eSun ePA-CF, Carbon Fibre Slicer Profile.

Hi Guys,

Just got a roll of ePA-CF ( http://www.esun3d.net/products/278.html ), printing with it just using the standard PETG profile in Slicer, as the temps are pretty much the same, and it's going ok so far except for stringing and bridging.

Anyone got a tuned profile for this filament, I'm using a MK2.5S. TIA! 😀

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

This is my favourite structural filament and it prints beautifully....once it is dry! Have a read of this thread - https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-general-discussion-announcements-and-releases/drying-times-and-temps-in-dehydrator/

I can almost guaranty that the filament (straight out of the box) is simply not dry enough. Symptoms are poor bridging, stringing, an almost spongy balsa wood type feel to it, poor layer adhesion etc. I've posted some pics in the thread linked above of what it can look like. My profile - (MK3s/MMU2S with a TC Nozzle on a Mosquito Hotend) is not that different from PETG but:

- Extrusion Multiplier: 0.96 or 0.98

- 260c Nozzle / 90c Bed

- Cooling 30min, 60 max disabled for 1st layer

- If still issues with Stringing, on the Filament Overrides, increase length to 2.5 and Retration Speed of 50 (note: I don't need this for ePA-CF but it helped on ePA-GF though I don't think my spool was properly dry at the time either - yet to retest my ePA-GF now it is fully dry without the Filament Overrides).

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

Nice, I'll give them a go. The first print I did was straight after I opened it, it actually came out extremely well, strong as heck, and perfect dimensions. The only issue was the bridging and ooze. Have never printed with nylon before and there are no default prusa settings to start from.

How do you find adhesion? I can get it to stock to the PEI sheet for love nor money 😛 I ended up printing the first layer in PETG then printing on that, worked perfectly, and released well when cool. I think I'm going to order some soluble support filament and put down a bed of that first, then print on to that, see how it goes.

I'm really loving the rigidity of this filament for functional parts, just need to tweak those few issue and I think it'll be my go to filament.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Isn't ePA a polyamide, which is Nylon? Do Nylons print with the same profiles (temperatures, linear advance K value, volumetric flows, cooling, etc) as PETG? Wouldn't Taulman Bridge be a better starting point?

(I'm asking because I honestly don't know...)

See my (limited) designs on:

Printables - https://www.printables.com/@Sembazuru

Thingiverse - https://www.thingiverse.com/Sembazuru/designs

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@ kenour - No problem with adhesion with a little hair spray on a textured sheet. I actually have one side evenly coated with Hairspray and the Other without anything. Most prints stick better with on the hair spray side.

@ sembazuru - I checked and my starting profile was the Prusament PETG to which I then modified. I great good speeds and really really good quality from these settings. I can post my profile if that helps but my setup is not stock so the general gist may be better.

I've been banging on about this filament for a while now. As kenour says, I can not believe how good this filament is. It's tough, looks great, is easy to print (once you get it sorted and dry), dimensionally accurate, low warp and great heat deflection (only bettered by PEEK which I tried and failed to print on a Prusa with mods). I've replaced all my hotend parts with eSun EPA-CF (click on the image to see more detail)

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

I also got some eSun ePA-GV (Nylon Gass Fibre) and have been dialling that it. More info in this thread - https://forum.prusa3d.com/forum/original-prusa-i3-mmu2s-mmu2-how-do-i-print-this-printing-help/esun-epa-gf-weird-hue-changes-on-layers/ but as you can see as the spool got dryer the quality just got better (stringing almost disappeared and bridging was fine).

These ePA (Nylon) with CF (Carbon Figre) or GF (Glass Fibre) are very good, as long as you like Black or Cream that is!

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Isn't ePA a polyamide, which is Nylon? Do Nylons print with the same profiles (temperatures, linear advance K value, volumetric flows, cooling, etc) as PETG? Wouldn't Taulman Bridge be a better starting point?

(I'm asking because I honestly don't know...)

Yes the PA include Nylon but the eSun ePA range have a lower printing temp that straight Nylon (so it has been modified somehow) and it is similar to PETG (hence why I started with that one as a base profile). The only stats I have on the eSun ePA-CF is from their info:

Characteristics:

- Environmentally friendly, Nylon based, 20% carbon fiber;

- Printing smoothly, odorlessness, matte finish printing effect;

- High Strength, High Rigidity, Good Toughness, Wear Resisting, Fitting to 3D print industrial parts;

- HD T Top 160℃, then suitable for the high temp occasion;

- Compared with Nylon, it has lower shrink rate and distortion, high accuracy without warped edge;

- Good flame resistance, Flame-retardant level: UL94-V2;

- Stainless steel nozzle shall be needed instead of quick-wear bronze nozzle when using CFRPA filament.

- Print Temp: 240-260

- Bed Temp: 80

- Density: 1.24

- Heat Distortion: 120c

- Melt Flow Index: 10 g/10min

- Tensile Stregth: 75 MPa

- Elongation at Break: 26%

- Flexural Strength: 122 MPa

- Flexural Modulus: 5160 MPa

- IZOD Impact Strength: 12 kJ/m3

I also have a spool of Dupont Zytel (PA 6) and it too is tough as nails but much more expensive and I print that at 270c and used the Poymaker PC-Max (for some reason I've forgotten but probably it was the closest at the time for Print Temp) as the basis for my tweaks on this filament.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

I've got a print running at the moment with the suggested settings, I'll let you know! Cheers.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Nice. Did you get a change to dry it first?

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

I'll put it in the dehydrator tomorrow, I only opened it yesterday. It's going pretty week with the settings you provided except for a bit of stringing. But nothing a bit of post processing can't sort out 😉

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Nice (I presume you mean "It's going pretty well....")! - it will only get better the dryer it is. And from my experience, they are all less than dry out of the box.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

I have a roll. I will have try these settings.

--------------------

Chuck H

3D Printer Review Blog

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

@jmone

I DID, I DID MEAN THAT!!! 😛

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

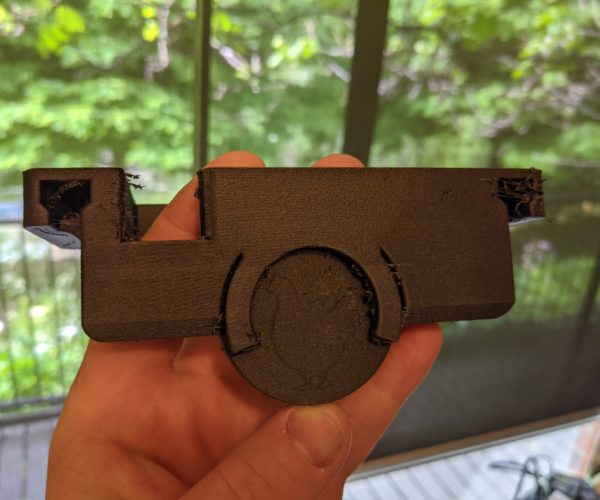

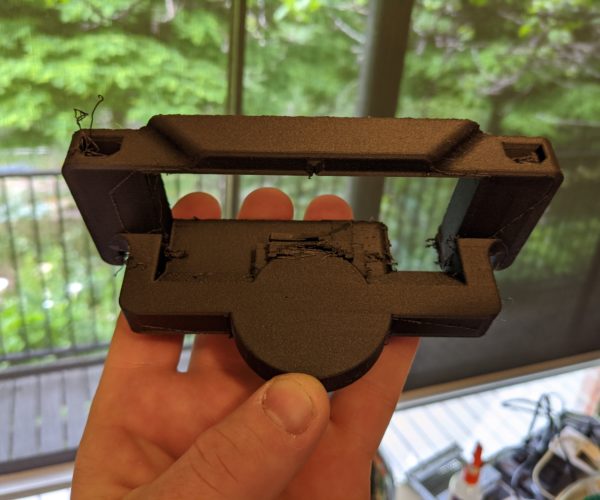

🙂 + photo or it did not happen!

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

🙂 Always Happy! your right, still some stringing etc. I should print a Benchy for reference but I'm away with work for a couple of days.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

Always happy? I can't manage occasionally content! You must have access to the good drugs.

RE: eSun ePA-CF, Carbon Fibre Slicer Profile.

I being trying to think of a witty comeback but.... you have me beat!