Model designed with walls of 1 extrusion width, are broken when sliced

Great idea, bobstro.

Here is the zipped project file.

upper shell 4 extrusions per lip with 1 extrusion wall between pcb and lip pocket.3mf

Prusa i3 MK4S Kit in Lack Enclosure

RE: Model designed with walls of 1 extrusion width, are broken when sliced

I tried everything I could think of to get that to slice without those gaps in Prusa Slicer (2.2.0 Alpha4 and 2.1.1), to no avail.

I then tried it in Slicer++ which is based on the current Prusa Slicer and it sliced fine. No gaps and the thin walls looked ok with the same saved project.

Personally I think Prusa Slicer has issues around thin walls and where they meet as I've seen it with a couple of my models too. I usually end up trying those in Slicer++ as even though its based on the same code it seems to handle them better at the moment. Of course it can have its own issues but between the 2 I can usually get something that works.

I hope Bob or Joan can figure out something that works for you.

RE: Model designed with walls of 1 extrusion width, are broken when sliced

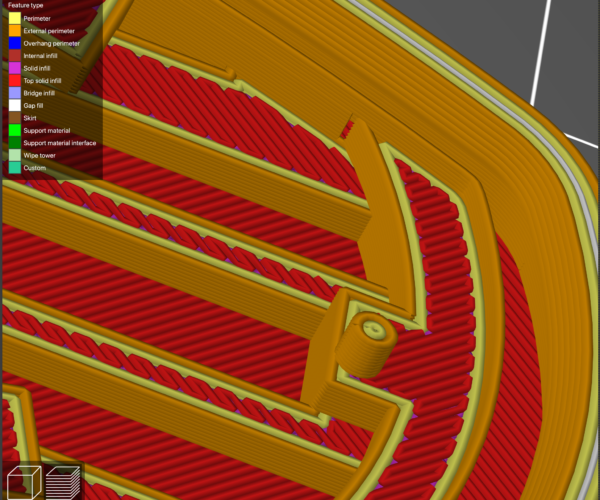

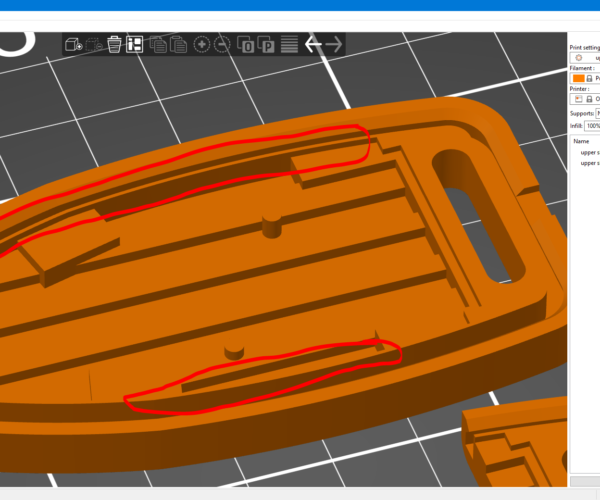

Your part has a lot of very thin walls that will be difficult to print consistently with a 0.40mm nozzle. I used a 0.50mm nozzle to exaggerate the effect:

Using a 0.25mm nozzle, that particular gap closes although others remain:

That particular gap opened up but another appeared. Not sure what's up. You might open an issue over on the PrusaSlicer github pages. That said, those are very thin walls and print with some distortion. Any chance you can modify the design to use more robust walls?

I'm using PrusaSlicer 2.2.0-alpha 4.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Model designed with walls of 1 extrusion width, are broken when sliced

Cura is also struggling with those thin walls. Here's a preview sliced with a 0.40mm nozzle profile:

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Model designed with walls of 1 extrusion width, are broken when sliced

Thank you for investigating, bobstro. I printed the object and it prints beautifully, with no distortion. I am using a 0.40mm nozzle with PLA on a Prusa i3 MK3S.

The gap I have is quite small and does not affect integrity, but is still troublesome, considering neophyl saw no gaps using a different slicer.

Do I need a new account to report an issue on github?

Prusa i3 MK4S Kit in Lack Enclosure

RE: Model designed with walls of 1 extrusion width, are broken when sliced

Github is separate to the Prusa infrastructure so your account here isn’t valid there.

btw if you want to give slicer ++ a go it’s here https://github.com/supermerill/Slic3r/releases. It’s built on the latest versions of Prusa Slicer so it has all the same stuff but also some extra options. It is organised slightly differently though. The good thing is that it’s possible to import all the same profiles in to it and it saves all the settings to its own directory so you can run both Prusa slicer and slicer++ side by side. It’s pretty painless switching between them. Also supports ironing amongst its extra stuff.