@swiss_cheese, given the screenshot to sort of see what you're doing I was able to get it to work out differently after trying a bunch of things. I had to lay a 2 layer, 30x30x.4, cylinder on top of the inner one and that would force it to be an "exterior" solid layer instead of an interior bridged layer. It looks exactly as I was wanting and will give this a try.

@r-2

If for whatever reason it ends up not coming out the way you want, I can pass the one I did to you, and you can see what I did.

it might help you get there.

I'm printing one in Ninjaflex (water) right now, just because.

Regards

Swiss_Cheese

The Filament Whisperer

@swiss_cheese, Ok, I have it slicing exactly as yours looks. But the cylinder in the center says 4 walls yet shows none, just single "infill" surrounding. If I change that cylinder to have 3 or 5, or any number that isn't 4, it goes back to the ugly slicing and having walls.

What gives with the wall count negating walls when it's equal to the main settings wall count? Also, this behavior gets even more buggier. If you have 9 of these objects only the last one added doesn't print the walls, the prior 8 will have walls and do the separated top/bottom exterior/bridge layer behavior.

For comedy sake, here's a project that shows this is likely broken.

@r-2

If the modifier your using is set to (0 Zero) perimeters, then the perimeter amount it uses defaults to the amount specified in: Print setting/Layers and Perimeters/Vertical shells: perimeters. in the case of the .3mf you uploaded you have 3 set, so Zero will produce 3 perimeters for the modifier area.

if you enter 1 in the perimeters for the modifier this will produce 4 perimeters, 3 from Print setting/Layers and Perimeters/Vertical shells: perimeters, and one "external" from the modifier input.

If you enter 2 in the perimeters for the modifier this will produce 5 perimeters, 3 from Print setting/Layers and Perimeters/Vertical shells: perimeters, and 1 "external perimeter" and 1 "perimeter" from the modifier input for a total of 5.

Matching the perimeter amount in the modifier will in effect cancel out the perimeters for the modifier, leaving only the perimeters from Print settings/Layers and Perimeters/Vertical shells: perimeters, in the areas where applicable. in your models case the outer perimeters. and letters.

There's nothing buggy about it, the model that wasn't acting like the other has it's settings changed, it's the only model in the bunch that has it's modifiers perimeter settings set to (0 Zero).

This is normal Prusa slicer behavior it's not broken, you can fight it if you want, you can call it what you want, but it is consistent and results are very reproducible. I think you need to take some time to understand the software, and not just think everything is broken because it's not meeting your notion of how it should be. it's a very powerful slicing software, and yes it is still being developed. you have other options if it's not to your liking, but you will find folks here willing to help you learn its ins and outs.

You can control the perimeters on the outside of the model separate from the modifier if you want to, via use of another modifier, these things take time to learn.

I'm not at my computer today, so Couldn't produce an example of this.

Good Luck

Swiss_Cheese

The Filament Whisperer

Can you direct me to where this behavior is documented?

@r-2

Can you direct me to where this behavior is documented?

Unfortunately NO, and I say it like that because I'm not at all happy with the documentation or lack there of. This software has some minor points of documentation in the prusa knowledge base, but its very underwhelming, I am however doing what I can about it in the form of tutorials and explanation to the best of my ability. I believe others are as well. I learned, and am learning through hours and hours of use and playing/experimenting for the past several years. you would almost learn more about the software by just following its progress and playing hard with it, as it seems you have been, and then sharing your insights with others and them you.

Good luck, if you do find something you deem worthwhile please pass it on.

Regards

Swiss_Cheese

The Filament Whisperer

Yeah, about what I expected but I figured asking was worthwhile. I can't say I've been very happy with any of how these modifier meshes work when on the same layer in different locations. The last one does behave differently and in some cases any prior to the last one are entirely ignored or the layer doesn't even print where they are, eg they act like print blockers. Not intuitive at all, so I'll probably have to go read the code to see what the intentional behavior is.

Multicolor as in switching filament or some sort of MMU?

@R - I just realized you're probably not using a Prusa MMU. When you refer to multicolor, do you mean switching filament at a preset height or are you using some sort of MMU/Palette?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

What firmware is your printer using?

Perhaps this is a matter of setting or using the correct firmware, currently your .3mf is showing your firmware to be Marlin, is your A8 printer using Marlin firmware to match?

Regards

Swiss_Cheese

The Filament Whisperer

@bobstro : This printer I do M600's, it's a single extruder/single input. I do have a single extruder/triple input printer but that's not the one I'm using on this print currently or you would see a wipe tower enabled in the project 😉 (I have a serious hate/love relationship with that printer)

@swiss_cheese : Yes, all of my printers run Marlin 2.0.x bugfix, the last time I flashed the one I'm using for this it was 2.0.8 versioned.

For reference, I've used Slic3rPE/PrusaSlicer for about 4 years but I do not own any Prusa printers. Mostly Anet's, a Geeetech, and a custom Ender'ish type clone. I love it for nearly everything I do but occasionally the pathing irks me. Lack of combining layers like this post thread is about, lack of starting a layer at the same X/Y as the last layer completed at, some of the bridging not always anchoring correctly. I did once ask for a feature and got rebuffed, so I didn't bother anymore. I'm annoyed enough lately that I'm going to sit and look at the source and play there some, same as I do for work stuff. This should be fun 😉

👍

Ok, I thought it might be worth mentioning.

Just for fun mind if a take a shot at trying to fix up the file, I'm still kinda guessing at what your really looking for here, but I think can get the models to print all on the same bed with the features shown in the clear one I printed. if your looking for the entire alphabet post it.

If not no worries.

good Luck, Have fun.

Swiss_Cheese

The Filament Whisperer

For reference

I sent Swiss the SCAD's. Got the compile working, I'll read through that for a while and if I can pick up on how it all works I may attempt documenting some things.

Alternatives for consideration

@bobstro : This printer I do M600's, it's a single extruder/single input. I do have a single extruder/triple input printer but that's not the one I'm using on this print currently or you would see a wipe tower enabled in the project 😉 (I have a serious hate/love relationship with that printer)

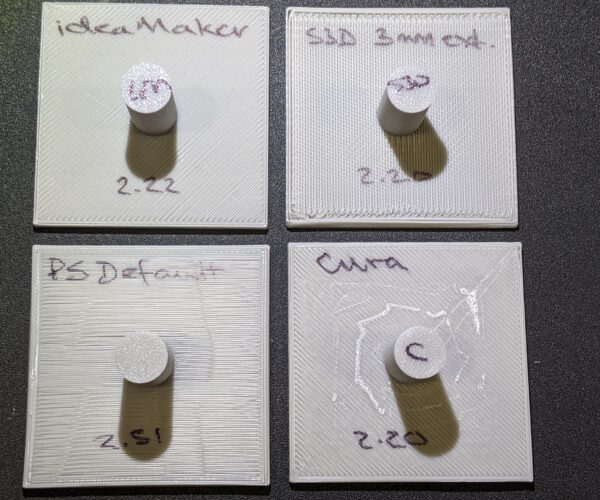

The reason I asked is that the bridging in PrusaSlicer/Slic3r was notoriously ugly, apparently for historical technical reasons that made sense at one time. Here's a quick comparison of supported undersides I did a while back:

- You mentioned that you don't like using Cura for multi-color prints. I found that ideaMaker does a very nice job with supports and bridging in many cases, and it does support the use of M600 for filament changes, albeit in its own quirky way. I'm a fan of PrusaSlicer, but do still switch over to ideaMaker for some specific prints. I just wanted to point you to a possible alternative.

- As you are no doubt aware, the upcoming release of PrusaSlicer 2.4, currently in Alpha, includes a number of changes to bridging specifically to address some of these problems. The "do not use thick bridges" feature sounds much like the fix you're after. If you're game for digging through source code, it might be worth starting with the current development release.

- You mentioned using transparent filament. I've never gotten FFF printing to produce "great" transparent results, but I am curious to see what you consider a "good enough" result. Do you have any pics of the result you're after, and ideally a comparison showing the problem you're having with PrusaSlicer?

I have done some "fridge magnets" to use on my whiteboard (I hate redrawing the same thing repeatedly) and tweaked the design based on your description. It may not be what you're after, but doing these as a snap-fit design allows for a much smoother underside on the (translucent?) top piece. The best bridge is no bridge, so I like to eliminate them in the design. Possible food for thought.

For reference, I've used Slic3rPE/PrusaSlicer for about 4 years but I do not own any Prusa printers. Mostly Anet's, a Geeetech, and a custom Ender'ish type clone. I love it for nearly everything I do but occasionally the pathing irks me. Lack of combining layers like this post thread is about, lack of starting a layer at the same X/Y as the last layer completed at, some of the bridging not always anchoring correctly. I did once ask for a feature and got rebuffed, so I didn't bother anymore. I'm annoyed enough lately that I'm going to sit and look at the source and play there some, same as I do for work stuff. This should be fun 😉

Given that PrusaSlicer was ported from PERL to C++, I'm sure it could use some code review and suggestions. I'm sure there's a lot of old cruft in there. The devs can seem terse, but having your notes on record is helpful. I can only imagine what their workday is like with some of the complaints that pop up here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

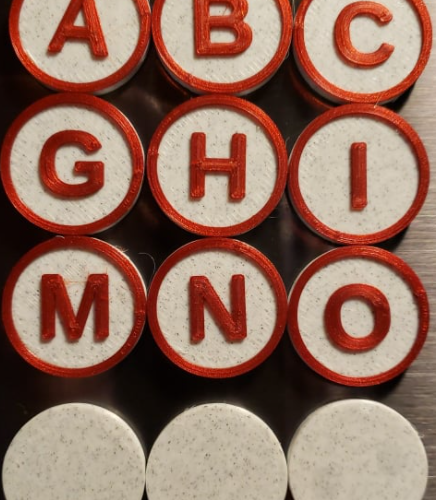

So here's the answer on multipart based on the @swiss_cheese method plus forcing the top 3 layers to all be "exterior." Not getting the bridge does do slightly thin lines over the infill but the next 2 layers cover that up when using solids. I'll probably increase infill for the transparent filaments and see how that goes. Made it user friendly in case anyone felt like reusing for a basic/simple magnet.

AlphabetMagnets SCAD

Some test prints with cheap filament on a 0.6 nozzle:

@bobstro : 'Yep' to all of that. That's definitely a nice design, though I have a requirement of the magnet needing to be unremovable and embedded. With yours I can't help but to think of putting small button cell & LED in the empty space for throwies. I have ideaMaker installed but haven't really ever printed with it, might give that a try just to see, though I'm already thinking of modifying PS's M600 support for my own use since I modify the gcode manually on those depending on the reason for the M600. Plus I copy the next Z/XY move to the front of M600 so it's in air over where it prints next and not putting a color dot in the last printed location upon return from home.

I totally understand the development stuff, I deal with a lot of that at work.

Considerations for tots

Given the subject matter, I assume these are intended for small children. Embedding the magnet inside makes sense as you don't want small things popping apart. I was pleased that the snap-fit cap stays in well enough for handling although it's not going to be "kid rated". The 2 part design (STL attached) was just an exercise in a different approach.

If you are doing prints for kids, do some stress testing if you haven't already. I had visions of doing 3D prints for young nieces and nephews, so printed up some test toys in PETG and PLA. I was shocked when I subjected them to a good whack with a hammer. Both materials shattered and produced nasty shards and small stringy fragments. Once printed into more solid pieces, the material takes on a much more rigid quality.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

There is an interesting article on crush ribs, a technique to join parts together allowing for tolerances.