Circle (round arch) top

Hi guys,

Sorry I'm new to all the printing stuff.

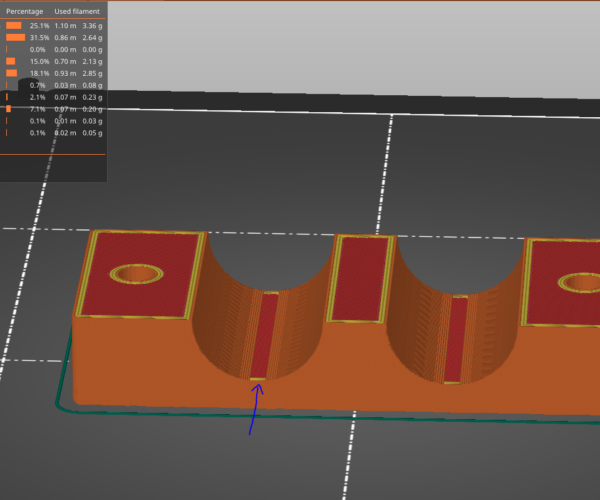

I'm trying to print a hose clamp, but the topmost part always looks strange. I tried different settings but with no luck.

Even the 0.05 setting looks identical to the 0.2mm

Is there any hint you can give me to make the circle .. like a circle?

Have you tried rotating the part and putting the nearer face as pictured, at the bottom?

Cheerio,

RE: Circle (round arch) top

It’s the nature of slicing a circle into discrete layers. You could rotate it like Diem suggests, but personally I wouldn’t. For one, it will move the flat spots to the bolt holes. Two the clamping force would then be against the layers, the part is weakest in that orientation so as it is now is best for strength. The usual thing is to post process them by sanding the flat spots to shape or you make the circle bulge at those spots to compensate for the layering process. It’s common for the tops of circles to have a little triangle section added for cutouts. For example https://3dprinting.stackexchange.com/questions/250/how-to-print-an-overhanging-arc.

RE: Circle (round arch) top

Thank you for your answer.

Yes I did, then the big circle looks "perfect", but the other don't.

I want to print it in with the upper side facing down, so that i get a very flat surface where both parts touch each other in the end... that's my plan for now, based on my limited knowledge

RE: Circle (round arch) top

@metzlmane

You need to increase the resolution of the model in that area, If you designed it, then take it back into your 3D modeling software and add more sections, you can actually see the sections as they are in the slicer, and the slicer can only slice what you give it. If you didn't model the part, or you don't know how to 3d model, you may have a chance at using a Negative Volume in slicer to increase the resolution in that area. BTW the area is red and looks different because it's top solid fill.

However given that you mention this is a hose clamp, I'm going to suggest to you that you print the part as it is and see how it goes, the hose it most likely pliable and will still get the compression you need.

Regards

Swiss_Cheese

The Filament Whisperer