Confine support structure to inside the part outline

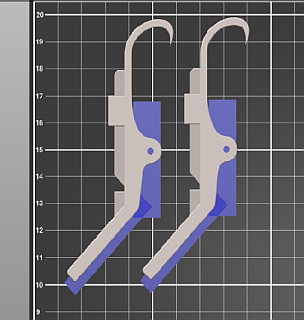

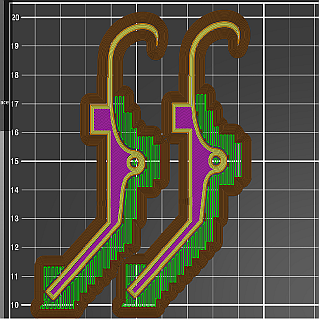

I am using PrusaSlicer 2.2.0, I would like to confine all the support structure inside the part outline, the part upper face is a mirror of the lower face with significant overhang portion, like a U channel, I want the support to stack off the lower profile without overlapping onto the plate. As you can see, the brim is now outlining the support structure outside of the part outline which is using excessive filament and time to print. The images are from 2 copy parts I am printing.

RE: Confine support structure to inside the part outline

Try using Plicer 2.3.0.2 alpha. It has paint on supports, and allows a bit finer control where supports are placed. Or, use support enforcers, as they can also be minimized to limit where supports are generated - and sometime help when AUTO places supports everywhere in crazy ways.

RE: Confine support structure to inside the part outline

I don’t think there’s a whole lot you can do short of switching to another slicer. I have found PS to produce excessive supports. With optimized settings (just search for support settings in this forum) there are going to be very easy to remove but PS still likes to produce a lot of supports on the outside. I’ve only used the new paint on future in the alpha a few times and didn’t feel that aggressive behavior had changed much.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Confine support structure to inside the part outline

The support behaviour hasn't changed at all in 2.3. Its only the mechanism to determine how support enforcers and blockers are applied to areas of the model that has. Once those areas are defined the support generation algorithm is the same. I agree that is it VERY aggressive and that the defined support enforced areas have to be much smaller to limit the growth outwards, which isnt always possible.

RE: Confine support structure to inside the part outline

That's where the paint function is handy. You can paint one small dot to minimize the invasiveness. No, it doesn't always work, but is the best option I've found so far in Plicer.

I'm still waiting for tree supports to be available for FDM. Until then, Meshmixer works when I really need to minimize what is or isn't supported.

RE: Confine support structure to inside the part outline

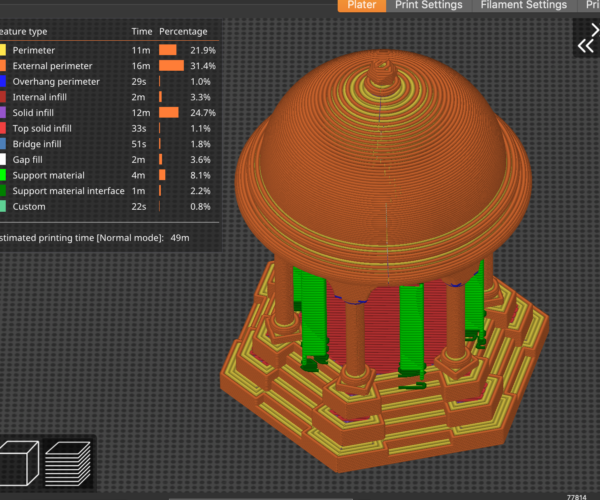

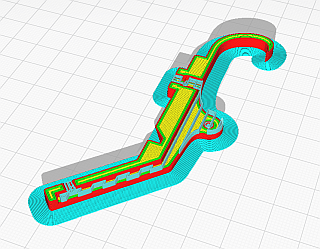

Just a couple of quick pics showing the increased ease of use and control with paint-on support enforcers. Here's Prusa's default support structure:

Here are the results with paint-on support enforcers. I put a small dot a the peak of each arch:

Of course, you need to test to see if the resulting smaller supports actually support everything adequately, which may take more time than simply printing with the originally generated support.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Confine support structure to inside the part outline

@bobstro

That looks pretty impressive. Still, I wish we didn’t have to use paint-on as a band-aid and instead see the devs rethink the support algorithm.

Another thought: while PrusaSlicer is a much better slicer than FlashPrint, FlashPrint actually has a very nice “paint-on style” mechanism for generating custom tree supports.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Confine support structure to inside the part outline

[...] That looks pretty impressive. Still, I wish we didn’t have to use paint-on as a band-aid and instead see the devs rethink the support algorithm.

The Devs may not consider it broken in the current implementation, preferring to err on the side of "better too much than too little" when auto-generating support. You can tweak it if desired but it should work in most cases. Tweaks to the interface are much appreciated, but I like the paint-on approach better than any other I've seen.

I've used most of the mainstream slicers and none generate perfect supports automatically. Some have a few more features than PrusaSlicer, but still require tweaking on some prints.

Another thought: while PrusaSlicer is a much better slicer than FlashPrint, FlashPrint actually has a very nice “paint-on style” mechanism for generating custom tree supports.

What is different about FlashPrint's approach?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Confine support structure to inside the part outline

@bobstro

Nothing fancy, you basically draw a line from the model surface to the bed surface and the slicer will put a tree branch along that line. Obviously you have to know what you're doing or you may end up with trees that collapse while being printed or ones do not provide enough support. It's not the default in FlashPrint but an expert option.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Confine support structure to inside the part outline

@fuchsr

Similar to how MeshMixer allows painting tree supports. But MM also allows adding and editing the auto-supports, too.

RE: Confine support structure to inside the part outline

@tim-m30

I just wish MM had a better user interface, and I would use it a lot more often...

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Confine support structure to inside the part outline

Thanks everyone for your replies. I thought and just confirmed Cura supports do exactly what I was asking. It seems logical not to carry supports down to the build plate when not necessary, seems wasteful, time and filament wise as well as clean up where the supports may contact the walls on the way down to the plate, which I assume can be adjusted out from the wall. It surprises me more users don't have an issue with the support structure lapping over the part outline when support is only needed between faces.

RE: Confine support structure to inside the part outline

Another aspect of PrusaSlicer in having the brim outline the support structure outside the part outline is that the brim becomes useless when held away from the part. When printing with PolyMax I need the brim to hold the part down as intended.