Extrusion width problem

Hi All,

I've got a self build printer to print with clay. I'm using PrusaSlicer for slicing my models. My nozzle size is 3 mm. Everything is fine with layer height 1,5 mm, 1 mm. But when I'd like to slice with 0,5 mm layer height the path becomes thinner... Is there any minimum limit in layer height? I don't think so. I've also got Prusa MK3S printer and with 0,4 mm nozzle one can go to 0,05 mm layer height so this is 1:8 ratio.

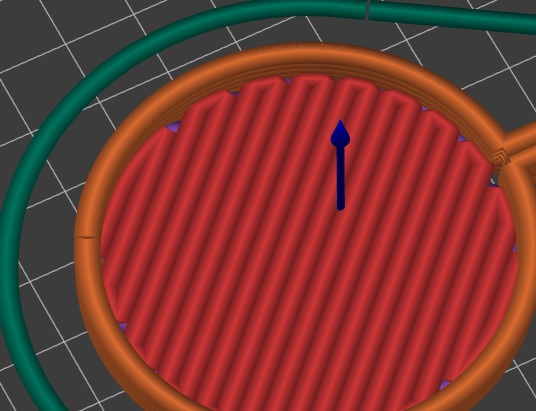

Photo 1. Sliced with 1 mm layer height.

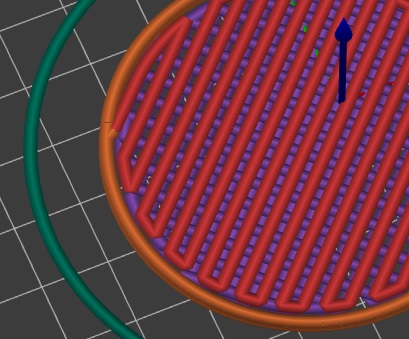

Photo 2. Sliced with 0,5 mm layer height

RE: Extrusion width problem

if you save your prusa slicer setup, for the 0.5mm layer height, including the model, as a .3mf project file, (file>save project as...)

then zip compress the project file,

you should be able to attach your zipfile to your next post, and l;et us have a play with the file.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Extrusion width problem

Thank you Joan,

Here is my file (do it for the first time, hope it works).

Arek

RE: Extrusion width problem

Good morning Arek,

have you actually tried printing at 0.5mm layer height? or are you basing your enquiry on the slicer images alone?

I have no experience of 'huge' nozzles.

the spacing between the rows of filament seem to remain pretty close at the different layer heights but the trace widths seem to vary widely,

I am wondering, is the slicer expecting the nozzle to 'squish' the extruded clay wide enough to fill the gaps?

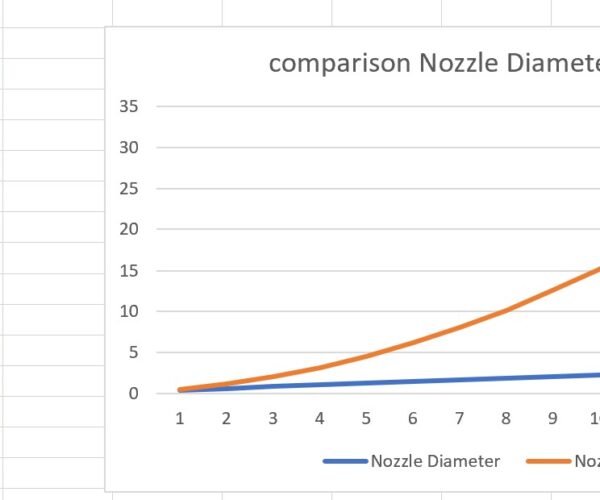

below I am considering area alone, because the different lengths of an extruded filament will create a linear change, as the length changes

As a nozzle diameter increases in a linear manner the area of the nozzle does not increase in a linear manner so your comparison of a 0.4mm nozzle to a 3,0mm nozzle may not be a valid comparison

I Suspect that the difference in extrusion width in comparison to changes in extrusion thickness will not be linear... ( I believe your expectations of similar(Linear) 'ratiometric' (is that even a word?) values between a 0.4mm nozzle and a 3mm nozzle may be flawed...

hopefully someone with more mathematical knowledge than me, will step in...

best wishes with your project

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Extrusion width problem

Thanks for you answer. I haven't tried printing but maybe you're right that the quantities per E steps are good. I'll do some math. Maybe it is only some PrusaSlicer path rendering bug. But I still wonder why all works great for 0,4 mm nozzle and let's say 0,05 mm layer height (1:8 ratio). My ratio - 3 mm to 0,5 mm is 1:6...

Regards, Arek

RE: Extrusion width problem

I did the calculations and found out the extruded volumes in generated g-code are ok. My results and PrusaSlicer are the same. So I suppose PrusaSlicer renders wrong path widths... I will make real world test soon. Thanks for help.