[Feature Request] Professional Alignment Tools

Very often I find my self plating up a dozen unique objects for printing. I don't like using Auto-arrange for a couple reasons:

- It looks random. Which might be okay if it optimizes print time, but there's other problems...

- It's less efficient. I can pack things in 50-60% tighter if I think about what goes where

- It can put rectangular objects diagonal which causes dual axis movement that could just be single

- It doesn't consider which side of the objects it best to face the edge of the build plate. I think if one side overhangs for example, that side should face the plate edge so that the colder edge of the plate isn't in contact with as much object.

- It won't nest objects. Very often I have objects with large hollows that could nest other objects easily to maximize production of a single print. I think auto-arrange treats each object like a rectangle of its maximum possible dimensions.

- I always have items "off to the side" that I plan to print on another day or maybe already did but haven't verified they came out all right. I use the location of each object (on the plate or not) as a boolean for "do I want to print this or not"

I start my own jobs but I'm not the person who takes them off the printer. I'd like that person to arrive to a nice looking plate that doesn't look like I was on a moving boat when I was laying things out. And I don't want to spend hours reading and typing specific offset numbers in by hand.

I propose a couple tools to help us professionally prepare multiple objects for printing:

- Highlighting/alerts when objects are "too close" to each-other (buffer distance select-able by user)

- Enable/disable-able snap to grid

- Snap to edge or centerline of plate

- Snap to edge or centerline of other object (with buffer distance)

- Select group of objects and "align x/y/z axis"

- Select group of objects and "space evenly along x/y/z axis

#'s 2-6 are basically things that Google Draw and various word processors do, which seems an odd thing to emulate here, but i think this sort of tidyness can make better use of the build plate, and elevate the perception of 3d printing that much more.

What do you think?

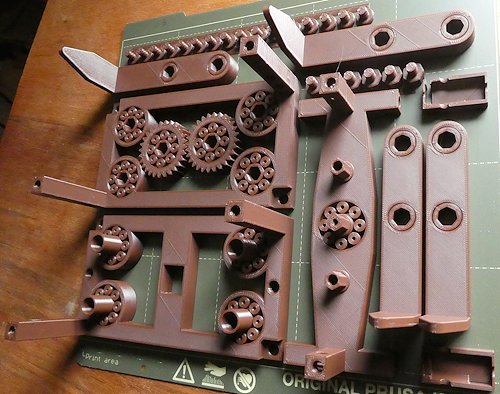

Where dense packing is required I find it easier to align a bed-full in the design software and then export the whole plate as one file. Thats how this was arranged:

From: https://www.printables.com/model/255791-basic-walker-walking-construction-toy

To make it more flexible I sometimes split the file in the slicer and re-save.

Cheerio,

RE: [Feature Request] Professional Alignment Tools

There is already this request https://github.com/prusa3d/PrusaSlicer/issues/4501 from July 2020 which has a large part of what you are asking for (but your list is more comprehensive). This one for parts nesting https://github.com/prusa3d/PrusaSlicer/issues/8225

Another for aligning on arrange https://github.com/prusa3d/PrusaSlicer/issues/8104

There are loads of issues open and closed around the arrange function.

RE: [Feature Request] Professional Alignment Tools

Nice job! I'm admittedly novice still but I feel like alignment for printing should be done in the slicer not in cad. For example if it's all one STL then wouldn't they all have to have the same brim/support settings. Unless you slice the stl apart in the slicer but then you're undoing what you did before. I'd also say that in my layouts, it's fairly rare that I could actually draw one plane through the build space and not end up cutting one model in half. I pack a LOT onto the build plate to keep the printer occupied for 12-18 hours.

This reminds me of Formlabs Preform and Chitubox. There's some talk of Chitubox having better placement options for supports, but chitu can't print to a Form3 printer so some say to generate supports in chitu and export stl and import into Preform to print withOUT adding supports in preform, but that's jenky because preform should just be better, and the formlabs printers should just support libre software slicers....

RE: [Feature Request] Professional Alignment Tools

You don't cut it apart. You would use either split to parts function, which keeps it still as one stl but does allow you to move individual parts around or use split to objects function which separates them into logical objects.

If you don't know the difference between objects and parts in PS and how it treats them differently then thats another thing to learn 🙂

if it's all one STL then wouldn't they all have to have the same brim/support settings.

Again, when it matters the brim and support is designed in CAD. The generic supports made by slicers are rarely going to be optimal and the paint-on options are merely transferring a CAD operation to the slicer where the printer user may not appreciate the requirements.

For example; if you look closely at the picture above you will see that the screws are all attached to custom brims to keep them attached and organised.

Cheerio,