Bad overhangs on a small ABS part

Hi

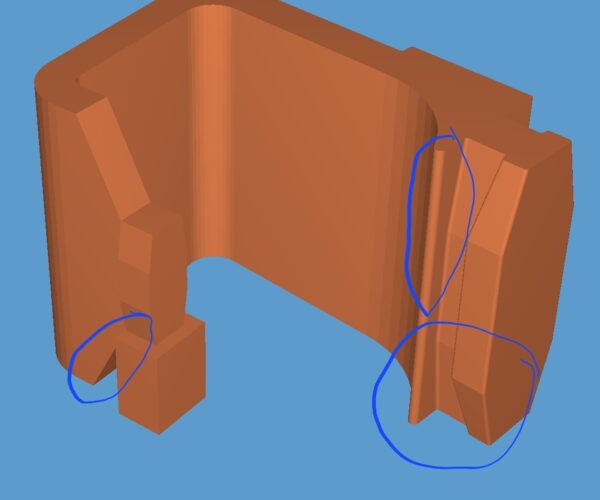

How can i print this small part in ABS or ASA, with 0,2mm layer hight, and get good overhangs?

I printed 2 of this part far away from another, so they get enough time to cool after each layer. But the overhangs curl up every time. No fan.

I got an enclosed printer and most bigger ABS parts come out good.

Is it even possible to get such a small part with overhangs in perfect "PLA quality" and good layer adhesion?

Can some from here please try to print that part in perfect quality and post the pictures and settings?

RE:

After hours of testing i find good slicer settings.

With Polymaker Polylite ASA black: 225-230°C. Buildplate temperatur 70°C with 3DLack on it and i opened the top cover of my enclosed printer. 20mm/s external perimeters. 25mm/s rest. The 2 Parts are 100mm away from another. 50-60 seconds layer time. No fan. And i add 2 modifier which lowered the infill on the marked details to 30% Cubic. Rest 95% infill.

RE: Bad overhangs on a small ABS part

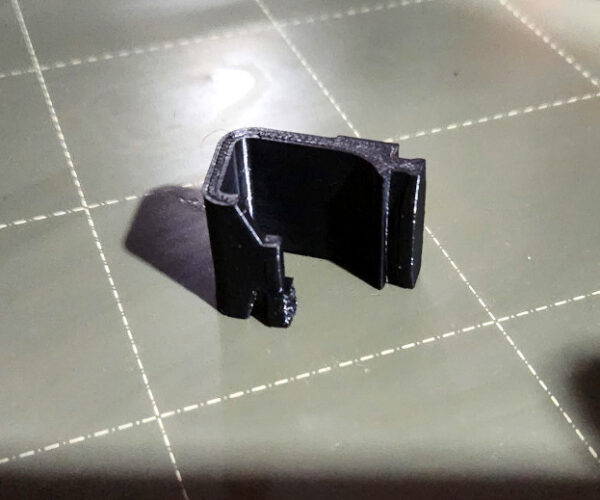

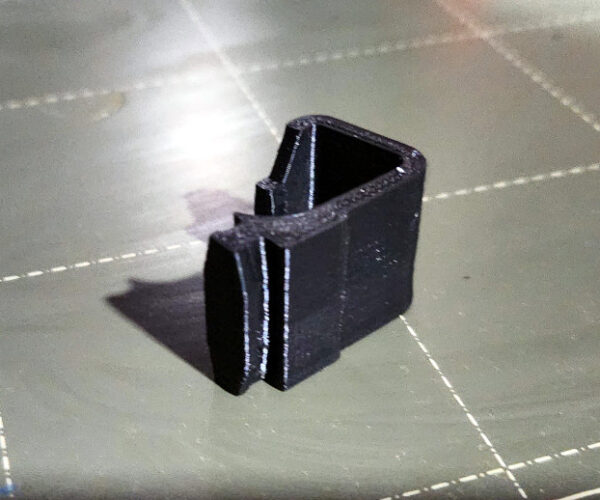

Coincidentally, I have black ABS loaded in the machine, and I gave it a quick try. Default settings.

It came out more or less as expected.

I assume that the one piece is a break-away support, correct? It broke away cleanly, with effort, but if I were doing this, I would have just used the slicer's break-away support for that.

RE: Bad overhangs on a small ABS part

Thank you.

Did you print one piece or 2 at the same time?

Was your fan on?

Under 50 seconds layer time my overhangs are curling up bad.

RE: Bad overhangs on a small ABS part

I have a very different philosophy than most others here when it comes to testing out a reported difficult print and trying to help another user.

I very seldom try to duplicate what the user did. I figure that we know what makes a bad print already, and I want to make a good print and let the user know what I did.

I almost always go back to square 1, with the original .stl and try what I would first do if it were my print.

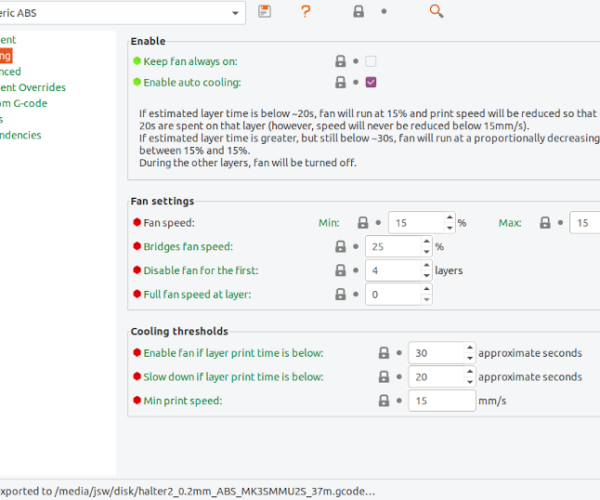

In this case, I used totally default settings for a generic ABS and let it print.

I only did one piece. I only wanted one to see how it would turn out, and I really saw no reason to try two just to make the machine juke around between two of them.

I'm including a screenshot of the fan settings, which are all defaults for the generic ABS profile that I've been using for several years. (You may need to expand it to see all of it.)

It's been my experience that in almost all cases for reasonably simple prints, there's seldom any reason to vary from the defaults.

Now I don't know if what I printed is what you would like, but it appears to me to be a faithful plastic rendition of what's in the .stl file, within the limits of the machine, of course. As I said, the only thing I would have done different is to use the slicer-generated break-away support instead of the drafted support in the model. I'm not seeing any drooping or any obvious temperature/cooling related issues.

I hope this helps.

Thank you.

Did you print one piece or 2 at the same time?

Was your fan on?

Under 50 seconds layer time my overhangs are curling up bad.

RE: Bad overhangs on a small ABS part

I just wanted to add my own 2 cents. I would strongly advise against opening the enclosure when printing ABS. This will almost certainly degrade layer adhesion substantially and it can increase warping. It is probably better to have a nice and warm enclosure and a modest part cooling turned on, like in jsw's settings. If things still don't look nice, printing slow is an almost universal solution, also printing multiple copies at once can help.

Mk3s MMU2s, Voron 0.1, Voron 2.4

RE: Bad overhangs on a small ABS part

I would agree to keep the enclosure shut unless there is a compelling reason to do otherwise.

A couple of other things I do with ABS prints is to first preheat the machine and let it sit for 20 minutes or so to stabilize before launching the print.

Then, when the print finishes, I always let it cool to almost room temperature before attempting removal.

If you do not have an enclosure, the draft shield actually works quite well for smaller parts. It's available in both PS and Cura.

Also, always use a release agent. I learned the hard way on that one!

RE:

I tried again with the closed cover and 70°C bed temperature. The part came out good with better layer adhesion. Maybe a bit more curling on the small overhangs... but a strong part is also important. So i will use that setting in future.

I made another print with 100°C bed and closed cover and the overhangs turn uglier.