RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Are you using octoprint with a camera?

--------------------

Chuck H

3D Printer Review Blog

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@kenny-3

I have changed the settings to do the infill first followed by outer parameter working inwards. Thinking this might help.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@flo4print

Doesnt seem to be a temp issue as theres no stringing at all

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@cwbullet

No but i can be?

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@flo4print

Doesnt seem to be a temp issue as theres no stringing at all

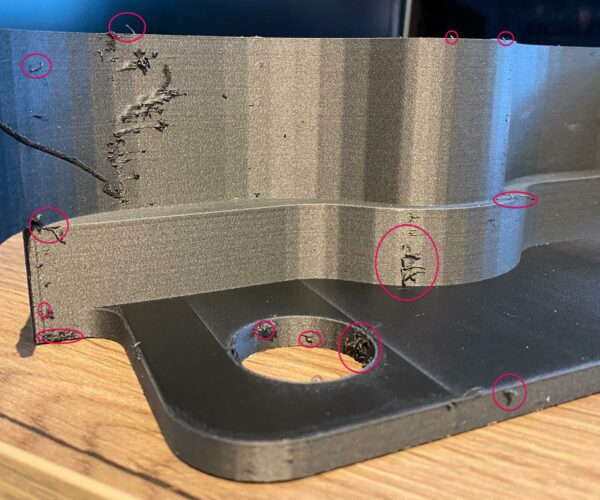

We can see a lot of oozing on pictures, typical for this filament.

I have this picture of a print of mine in stock, you can see the same phenomena :

This is not temperature, nylon is much more fluid, subject to oozing. This is not stringing.

MK3S & Fusion 360

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@joeski

My printer puts a line on once side of the print as it moves out fo the way to take a photo. I had to increase retraction.

Re looking at the photos - this is not the same pattern i have.

--------------------

Chuck H

3D Printer Review Blog

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

can you guys upload your profiles for me to try?

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

I would but I am away from my printers for the Holiday.

--------------------

Chuck H

3D Printer Review Blog

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Here you can find 2 files, and export bundle of my eSunCF filament profil + a 3mf of a cube

PrusaSlicer_config_bundle_eSunCF

MK3S & Fusion 360

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

thank you greatly flo!

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

Hi. Can you share your prusaslicer settings for eSun ePACF-HT filament?

Regards,

FFdez

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@ffdez

Here you go (exported 3MF model)... FWIW, my setup also M3s/MMU2 + Slice Magnum + HT Thermistor + TC Nozzle so while the ePA6-CF filament profile may be of use I'm guessing it will need further tweaking on other setups.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

Thanks. I'll try and let you know.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

I did use the setting for a spur gear to see differences between Prusa PLA and eSunPAHT-CF. Got same dimensions, good print, just both prints are a little bit shrink versus the original drawings. How can I work with shinkage in order to achieve the same dimensions as the drawing?

Regards,

ffdez

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Print looks pretty good. I've not noticed issue with dimensions but then again I've also not been printing parts that require tight tolerances. That part could be a good way of determining what % shrinking you are getting in the X Y Z print orientations (note: it could be different in all three planes). What % change do you get?

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

I found this info on shrinkage for Injection Moulding and PA6 with GF is listed as between 0.3-1% on one table and 0.4% on another.

https://www.taiwanmoldmaker.com/solution/plastics-shrinkage-rate-mold-shrinkage-rate

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@ffdez

Couple of other things that may impact it:

- I keep my filament in an industrial near 0% RH cabinet so my filaments are bone dry when printing (which is what you need) though you print looks fine.

- The models after printing will absorb moisture and this is required for the parts to reach full strength. I've measured the weight gain over time, but did not think to measure how the dimensions change. I did not run the test on the ePA6-CF but on the std ePA-CF it gained almost 5% in weight over a couple of weeks in a 80% RH environment.

Here is an article that may be of interest - https://www.ptonline.com/articles/dimensional-stability-after-molding-part-4

So I'd suggest you need to leave you gear print as is and see how the dimensions change (if at all) over a couple of weeks.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

Hi. More or less 0.003"/1"

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

Hi. I did place the spool into a dehidrator @ 70C for 24 hr, then into a Sunlu filadryer at 55C while printing. I did a couple more samples at 100.5% and 102%. 101.5 is short and 102 is above. I'll find it.

One question: prusaslicer change all three XYZ parameters at same time. Is there a way only to change X or Y or XY and not Z %?

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@ffdez. There is a little Lock Icon in the scale factor, if you "unlock" it by clicking on it you the can change X Y and Z independently. When locked it will change all three together.