Feature request - combining different layer height on external and internal perimeters

Hello everyone,

I am working with 50 3d printers, doing some serial production.

Currently I am working on speeding up the process.

I already manage to setup parameters and printers to work with a nozzle of 0,9mm in diameter, without loosing surface quality.

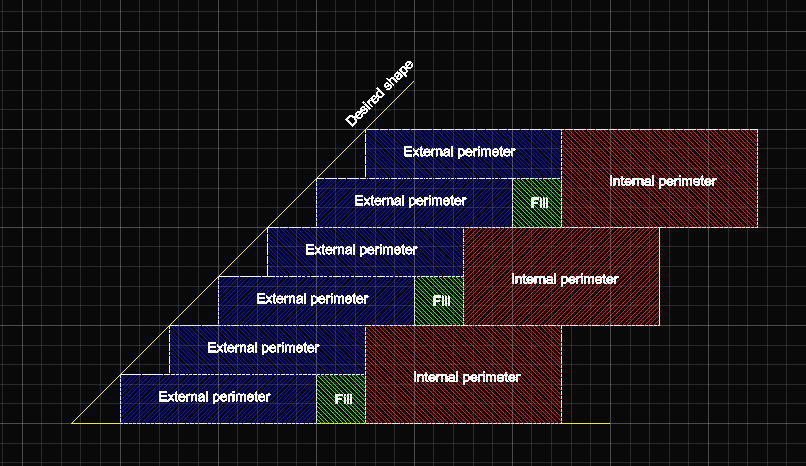

My idea is to use different layer height on external perimeters and internal perimeters (infill included, basically everything that is not visible from the outside).

On the picture above, you can see that external perimeters have height h, while internal perimeters are nh (where n is the number of external perimeters (whole number)).

That means the flow of printing would be:

Lets assume that we use 0,4mm nozzle and we want to combine 0,1 and 0,2mm layer height.

Printer prints first external perimeter of 0,1mm layer height, then a second layer of external perimeter of 0,1mm, then it prints inside part of an object with a height of 0,2mm same way as it normally does.

After all that is done, printer starting to print second layer, same way as the first, on top of the first layer, and so on.

What we get with that, we get nice looking surface of 0,1 layer height, but faster printing because internal part of an object is printed with 0,2 layer height.

Another sequence could be:

Printing of a first layer of external perimeter of 0,1mm lh (layer height), then printing internal perimeters and infil with 0,2mm lh, and then printing second layer of external perimeter with 0,1mm lh.

So basically what we do, is that we printing with 0,2mm layer height everything but external perimeters, which are n times thinner than internal perimeters. So we have fast printing and good quality on the outside of the object.

Another question is what to do if vertical walls are not parallel to the z axis.

In this case you can add fills as it is shown on the picture above. The size of the fill depends on the angle of the wall.

Please, let me know what you think about that idea?

RE: Feature request - combining different layer height on external and internal perimeters

Slicer currently supports combining infill layers to do what you describe, but only for infill. One issue with doing it on perimeters is that you would have to print outer perimeters first which is the reverse of what is normally done. There's an option to do that but I have never used it so I'm not sure what effect it has on models. I would expect though that it would play havoc with sloping overhang walls as there wouldn't be as much plastic for it to print against like the is when you go from inner to outer.

Why don't you post your idea as a feature request over on the Prusa Slicer github page as that's where the official place is.

RE: Feature request - combining different layer height on external and internal perimeters

Gap fill won't work as suggested... and overall I don't see the reason for the effort. That said, feature requests should be posted over on GitHub. Discussions here are good, but devs don't look here when picking up new ideas.

RE: Feature request - combining different layer height on external and internal perimeters

As @neophyl notes, a similar capability exists in PrusaSlicer today. If you look under Print Settings->Infill->Reducing print time->Combine infill every X layers you can tell the slicer to skip and combine multiple infill layers as you've described. However, this comes with a few caveats, and physics still apply.

If you want good inter-layer adhesion, you want to ensure there is some squish on each layer to provide adhesion with the underlying layers. If your layer height is too high, you start printing essentially circular extrusions with minimal contact between layers. A general guideline is that you should restrict layer heights to 80% of nozzle size. In order to maintain this ratio, you want to restrict your external perimeters to a fraction of that amount based on how many infill layers you want to skip. Assuming a 1.0mm nozzle and printing infill every 2nd pass, you'd want to use a maximum layer height of 0.80mm for infill, and thus half that 0.40mm for external perimeters.

I've played around with this technique and it does work. It works best with larger nozzles. Any speed gains are offset somewhat by the need to print perimeters -- often the slowest part of a layer -- at lower heights, increasing overall print times.

In your proposal, the same considerations would apply to inner perimeters instead of infill, in which case concerns about adhesion and part strength are amplified. Infill is often just providing support for overlying layers and the strength of the infill isn't critical. Perimeters are essential to overall part strength, so you have less flexibility.

You might want to spend some time checking out KISSlicer. One of its features -- at least as I understand it -- is to print variable layer heights that differ between different parts on the bed. This assumes that your maximum layer height for any parts is within the 80% recommendation (or close to it). KISSlicer simply skips extruding the "odd" layers on adjacent parts. Overall, the slicer will create more layers throughout the entire bed of parts, but many of those will not print anything on parts. I'm stuck on the road this week, but here's a rough sketch of how it works (at least as I understand it):

The solid horizontal lines represent parts that are extruded on a pass at that height and dotted lines are skipped. The result is more layers being printed, but extrusions only made where needed for each part. Layers would be printed at 0.2, 0.3, 0.4, 0.6, 0.8, 0.9, 1.0 and 1.2mm heights.

I'm sure I botched the description (awakened by a beeping trucks at 5:45AM), but it's a very clever approach that I haven't seen in other slicers. @PJR can surely provide more detail on KISSlicer than I can. Unfortunately, I've had to abandon KISS due to other concerns, but it incorporates some excellent ideas. I think the KISS approach illustrates the pros and cons of your proposal very well.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Feature request - combining different layer height on external and internal perimeters

No it’s not a feature. It’s been an open feature request on GitHub, In fact there have been several duplicates of the request.