Can't Get Rid of the Whispy Strings

Hello,

I am trying to switch to PrusaSlicer from S3D. I've been building a profile for my Ender 5 Pro using the default Ender 3 as a starting guide. I'm getting reasonable good print quality but can't get rid of these whispy strings.

When I print the same cube with S3D it comes out just fine.

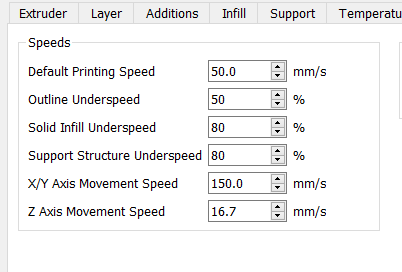

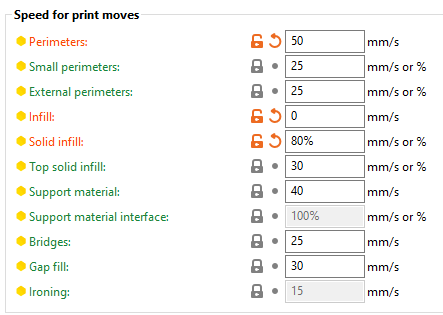

The settings are not quite the same but here are my settings for retraction and speed for both slicers

I've tried different retractions up to 9mm and speeds faster and slower. I'm a little at a loss what to change anymore. Overall I like PrusaSlicer as it's producing better prints except for the strings.

Thanks,

Jason

RE: Can't Get Rid of the Whispy Strings

Is there any difference in temperature between the two?

RE: Can't Get Rid of the Whispy Strings

No sorry. Both are 200 End and 60 bed.

RE: Can't Get Rid of the Whispy Strings

One of my next steps would be to print out one of those temperature and bridging towers using both methods. See if there's any difference between the temperature for the best bridging and least stringing between the slicers.

I'm assuming that the filament and environmental factors are EXACTLY the same for both, correct?

RE: Can't Get Rid of the Whispy Strings

Yes. Same filament, inside an enclosure, same roll. Temp and Stringing towers look best at 200. Printed one from PS, then S3D and then PS. The S3D didn’t have strings so I’ve eliminated most of the factors. I’ve calibrated e-steps twice, my bed is level. The major difference is in PS I’m doing a lift. Maybe that’s causing the issue. I added the Z lift based on a post here but maybe I need to try it without again. It’s interesting that some stringing tests are fine but this cube and the benchy are not.

RE: Can't Get Rid of the Whispy Strings

I notice your s3d settings also contain a minus extra distance on restart that your PS settings don’t have in them. Have you tried adding that ?

RE: Can't Get Rid of the Whispy Strings

So it appears that the z-lift was causing the issue. I was led down a rabbit hole by another post on here suggesting that z-lift would help and I never looked back. I removed the z-lift and the cube is coming out well. I'm going to print another benchy but I think I have a good profile now. Thanks for all that answered.

RE: Can't Get Rid of the Whispy Strings

There are a lot of slicer features that are intended to help with stringing:

- retraction and de-retraction length

- retract/de-retract filament speeds

- wiping

- z-lift or z-hop

- coasting (Cura)

These are workarounds to deal with over extrusion that contributes to stringing when the nozzle is moved away from the print. After struggling with this same problem, I realized that it's better to deal with the over extrusion in the first place. The closer your slicer settings reflect your actual printer and filament settings, the more your print will look like your slicer preview. In chasing this down, I belatedly realized that disabling most of these features and focusing on my extrusion multiplier was the key. I've been able to almost completely eliminate fine stringing when I need to (details here). Prusa has a procedure here and I describe another approach in my notes.

The key notes are:

- Measure, average, and enter your actual filament diameter into the slicer.

- Do a calibration print to measure the amount extruded versus your slicer settings and adjust your extrusion multiplier accordingly.

- Be sure your filament isn't saturated with moisture as that can throw the calibration off due to inconsistent extrusion.

You can reduce stringing from over extrusion with slicer features. You can eliminate stringing from over extrusion by calibrating your extrusion multiplier. Since making this a standard practice, I've reduced retraction to 0.2-0.4mm (Prusa direct drive), z-lift to 0.4mm, and completely disabled wiping. I believe the Ender 5 uses a Bowden setup, so you'll need to determine appropriate lengths for retraction.

Other topics worth testing:

- Retract and de-retract speeds. Faster retract speeds can reduce nozzle pressure more quickly and can help. However, equally fast de-retract speeds may cause problems. I've increased retraction speeds to 50mm/s and de-retraction speeds to 25mm/s with good results. Again though, mine are direct drive setups.

- Travel movement. Faster travel movement (and associated jerk & acceleration) help pull the nozzle cleanly away and can help reduce stringing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…