Sample STL

...if you post the STL, I'll print it on my setup and if it works well I'll post back the 3MF that includes all the print settings.... but this will be for eSun ePA-CF.

Sample STL

...if you post the STL, I'll print it on my setup and if it works well I'll post back the 3MF that includes all the print settings.... but this will be for eSun ePA-CF.

...actually, I'm not sure this will help as I had a look at the specs of PA12-CF and it is different to other blends of PA-CF (it claims to be less hydrosopic but poorer Mechanical and Thermal specs). I have both eSun's ePA-CF and ePAHT-CF but not ePA12-CF ( https://www.esun3d.net/products/495.html).

Happy to try however

Sample STL

I already printed it with only 30mm/s and tried also MVS with only 2mm³, but it doesnt works as i wish.

Sure can i post the STL =)

RE: STL Upload doesnt worked

@jmone

but i also tried a another STL...And you must not use/print your expensive PA12-CF15 only for testing for me ...

STL Upload doesnt work, so i uploaded it there:

https://we.tl/t-xsOCPyArnl

Sample STL

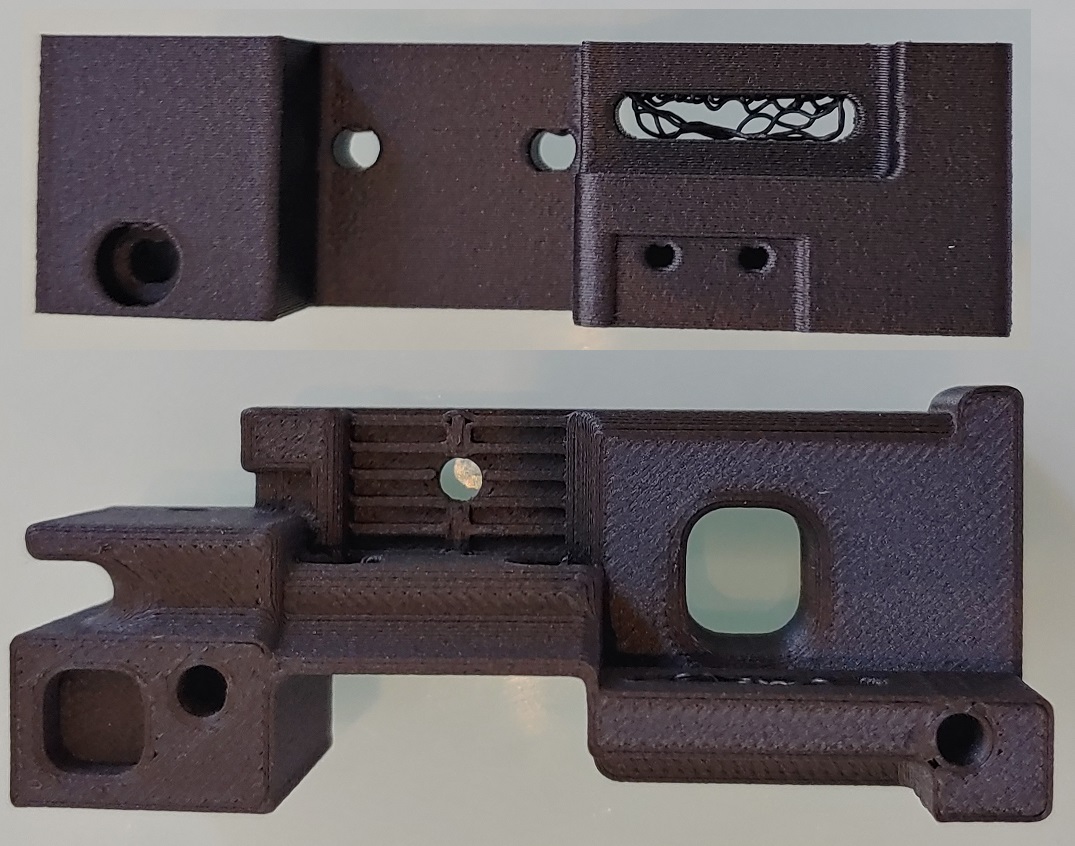

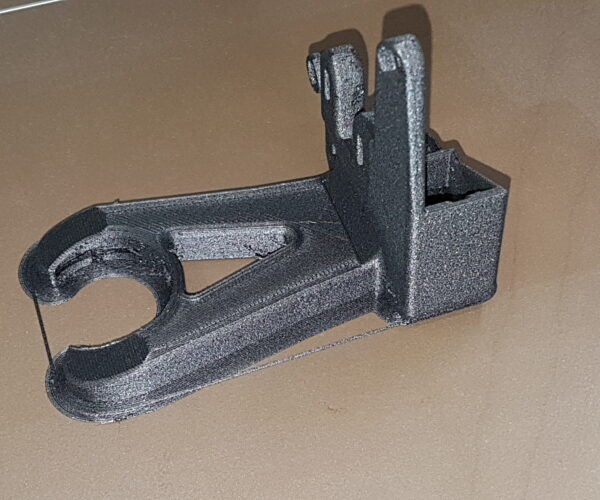

I've got your sample and I'm currently printing the Right Carriage using the end of a spool of eSun ePA-CF (so it is a different type and Brand of PA. I'll post a photo and some comments when it is finished. For now, here is my 3MF file where you can see the settings and compare (but my setup is a an MK3S/MMU2 with a Mosquito Magnum Hotend + High Temp Thermistor + Tungsten Carbide Nozzle).

Sample STL Print

The model printed well (I did not use supports, brims etc) and here is a photo of it straight of the Build Plate. There is some issues around the long bridge but apart from that the layers and finish look great. Like all ePA-CF prints it feels very strong and light weight.

Thank you Jmone

Good Morning,

THank you so much @Jmoe

For Time & Testing & also using you expensive Filament for me ❤️

I tried yesterday again a half day but, then i gave up.

I think it is really the 0.4 Nozzle.....

I will save you 3mf FIle, and compare it / have a look at it on the evening =)

Thanks again, that is not a matter of course & no one has ever done something like this for me =)

Kind Regards

RE: Your Welcome

No problems, it's all about the community helping each other out.

If you can afford a Tungsten Carbide nozzle then it is a very good upgrade, far better than Hardened Steel for Thermals, and very abrasive resistant. They are the only nozzles I use, and I use them on all types of filaments. The One Nozzle to Rule them All!

Good Luck.

Nozzle size?

No problems, it's all about the community helping each other out.

If you can afford a Tungsten Carbide nozzle then it is a very good upgrade, far better than Hardened Steel for Thermals, and very abrasive resistant. They are the only nozzles I use, and I use them on all types of filaments. The One Nozzle to Rule them All!

Good Luck.

@jmone thank you for all the great info in this thread. What size of nozzle do you use? I have the 0.4 Nozzle-X, will your profile be a good starting point for me to try with the ePA-CF ?

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Sorry for the late replay, I missed you post! I have a range of sizes and find 0.4 and up is fine. I mostly use the 0.4 for detailed work, and 0.8 for speed.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

No Problem, thanks for your answer =)

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Great thread!

I'm also getting into printing with Esun PA6-HT-CF

I'm getting great results out of it, except bridging. I see you have the same issues in the example part printed above.

Any pointers to fix the bridge first layer spaghetti?

I've tried fan off, 50%, 100%, bridging speed 20mm/s, 30mm/s, 60mm/s, bridge multiplier 0.96, no luck making any change really

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

I just add supports and the knock out pretty cleanly.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

When needed or bear needed, ePA-CF is tough to print without supports.

I just add supports and the knock out pretty cleanly.

--------------------

Chuck H

3D Printer Review Blog

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

What makes bridging so hard with Nylon? Is it because the melting point is so narrow?

ie, too cold, goes brittle, to hot, goes liquid...? PLA on the other hand has a very wide spectrum where it's just a rubber band..

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

What makes bridging so hard with Nylon? Is it because the melting point is so narrow?

ie, too cold, goes brittle, to hot, goes liquid...? PLA on the other hand has a very wide spectrum where it's just a rubber band..

I am not a material expert but I suspect it has something to do with the high temperature.

--------------------

Chuck H

3D Printer Review Blog

RE:

I print this nylon at 240/90 on my old MK3: Carbonnylon 3DXTech

Printing plate I used the original Prusa satinized without adhesive. Used a 0.4mm tungsten carbide nozzle -> https://www.3dmakerengineering.com/collections/3d-printer-nozzles/products/tungsten-carbide-3d-printer-nozzle?variant=14784857145399

The ruby also works quite well.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Ok... a slightly off topic question.

Has any of you had this filament turn soft after printing? A few items I printed at the time of my last reply to this thread has turned SUPER soft... I printed a bridging test scroll, and it's fully pliable now... Few other little things have gone soft too. I mean, soft like PVC cable jackets... it holds shape, but can bend a lot

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

I have had PLA Items go soft in the sun...

or on a radiator

could higher temperature be the issue

PLa has a low glass transition temperature

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Googling this turns up results that other people have same experience, I think there is a bad batch out.

My parts were great after printing, then going soft over time after that. The parts have not been warm at all, just in normal ambient indoor temperature. Basically like soft licorice now.. and it's supposed to be 170MPA, PA6 HT CF... I think it's a moisture absorbance problem. I've contacted my supplier to see if I can get the spool replaced.